I-Granite uhlobo lwedwala eliyi-igneous elimbiwe ngenxa yamandla alo amakhulu, ubuningi, ukuqina, kanye nokumelana nokugqwala. Kodwa i-granite nayo isebenziseka kakhulu - akuyona nje eyezikwele nezingxande! Eqinisweni, Sisebenza ngokuqiniseka ngezingxenye ze-granite ezakhiwe ngezimo, ama-engeli, nama-curve azo zonke izinhlobo njalo - ngemiphumela emihle kakhulu.

Ngokusebenzisa ukucubungula kwethu okusezingeni eliphezulu, izindawo ezisikiwe zingaba yisicaba kakhulu. Lezi zimfanelo zenza i-granite ibe yinto efanelekile yokwakha izisekelo zomshini zosayizi owenziwe ngokwezifiso kanye nomklamo owenziwe ngokwezifiso kanye nezingxenye ze-metrology. I-Granite yile:

■ okusebenziseka ngomshini

■ isicaba kahle uma isikiwe futhi isiqediwe

■ ukumelana nokugqwala

■ okuhlala isikhathi eside

■ okuhlala isikhathi eside

Izingxenye zegranite nazo kulula ukuzihlanza. Uma udala imiklamo eyenziwe ngokwezifiso, qiniseka ukuthi ukhetha igranite ngenxa yezinzuzo zayo ezinhle kakhulu.

IZINHLELO ZOKUSEBENZA EZINGAQONDWA KAKHULU / EZINGUQUKA KAKHULU

I-granite esetshenziswa yi-ZHHIMG emikhiqizweni yethu ejwayelekile yepuleti lobuso inokuqukethwe okuphezulu kwe-quartz, okunikeza ukumelana okukhulu nokuguguleka nokonakala. Imibala yethu Emnyama Ephakeme inamazinga aphansi okumunca amanzi, okunciphisa amathuba okugqwala kwama-geji akho okunemba ngenkathi usetha emapuletini. Imibala ye-granite enikezwa yi-ZHHIMG ibangela ukukhanya okuncane, okusho ukuthi amehlo awakhathali kakhulu kubantu abasebenzisa amapuleti. Sikhethe izinhlobo zethu ze-granite ngenkathi sicabangela ukwanda kokushisa ukuze sigcine lesi sici sincane.

IZICELO EZISEKELWE NGOKUZENZAKALELAYO

Uma uhlelo lwakho lokusebenza ludinga ipuleti elinezimo ezenziwe ngokwezifiso, izinto zokufaka ezinezintambo, izikhala noma okunye ukugaya, kuzodingeka ukhethe into efana neBlack Jinan Black. Le nto yemvelo inikeza ukuqina okuphezulu, ukudambisa ukudlidliza okuhle kakhulu, kanye nokusebenza kahle kokugaya.

Kubalulekile ukuqaphela ukuthi umbala wodwa awubonisi izimfanelo zomzimba zetshe. Ngokuvamile, umbala we-granite uhlobene ngqo nokuba khona noma ukungabikho kwamaminerali, okungenzeka kungabi namthelela ezimfanelweni ezenza izinto ezinhle ze-surface plate. Kukhona ama-granite apinki, ampunga, namnyama amahle kakhulu kuma-surface plate, kanye nama-granite amnyama, ampunga, napinki angafaneleki nhlobo ukusetshenziswa ngokunemba. Izici ezibalulekile ze-granite, njengoba ziphathelene nokusetshenziswa kwayo njengezinto ze-surface plate, azihlobene nhlobo nombala, futhi zimi kanje:

■ Ukuqina (ukuphambuka ngaphansi komthwalo - okuboniswa yi-Modulus of Elasticity)

■ Ubulukhuni

■ Ubuningi

■ Ukumelana nokuguguleka

■ Ukuzinza

■ Ukubhoboka kwe-Porosity

Sivivinye izinto eziningi ze-granite futhi saqhathanisa lezi zinto. Ekugcineni sithola umphumela, i-granite emnyama yaseJinan iyinto engcono kakhulu esike sayazi. I-granite emnyama yaseNdiya kanye ne-granite yaseNingizimu Afrika zifana ne-Jinan Black Granite, kodwa izakhiwo zazo zomzimba zincane kune-Jinan Black Granite. I-ZHHIMG izoqhubeka ifuna izinto eziningi ze-granite emhlabeni futhi iqhathanise izakhiwo zazo zomzimba.

Ukuze ukhulume kabanzi nge-granite efanele iphrojekthi yakho, sicela uxhumane nathiinfo@zhhimg.com.

Abakhiqizi abahlukene basebenzisa amazinga ahlukene. Kunezindinganiso eziningi emhlabeni.

I-DIN Standard, i-ASME B89.3.7-2013 noma i-Federal Specification GGG-P-463c (Amapuleti Omphezulu We-Granite) njalo njalo njengesisekelo semininingwane yawo.

Futhi singakha ipuleti lokuhlola ngokunemba kwe-granite ngokwezidingo zakho. Siyakwamukela ukuxhumana nathi uma ufuna ukwazi ulwazi olwengeziwe mayelana nezindinganiso ezengeziwe.

Ukuthamba kungabhekwa njengamaphuzu onke ebusweni aqukethwe ngaphakathi kwezindiza ezimbili ezihambisanayo, indiza eyisisekelo kanye nendiza yophahla. Ukulinganiswa kwebanga phakathi kwezindiza kuwukuthamba okuphelele kobuso. Lokhu kulinganiswa kokuthamba kuvame ukuba nokubekezelelana futhi kungafaka phakathi ukubizwa kwebanga.

Isibonelo, ukubekezelelana kwe-flatness kwamamaki amathathu ajwayelekile kuchazwa ku-federal specification njengoba kunqunywe yifomula elandelayo:

■ Ibanga Lelebhu i-AA = (40 + isikwele esivundlile/25) x .000001" (esihlangothini esisodwa)

■ Ibanga Lokuhlola A = Ibanga Lelebhu AA x 2

■ Ibanga Legumbi Lethuluzi B = Ibanga Lelebhu AA x 4.

Kumapuleti obuso obukhulu obujwayelekile, siqinisekisa ukubekezelelana kobuthambeka okungaphezu kwezidingo zalesi sichasiselo. Ngaphezu kobuthambeka, i-ASME B89.3.7-2013 kanye ne-Federal Specification GGG-P-463c zibhekana nezihloko ezifaka: ukunemba kokulinganisa okuphindaphindiwe, izakhiwo zezinto ze-granite yepuleti lobuso, ukuqeda kobuso, indawo yokusekela, ukuqina, izindlela ezamukelekayo zokuhlola, ukufakwa kwezifakelo ezinezintambo, njll.

Amapuleti okuhlola e-granite e-ZHHIMG kanye namapuleti okuhlola e-granite ahlangabezana noma adlula zonke izidingo ezibekwe kule ncazelo. Okwamanje, akukho ncazelo echazayo yamapuleti e-angle e-granite, ama-parallels, noma ama-master square.

Futhi ungathola amafomula ezinye izindinganiso kuLANDA.

Okokuqala, kubalulekile ukugcina ipuleti lihlanzekile. Uthuli oluvuthayo oluvela emoyeni luvame ukuba umthombo omkhulu wokuguga nokuklebhuka epuletini, njengoba luvame ukungena ezicucwini zomsebenzi kanye nasezindaweni zokuthintana zama-gages. Okwesibili, mboza ipuleti lakho ukuze ulivikele othulini nasemonakalweni. Isikhathi sokuguga singandiswa ngokumboza ipuleti uma lingasetshenziswa, ngokujikeleza ipuleti ngezikhathi ezithile ukuze indawo eyodwa ingatholi ukusetshenziswa ngokweqile, nangokufaka ama-contact pad ensimbi endaweni yokulinganisa ngama-carbide pads. Futhi, gwema ukubeka ukudla noma iziphuzo ezibandayo epuletini. Qaphela ukuthi iziphuzo eziningi ezibandayo ziqukethe i-carbonic noma i-phosphoric acid, engancibilikisa amaminerali athambile futhi ishiye imigodi emincane ebusweni.

Lokhu kuncike endleleni ipuleti elisetshenziswa ngayo. Uma kungenzeka, sincoma ukuhlanza ipuleti ekuqaleni kosuku (noma emsebenzini) bese uphinda futhi ekugcineni. Uma ipuleti lingcola, ikakhulukazi ngoketshezi olunamafutha noma olunamathelayo, cishe kufanele lihlanzwe ngokushesha.

Hlanza ipuleti njalo ngesihlanzi sepuleti esingenamanzi noma i-ZHHIMG Waterless surface plate. Ukukhetha izixazululo zokuhlanza kubalulekile. Uma kusetshenziswa isinyibilikisi esiguquguqukayo (i-acetone, i-lacquer thinner, i-alcohol, njll.) ukuhwamuka kuzopholisa ubuso, futhi kuphazamise. Kulesi simo, kuyadingeka ukuvumela ipuleti ukuthi lijwayeleke ngaphambi kokulisebenzisa ngoba kuzokwenzeka amaphutha okulinganisa.

Isikhathi esidingekayo ukuze ipuleti libuyele esimweni salo sizohluka ngobukhulu bepuleti, kanye nenani lokubanda. Ihora elilodwa kufanele lanele amapuleti amancane. Kungadingeka amahora amabili kumapuleti amakhulu. Uma kusetshenziswa isihlanzi esisekelwe emanzini, kuzoba nokubanda okubangelwa ukuhwamuka.

Ipuleti lizogcina namanzi, futhi lokhu kungabangela ukugqwala kwezingxenye zensimbi lapho zithintana nobuso. Abanye abahlanzi bazoshiya nensalela enamathelayo ngemva kokuba yomile, okuzodonsela uthuli oluphuma emoyeni, futhi empeleni kwandise ukuguguleka, kunokuba kunciphise.

Lokhu kuncike ekusetshenzisweni kwepuleti kanye nendawo elikuyo. Sincoma ukuthi ipuleti elisha noma isesekeli se-granite esinembile sithole ukulungiswa kabusha okugcwele kungakapheli unyaka owodwa wokuthenga. Uma ipuleti elingaphezulu le-granite lizosetshenziswa kakhulu, kungakuhle ukufinyeza lesi sikhathi sibe yizinyanga eziyisithupha. Ukuhlolwa kwanyanga zonke kwamaphutha okulinganisa okuphindaphindiwe kusetshenziswa izinga le-elekthronikhi, noma idivayisi efanayo kuzobonisa noma yiziphi izindawo ezigugile ezikhulayo futhi kuthatha imizuzu embalwa kuphela ukusebenza. Ngemva kokuba imiphumela yokulungiswa kabusha kokuqala isinqunyiwe, isikhathi sokulinganisa singandiswa noma sifinyezwe njengoba kuvunyelwe noma kudingwa uhlelo lwakho lwekhwalithi yangaphakathi.

Singakunikeza isevisi ukukusiza ukuthi uhlole futhi ulinganise ipuleti lakho le-granite surface.

Kunezimbangela eziningana ezingaba khona zokwehluka phakathi kokulinganiswa:

- Indawo engenhla yagezwa ngesisombululo esishisayo noma esibandayo ngaphambi kokulungiswa, futhi ayizange inikwe isikhathi esanele sokulungisa isimo sayo.

- Ipuleti alisekelwanga kahle

- Ukushintsha kwezinga lokushisa

- Ama-draft

- Ukukhanya kwelanga okuqondile noma okunye ukushisa okukhulu ebusweni bepuleti. Qiniseka ukuthi ukukhanya okuphezulu akufudumezi ubuso

- Ukwehluka kwe-gradient yokushisa evundlile phakathi kobusika nehlobo (Uma kungenzeka, yazi izinga lokushisa le-gradient evundlile ngesikhathi kwenziwa ukulinganisa.)

- Ipuleti alivunyelwe isikhathi esanele sokujwayela ngemva kokuthunyelwa

- Ukusetshenziswa kabi kwemishini yokuhlola noma ukusetshenziswa kwemishini engalinganisiwe

- Ushintsho ebusweni olubangelwa ukuguguleka

Kumafektri amaningi, amakamelo okuhlola kanye namalebhu, amapuleti obuso be-granite aqondile athembelwa kuwo njengesisekelo sokulinganisa okunembile. Ngenxa yokuthi ukulinganisa ngakunye okuqondile kuncike endaweni enembile yokubhekisela lapho kuthathwa khona ubukhulu bokugcina, amapuleti obuso ahlinzeka ngendiza engcono kakhulu yokubhekisela yokuhlola umsebenzi kanye nokuhlelwa ngaphambi komshini wokugaya. Futhi ayizisekelo ezifanele zokwenza izilinganiso zokuphakama kanye nokulinganisa ubuso. Ngaphezu kwalokho, izinga eliphezulu lokusicaba, ukuzinza, ikhwalithi iyonke kanye nomsebenzi wobuciko kuzenza zibe ukukhetha okuhle kokufaka izinhlelo zokulinganisa eziyinkimbinkimbi zemishini, ze-elekthronikhi kanye nezokukhanya. Kunoma iyiphi yalezi zinqubo zokulinganisa, kubalulekile ukugcina amapuleti obuso elinganisiwe.

Ukulinganisa Okuphindaphindwayo Nokuthamba

Kokubili ukulinganisa okuyisicaba kanye nokuphindaphinda kubalulekile ukuqinisekisa ukuthi indawo inembile. Ukusicaba kungabhekwa njengamaphuzu onke ebusweni aqukethwe ngaphakathi kwezindiza ezimbili ezihambisanayo, indiza eyisisekelo kanye nendiza yophahla. Ukulinganisa ibanga phakathi kwezindiza kuwukusicaba okuphelele kobuso. Lokhu kulinganisa ukusicaba kuvame ukuba nokubekezelelana futhi kungafaka phakathi ukubizwa kwebanga.

Ukubekezelelana kwe-flatness kwamamaki amathathu ajwayelekile kuchazwa ku-federal specification njengoba kunqunywe yifomula elandelayo:

I-DIN Standard, i-GB Standard, i-ASME Standard, i-JJS standard... izwe elihlukile elinesimo esihlukile...

Imininingwane eyengeziwe mayelana nezinga elijwayelekile.

Ngaphezu kokuba yisicaba, ukuphindaphinda kumele kuqinisekiswe. Ukulinganisa okuphindaphindiwe kuwukulinganisa izindawo ezisicaba zendawo. Kuwukulinganisa okuthathwa noma kuphi ebusweni bepuleti okuzophinda ngaphakathi kokubekezelelana okuchaziwe. Ukulawula ukuba yisicaba kwendawo kuya ekubekezelelaneni okuqinile kunokwesicaba jikelele kuqinisekisa ushintsho oluncane kancane kuphrofayili yokuba yisicaba ebusweni, ngaleyo ndlela kuncishiswe amaphutha endawo.

Ukuqinisekisa ukuthi ipuleti lobuso lihlangabezana kokubili nokucaciswa okuyisicaba kanye nokulinganisa okuphindaphindiwe, abakhiqizi bamapuleti obuso be-granite kufanele basebenzise i-Federal Specification GGG-P-463c njengesisekelo semininingwane yabo. Leli zinga libhekana nokunemba kokulinganisa okuphindaphindiwe, izakhiwo zezinto ze-granite lobuso, ukuqeda kobuso, indawo yokusekela, ukuqina, izindlela ezamukelekayo zokuhlola kanye nokufakwa kwezinto ezifakiwe ezinentambo.

Ukuhlola Ukunemba Kwepuleti

Ngokulandela iziqondiso ezimbalwa ezilula, ukutshalwa kwezimali epuletini lobuso be-granite kufanele kuhlale iminyaka eminingi. Kuye ngokusetshenziswa kwepuleti, indawo yesitolo kanye nokunemba okudingekayo, imvamisa yokuhlola ukunemba kwepuleti lobuso iyahlukahluka. Umthetho ojwayelekile uwukuthi ipuleti elisha lithole ukulungiswa kabusha okugcwele kungakapheli unyaka owodwa wokuthenga. Uma ipuleti lisetshenziswa njalo, kungcono ukufinyeza lesi sikhathi sibe yizinyanga eziyisithupha.

Ngaphambi kokuba ipuleti elingaphezulu liguge ngaphezu kwencazelo yokuthi libanzi kangakanani, lizobonisa izinsika ezigugile noma ezigobile. Ukuhlolwa kwanyanga zonke kwamaphutha okulinganisa okuphindaphindiwe kusetshenziswa i-gage yokufunda ephindaphindayo kuzobona izindawo zokuguguleka. I-gage yokufunda ephindaphindayo iyithuluzi elinembile kakhulu elithola iphutha lendawo futhi lingaboniswa ku-amplifier kagesi yokukhulisa okuphezulu.

Uhlelo lokuhlola olusebenzayo kufanele luhlanganise ukuhlolwa okuvamile nge-autocollimator, okuhlinzeka ngokulinganiswa kwangempela kobucaba obuphelele obungalandelelwa yi-National Institute of Standards and Technology (NIST). Ukulinganiswa okuphelele ngumkhiqizi noma inkampani ezimele kuyadingeka ngezikhathi ezithile.

Ukwehluka Phakathi Kokulinganisa

Kwezinye izimo, kukhona ukwehluka phakathi kokulinganiswa kwepuleti lobuso. Ngezinye izikhathi izici ezifana nokushintsha kobuso okubangelwa ukuguguleka, ukusetshenziswa okungalungile kwemishini yokuhlola noma ukusetshenziswa kwemishini engalinganiswanga kungabangela lokhu kwehluka. Nokho, izici ezimbili ezivame kakhulu izinga lokushisa kanye nokusekelwa.

Enye yezinto ezibaluleke kakhulu izinga lokushisa. Isibonelo, indawo engaphansi kungenzeka ukuthi igezwe ngesisombululo esishisayo noma esibandayo ngaphambi kokulinganiswa futhi ayivunyelwanga isikhathi esanele sokujwayela. Ezinye izimbangela zokushintsha kwezinga lokushisa zifaka phakathi umoya obandayo noma oshisayo, ukukhanya kwelanga okuqondile, ukukhanya okuphezulu noma eminye imithombo yokushisa okukhulu ebusweni bepuleti.

Kungaba khona futhi nokwehluka kwe-gradient yokushisa eqondile phakathi kobusika nehlobo. Kwezinye izimo, ipuleti alivunyelwe isikhathi esanele sokulungisa ngemva kokuthunyelwa. Kungumqondo omuhle ukurekhoda izinga lokushisa le-gradient eqondile ngesikhathi kwenziwa ukulinganisa.

Esinye isizathu esivamile sokwehluka kokulinganisa ipuleti elingasekelwanga kahle. Ipuleti elingaphezulu kufanele lisekelwe ezindaweni ezintathu, okungcono libe ngama-20% wobude ukusuka emaphethelweni epuleti. Izisekelo ezimbili kufanele zibe ngama-20% wobubanzi ukusuka emaceleni amade, kanti isekelo esisele kufanele sibe phakathi nendawo.

Amaphuzu amathathu kuphela angahlala ngokuqinile kunoma yini ngaphandle kwendawo enembile. Ukuzama ukusekela ipuleti ngamaphuzu angaphezu kwamathathu kuzokwenza ipuleti lithole ukwesekwa kwalo kusuka ezinhlanganisweni ezahlukene zamaphuzu amathathu, okungeke kube amaphuzu amathathu afanayo lapho lisekelwa khona ngesikhathi sokukhiqizwa. Lokhu kuzoletha amaphutha njengoba ipuleti liphambuka ukuze livumelane nelungiselelo elisha lokusekela. Cabanga ukusebenzisa izitendi zensimbi ezinemishayo yokusekela eyenzelwe ukuhambisana namaphuzu okusekela afanele. Izitendi zale njongo zivame ukutholakala kumkhiqizi wepuleti lokusekela.

Uma ipuleti lisekelwe kahle, ukulevelisha okunembile kuyadingeka kuphela uma uhlelo lokusebenza luyicacisa. Ukulevelisha akudingekile ukuze kulondolozwe ukunemba kwepuleti elisekelwe kahle.

Nweba Impilo Yepuleti

Ukulandela iziqondiso ezimbalwa kuzonciphisa ukuguguleka kwepuleti lobuso be-granite futhi ekugcineni, kwandise isikhathi salo sokuphila.

Okokuqala, kubalulekile ukugcina ipuleti lihlanzekile. Uthuli oluvuthayo oluvela emoyeni luvame ukuba umthombo omkhulu wokuguga nokuklebhuka kwepuleti, njengoba luvame ukungena ezintweni zokusebenza kanye nezindawo zokuthintana zama-gauge.

Kubalulekile futhi ukumboza amapuleti ukuze uwavikele othulini nasemonakalweni. Isikhathi sokuguguleka singandiswa ngokumboza ipuleti uma lingasetshenziswa.

Jikelezisa ipuleti njalo ukuze indawo eyodwa ingasebenzisi kakhulu. Futhi, kunconywa ukuthi kufakwe ama-carbide pad esikhundleni sama-contact pad ensimbi lapho kulinganiswa.

Gwema ukubeka ukudla noma iziphuzo ezibandayo epuletini. Iziphuzo eziningi ezibandayo ziqukethe i-carbonic noma i-phosphoric acid, engancibilikisa amaminerali athambile futhi ishiye imigodi emincane ebusweni.

Ukuphinda Ubuyele Emuva

Uma ipuleti lobuso le-granite lidinga ukufakelwa kabusha, cabanga ukuthi le nsizakalo yenziwe endaweni noma endaweni yokulinganisa. Kungcono njalo ukuthi ipuleti lifakwe kabusha efektri noma endaweni enikezelwe. Kodwa-ke, uma ipuleti lingagugi kakhulu, ngokuvamile lingaphakathi kwamasentimitha angu-0.001 okubekezelelana okudingekayo, lingafakwa kabusha endaweni. Uma ipuleti ligugiwe laze lafika ezingeni lapho lingaphezu kwamasentimitha angu-0.001 okubekezelelana, noma uma linezimbobo noma lingcolile kabi, kufanele lithunyelwe efektri ukuze ligaywe ngaphambi kokuliphinda.

Isikhungo sokulinganisa sinemishini kanye nokuhlelwa kwefektri okunikeza izimo ezifanele zokulinganisa ipuleti kahle kanye nokulungiswa kabusha uma kudingeka.

Kufanele kuqashelwe kakhulu ekukhetheni uchwepheshe wokulinganisa nokulungisa indawo. Cela ukugunyazwa bese uqinisekisa ukuthi imishini ezosetshenziswa uchwepheshe inokulinganiswa okulandelekayo. Ulwazi nalo luyisici esibalulekile, njengoba kuthatha iminyaka eminingi ukufunda ukuthi i-granite eqondile igobe kanjani ngendlela efanele.

Ukulinganisa okubalulekile kuqala ngepuleti lobuso le-granite elinembile njengesisekelo. Ngokuqinisekisa ireferensi ethembekile ngokusebenzisa ipuleti lobuso elilinganiswe kahle, abakhiqizi banelinye lamathuluzi abalulekile okulinganisa okuthembekile nezingxenye zekhwalithi engcono.Q

Uhlu Lokuhlola Lokuhlukahluka Kokulinganisa

1. Indawo engaphezulu yagezwa ngesisombululo esishisayo noma esibandayo ngaphambi kokulungiswa futhi ayinikwanga isikhathi esanele sokujwayela.

2. Ipuleti alisekelwanga kahle.

3. Ukushintsha kwezinga lokushisa.

4. Ama-draft.

5. Ukukhanya kwelanga okuqondile noma okunye ukushisa okukhanyayo ebusweni bepuleti. Qiniseka ukuthi ukukhanya okuphezulu akufudumezi ubuso.

6. Ukwehluka kwe-gradient yokushisa evundlile phakathi kobusika nehlobo. Uma kungenzeka, yazi izinga lokushisa le-gradient evundlile ngesikhathi kwenziwa ukulinganisa.

7. Ipuleti alivunyelwe isikhathi esanele sokujwayela ngemva kokuthunyelwa.

8. Ukusetshenziswa kabi kwemishini yokuhlola noma ukusetshenziswa kwemishini engalinganisiwe.

9. Ushintsho lobuso oluvela ekugugeni.

Amathiphu Obuchwepheshe

- Ngenxa yokuthi ukulinganisa ngakunye okuqondile kuncike endaweni enembile yokubhekisela lapho kuthathwa khona ubukhulu bokugcina, amapuleti obuso ahlinzeka ngendiza engcono kakhulu yokubhekisela yokuhlola umsebenzi kanye nokuhlelwa kwawo ngaphambi komshini.

- Ukulawula ukuthamba kwendawo kuze kube yilapho kubekezelelana kakhulu kunokwethamba okuphelele kuqinisekisa ushintsho oluncane kancane kuphrofayili yokuthamba kwendawo, ngaleyo ndlela kuncishiswe amaphutha endawo.

- Uhlelo lokuhlola olusebenzayo kufanele luhlanganise ukuhlolwa okuvamile nge-autocollimator, okuhlinzeka ngokulinganiswa kwangempela kokuthamba okuphelele okulandelwa yi-National Inspection Authority.

Phakathi kwezinhlayiya zamaminerali ezakha i-granite, ezingaphezu kuka-90% yi-feldspar ne-quartz, okuyi-feldspar eningi kakhulu. I-feldspar ivame ukuba mhlophe, mpunga, futhi ibomvu njengenyama, kanti i-quartz iningi layo ayinambala noma imhlophe ngwevu, okwenza umbala oyisisekelo we-granite. I-Feldspar ne-quartz zingamaminerali aqinile, futhi kunzima ukuzihambisa ngommese wensimbi. Ngokuphathelene namabala amnyama ku-granite, ikakhulukazi i-mica emnyama, kunezinye izimbiwa. Nakuba i-biotite ithambile, ikhono layo lokumelana nokucindezeleka alibuthakathaka, futhi ngesikhathi esifanayo banenani elincane ku-granite, ngokuvamile lingaphansi kuka-10%. Lesi yisimo sezinto lapho i-granite inamandla khona kakhulu.

Esinye isizathu esenza i-granite ibe namandla ukuthi izinhlayiya zayo zamaminerali zinamathelene futhi zinamathele komunye nomunye. Izikhala zivame ukuba ngaphansi kuka-1% womthamo ophelele wedwala. Lokhu kunikeza i-granite ikhono lokubekezelela ukucindezeleka okunamandla futhi ayingeni kalula umswakama.

Izingxenye zegranite zenziwe ngamatshe angenawo umhlwa, ukumelana ne-asidi kanye ne-alkali, ukumelana okuhle nokuguguleka kanye nokuphila isikhathi eside, akukho ukulungiswa okukhethekile. Izingxenye zokunemba kwegranite zisetshenziswa kakhulu ekusetshenzisweni kwamathuluzi embonini yemishini. Ngakho-ke, zibizwa ngokuthi izingxenye zokunemba kwegranite noma izingxenye zegranite. Izici zezingxenye zokunemba kwegranite ziyafana nezezinkundla zegranite. Isingeniso ekusetshenzisweni kwamathuluzi kanye nokulinganiswa kwezingxenye zokunemba kwegranite: Ubuchwepheshe bokusebenza ngokunemba kanye nobuchwepheshe bokusebenza ngomshini omncane kuyizinkomba ezibalulekile zokuthuthukiswa kwemboni yokukhiqiza imishini, futhi sezibe yinkomba ebalulekile yokulinganisa izinga lobuchwepheshe obuphezulu. Ukuthuthukiswa kobuchwepheshe obusezingeni eliphezulu kanye nomkhakha wokuzivikela akuhlukaniseki nobuchwepheshe bokusebenza ngokunemba kanye nobuchwepheshe bokusebenza ngomshini omncane. Izingxenye zegranite zingashelela kahle ekulinganisweni, ngaphandle kokuma. Ukulinganiswa kobuso bomsebenzi, imihuzuko evamile ayithinti ukunemba kokulinganisa. Izingxenye zegranite zidinga ukwakheka nokukhiqizwa ngokwezidingo zohlangothi lwesidingo.

Inkambu yesicelo:

Njengoba sonke sazi, imishini nemishini eminingi ikhetha izingxenye ze-granite ezinembile.

Izingxenye ze-granite zisetshenziselwa ukunyakaza okunamandla, ama-linear motors, i-cmm, i-cnc, umshini we-laser...

wamukelekile ukuxhumana nathi ukuze uthole ulwazi olwengeziwe.

Amadivayisi okulinganisa i-granite kanye nezingxenye ze-granite ezenziwe nge-granite emnyama yekhwalithi ephezulu. Ngenxa yokunemba kwayo okuphezulu, isikhathi eside, ukuzinza okuhle kanye nokumelana nokugqwala, ibilokhu isetshenziswa kakhulu ekuhlolweni komkhiqizo embonini yanamuhla kanye nezindawo zesayensi ezifana nesikhala se-aero se-mechanical kanye nocwaningo lwesayensi.

Izinzuzo

----Kuqine kabili kunensimbi ephonswe ngensimbi;

----Izinguquko ezincane zobukhulu zibangelwa izinguquko zokushisa;

----- Ayinankinga, ngakho-ke akukho ukuphazamiseka komsebenzi ;

---- Ayinazo izimbobo noma ama-protrusion ngenxa yesakhiwo sezinhlamvu ezincane kanye nokunamathela okungabalulekile, okuqinisekisa izinga eliphezulu lokusicaba empilweni yenkonzo ende futhi ayibangeli monakalo kwezinye izingxenye noma izinsimbi;

-----Ukusebenza okungenazinkinga kokusetshenziswa nezinto ezisebenza ngogesi;

----Impilo ende futhi ayinagqwala, okuholela ezindleleni eziphansi zokulungisa.

Amapuleti obuso be-granite aqondile ahlanganiswe ngokunemba kuze kube sezingeni eliphezulu lokusicaba ukuze kufezwe ukunemba futhi asetshenziswa njengesisekelo sokufaka izinhlelo zokulinganisa eziyinkimbinkimbi zemishini, ze-elekthronikhi kanye nezokukhanya.

Ezinye zezici eziyingqayizivele zepuleti lobuso be-granite:

Ukufana Kobulukhuni;

Izimo Ezinembile Ngaphansi Komthwalo;

Isimunca Ukudlidliza;

Kulula Ukuyihlanza;

Ukumelana nokugoqa;

Ukuvuleka Okuphansi;

Akunaziphazamiso;

Akuyona i-Magnetic

Izinzuzo zePlate Yomphezulu weGranite

Okokuqala, idwala ngemva kwesikhathi eside sokuguga kwemvelo, isakhiwo esifanayo, ubuncane be-coefficient, ukucindezeleka kwangaphakathi kuyanyamalala ngokuphelele, akuguquguquki, ngakho-ke ukunemba kuphezulu.

Okwesibili, ngeke kube khona imihuzuko, hhayi ngaphansi kwezimo zokushisa ezihlala njalo, ekushiseni kwegumbi kungagcina nokunemba kokulinganiswa kokushisa.

Okwesithathu, hhayi ukuzivumelanisa nemvelo, ukulinganisa kungaba ukunyakaza okubushelelezi, akukho mizwa yokuklwebheka, okungathinteki umswakama, indiza izinzile.

Okwesine, ukuqina kuhle, ubulukhuni buphezulu, ukumelana nokuklwebheka kunamandla.

Ezinhlanu, angesabi i-asidi, ukuguguleka koketshezi lwe-alkaline, ngeke kugqwale, akudingeki upende uwoyela, akulula ukunamathela uthuli oluncane, ukulungiswa, kulula ukugcinwa, impilo yenkonzo ende.

Kungani ukhethe isisekelo segranite esikhundleni sombhede womshini wensimbi ophonswe?

1. Isisekelo somshini we-granite singagcina ukunemba okuphezulu kunesisekelo somshini we-cast iron. Isisekelo somshini we-cast iron sithinteka kalula yizinga lokushisa kanye nomswakama kodwa isisekelo somshini we-granite ngeke sithinteke;

2. Ngosayizi ofanayo wesisekelo somshini we-granite kanye nesisekelo sensimbi ephonswe, isisekelo somshini we-granite sisebenza kahle kakhulu kunensimbi ephonswe;

3. Isisekelo somshini wegranite esikhethekile kulula ukusiqeda kunesisekelo somshini wensimbi ephonswe ngensimbi.

Amapuleti obuso begranite ayizinto ezibalulekile kumalebhu okuhlola ezweni lonke. Ubuso obulinganisiwe, obuyisicaba kakhulu bepuleti lobuso buvumela abahloli ukuthi bawasebenzise njengesisekelo sokuhlolwa kwezingxenye kanye nokulinganiswa kwezinsimbi. Ngaphandle kokuqina okunikezwa amapuleti obuso, izingxenye eziningi ezibekezelelwe kahle emikhakheni ehlukahlukene yezobuchwepheshe kanye nezokwelapha kungaba nzima kakhulu, uma kungenzeki, ukukhiqiza ngendlela efanele. Yiqiniso, ukusebenzisa ibhulokhi lobuso begranite ukulinganisa nokuhlola ezinye izinto namathuluzi, ukunemba kwegranite ngokwayo kumele kuhlolwe. Abasebenzisi bangalinganisa ipuleti lobuso begranite ukuqinisekisa ukunemba kwalo.

Hlanza ipuleti lobuso begranite ngaphambi kokulinganisa. Thela inani elincane lesihlanzi sepuleti lobuso endwangu ehlanzekile, ethambile bese usula ubuso begranite. Sula ngokushesha isihlanzi epuletini lobuso ngendwangu eyomile. Ungavumeli uketshezi lokuhlanza lome emoyeni.

Beka igeyiji yokulinganisa ephindaphindwayo phakathi kwepuleti lobuso begranite.

Faka i-zero ku-gauge yokulinganisa ephindaphindwayo ebusweni bepuleti le-granite.

Hambisa igeyiji kancane phezu kobuso begranite. Buka inkomba yegeyiji bese uqopha iziqongo zanoma yikuphi ukushintshashintsha kokuphakama njengoba uhambisa ithuluzi ngaphesheya kwepuleti.

Qhathanisa ukwehluka kokusicaba ebusweni bepuleti nokwehluka kwepuleti lakho lobuso, okuhlukahluka ngokusekelwe kusayizi wepuleti kanye nezinga lokusicaba legranite. Bheka imininingwane kahulumeni i-GGG-P-463c (bheka Izinsiza) ukuze uthole ukuthi ipuleti lakho liyahlangabezana yini nezidingo zokusicaba ngobukhulu balo kanye nezinga lalo. Ukwehluka phakathi kwephuzu eliphakeme kakhulu epuletini kanye nephuzu eliphansi kakhulu epuletini ukulinganisa kwalo ukusicaba.

Hlola ukuthi ukuhlukahluka okukhulu kakhulu kokujula ebusweni bepuleti kuwela ngaphansi kwezimiso zokuphindaphinda kwepuleti yalowo sayizi nezinga. Bheka imininingwane kahulumeni i-GGG-P-463c (bheka Izinsizakusebenza) ukuze unqume ukuthi ipuleti lakho liyahlangabezana yini nezidingo zokuphindaphinda ngobukhulu balo. Yenqaba ipuleti lobuso uma ngisho nephuzu elilodwa lihluleka izidingo zokuphindaphinda.

Yeka ukusebenzisa ipuleti lobuso le-granite elihluleka ukuhlangabezana nezidingo zikahulumeni. Buyisela ipuleti kumkhiqizi noma enkampanini yobuso be-granite ukuze ibhulokhi liphinde lipholishwe ukuze kuhlangatshezwane nezimiso.

Ithiphu

Yenza ukulinganisa okusemthethweni okungenani kanye ngonyaka, yize amapuleti ongaphezulu e-granite asetshenziswa kakhulu kufanele alinganiswe kaningi.

Ukulinganisa okusemthethweni nokuqoshwayo ezindaweni zokukhiqiza noma zokuhlola kuvame ukwenziwa ngokuqinisekiswa kwekhwalithi noma umthengisi wezinsizakalo zokulinganisa zangaphandle, yize noma ubani angasebenzisa igeyiji yokulinganisa ephindaphindwayo ukuhlola ipuleti lobuso ngokungahlelekile ngaphambi kokusebenzisa.

Umlando Wokuqala Wamapuleti Okuphezulu E-Granite

Ngaphambi kweMpi Yezwe II, Abakhiqizi basebenzisa ama-Steel Surface Plates ukuhlola izingxenye ngobukhulu. Ngesikhathi seMpi Yezwe II isidingo sensimbi sanda kakhulu, futhi ama-Steel Surface Plates amaningi ancibilikiswa. Kwakudingeka ukushintshwa, futhi i-Granite yaba yinto ekhethwayo ngenxa yezakhiwo zayo eziphakeme ze-metrological.

Izinzuzo eziningana ze-granite kunensimbi zabonakala. I-granite ilukhuni, yize ibuthakathaka kakhulu futhi ingase iqhekezwe. I-Granite ungayigoqa ibe yisicaba kakhulu futhi isheshe kunensimbi. I-Granite nayo inesici esifiselekayo sokwanda kokushisa okuphansi uma kuqhathaniswa nensimbi. Ngaphezu kwalokho, uma ipuleti lensimbi lidinga ukulungiswa, kwakudingeka likhuhlwe ngesandla ngabachwepheshile abasebenzisa amakhono abo ekwakheni kabusha amathuluzi omshini.

Njengenothi eliseceleni, amanye amapuleti ensimbi asasetshenziswa nanamuhla.

Izakhiwo Ze-Metrological Zamapuleti E-Granite

I-Granite iyidwala eliyi-igneous elakhiwe ukuqhuma kwezintaba-mlilo. Uma kuqhathaniswa, imabula iyi-limestone eguqulwe yaba yi-metromorphosed. Ukuze kusetshenziswe i-metrology, i-granite ekhethiwe kufanele ihlangabezane nezidingo ezithile ezichazwe ku-Federal Specification GGG-P-463c, kusukela manje kuqhubeke ebizwa ngokuthi i-Fed Specs, futhi ikakhulukazi, Ingxenye 3.1 3.1 Phakathi kwe-Fed Specs, i-granite kufanele ibe ukuthungwa okuncane kuya kokuphakathi.

I-granite iyinto eqinile, kodwa ubulukhuni bayo buyahlukahluka ngezizathu eziningana. Uchwepheshe wepuleti le-granite onolwazi angalinganisa ubulukhuni ngombala wayo okuyisibonakaliso sokuqukethwe kwe-quartz yayo. Ubulukhuni be-granite buyisici esichazwa ngokwengxenye ngobuningi bokuqukethwe kwe-quartz kanye nokuntuleka kwe-mica. Ama-granite abomvu napinki avame ukuba nzima kakhulu, amampunga abubunzima obuphakathi, kanti amnyama athambile kakhulu.

I-Young's Modulus of Elasticity isetshenziselwa ukuveza ukuguquguquka noma isibonakaliso sokuqina kwetshe. I-granite epinki ingama-pointi angu-3-5 esikalini, i-grey ingama-pointi angu-5-7 kanti i-black ingama-pointi angu-7-10. Uma inombolo incane, i-granite ivame ukuba nzima. Uma inombolo inkulu, i-granite ithambile futhi iguquguquka kakhudlwana. Kubalulekile ukwazi ubulukhuni be-Granite lapho ukhetha ubukhulu obudingekayo ukuze kube namazinga okubekezelelana kanye nesisindo sezingxenye nama-gauge abekwe phezu kwayo.

Ezinsukwini zakudala lapho kwakukhona ochwepheshe bemishini bangempela, abaziwa ngamabhukwana abo etafula eliyi-trig emaphaketheni ehembe labo, i-granite emnyama yayibhekwa njenge-"Engcono Kakhulu." I-Best ichazwa njengohlobo olunikeza ukumelana okukhulu kokuguguleka noma oluqinile. Inkinga eyodwa ukuthi ama-granite aqinile avame ukuqhekeka noma ukuqhekeka kalula. Ochwepheshe bemishini babeqiniseka kakhulu ukuthi i-granite emnyama iyona engcono kakhulu kangangokuthi abanye abakhiqizi be-granite epinki babeyidaya ngombala omnyama.

Mina mathupha ngibone ipuleti elehliswa ku-forklift lapho lisuswa endaweni yokugcina. Ipuleti lawela phansi lahlukana kabili lembula umbala opinki wangempela. Qaphela uma uhlela ukuthenga i-granite emnyama eShayina. Sincoma ukuthi uchithe imali yakho ngenye indlela. Ipuleti le-granite lingahluka ngokuqina kwalo. Umugqa we-quartz ungaba nzima kakhulu kunelinye ipuleti elingaphezulu. Isendlalelo se-gabbro emnyama singenza indawo ithambe kakhulu. Ochwepheshe bokulungisa ipuleti elingaphezulu abaqeqeshwe kahle nabanolwazi bayazi ukuthi bangazisingatha kanjani lezi zindawo ezithambile.

Amabanga ePlate Yomphezulu

Kunezinhlobo ezine zamapuleti obuso. Ibanga lelebhu i-AA kanye ne-A, Ibanga Lokuhlolwa Kwegumbi B, kanti elesine yiBanga Lokusebenzela. I-AA kanye ne-A zeBanga yizona ezithambile kakhulu futhi zibekezelela ukuthamba okungcono kune-0.00001 kupuleti leBanga le-AA. Amabanga Okusebenzela angamafulethi amancane futhi njengoba igama lisho, ahloselwe ukusetshenziswa emakamelweni amathuluzi. Lapho njengoba iBanga le-AA, iBanga le-A kanye neBanga le-B kuhloselwe ukusetshenziswa elabhorethri yokuhlola noma yokulawula ikhwalithi.

PUkuhlolwa kwe-roper Kokulinganiswa Kwepuleti Lomphezulu

Bengilokhu ngitshela amakhasimende ami ukuthi ngingakhipha noma yimuphi umntwana oneminyaka eyi-10 esontweni lami ngimfundise ngezinsuku ezimbalwa nje ukuthi angalihlola kanjani ipuleti. Akunzima. Kudinga amasu athile ukuze kwenziwe umsebenzi ngokushesha, amasu umuntu awafunda ngokuhamba kwesikhathi nokuphindaphinda okuningi. Kufanele ngikwazise, futhi angikwazi ukugcizelela ngokwanele, i-Fed Spec GGG-P-463c AKUYONA inqubo yokulinganisa! Okuningi ngalokho kamuva.

Ukulinganisa ukuthamba okuphelele (i-Mean Pane) kanye nokuhlolwa kokuphindaphinda (ukugqoka kwendawo) kuyinto edingekayo Ngokusho kwe-Fed Specs. Okuwukuphela komehluko kulokhu ngamapuleti amancane lapho ukuphindaphinda kudingeka khona kuphela.

Futhi, futhi okubaluleke kakhulu njengezinye izivivinyo, ukuhlolwa kwe-thermal gradients. (Bheka i-Delta T ngezansi)

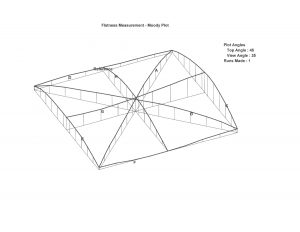

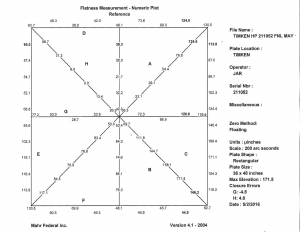

Umfanekiso 1

Ukuhlolwa kwe-Flatness kunezindlela ezi-4 ezivunyiwe. Amazinga e-elekthronikhi, i-autocollimation, i-laser kanye nedivayisi eyaziwa ngokuthi i-plane locator. Sisebenzisa amazinga e-elekthronikhi kuphela ngoba ayindlela enembile kakhulu futhi esheshayo ngezizathu eziningana.

Ama-Laser nama-autocollimator asebenzisa umsebe wokukhanya oqondile kakhulu njengereferensi. Umuntu wenza isilinganiso sokunemba kwepuleti lobuso be-granite ngokuqhathanisa umehluko webanga phakathi kwepuleti lobuso nomsebe wokukhanya. Ngokuthatha umsebe wokukhanya oqondile, uwushayele ethagethini lokubonakalisa ngenkathi uhambisa ithagethi lokubonakalisa phansi kwepuleti lokubonisa, ibanga phakathi komsebe okhishwayo nomsebe wokubuyisa liyisilinganiso sokunemba.

Nansi inkinga ngale ndlela. Inhloso kanye nomthombo kuthinteka ukudlidliza, izinga lokushisa elizungezile, inhloso engaphansi kwesicaba noma eklwebhekile, ukungcola emoyeni, kanye nokuhamba komoya (amaza). Konke lokhu kunikela ngezingxenye ezengeziwe zephutha. Ngaphezu kwalokho, umnikelo wephutha lomqhubi ngokuhlolwa nge-autocollimator mkhulu kakhulu.

Umsebenzisi we-autocollimator onolwazi angenza izilinganiso ezinembile kakhulu kodwa usabhekene nezinkinga ngokuhambisana kokufundwa ikakhulukazi emabangeni amade njengoba ukubonakaliswa kuvame ukunwebeka noma ukufiphala kancane. Futhi, ithagethi elingalingani kahle kanye nosuku olude lokubuka ngelensi kudala amaphutha engeziwe.

Idivayisi yokuthola indiza iwubuwula nje. Le divayisi isebenzisa ukukhanya okuqondile (uma kuqhathaniswa nokukhanya okuqondile kakhulu noma ukukhanya kwe-laser) njengereferensi yayo. Akukhona nje kuphela ukuthi idivayisi yomshini isebenzisa inkomba evame ukuba nesisombululo esingu-20 u Inch kuphela kodwa ukungalungi kwebha nezinto ezingafani kunezela kakhulu emaphutheni ekulinganisweni. Ngokombono wethu, yize le ndlela iyamukeleka, ayikho ilabhorethri enekhono engasebenzisa idivayisi yokuthola indiza njengethuluzi lokugcina lokuhlola.

Amazinga kagesi asebenzisa amandla adonsela phansi njengereferensi yawo. Amazinga kagesi ahlukene awathintwa ukudlidliza. Anesisombululo esiphansi njengesekhondi elingu-.1 arc futhi izilinganiso ziyashesha, zinembile futhi kuncane kakhulu umnikelo wephutha ovela kumqhubi onolwazi. Ama-Plane Locators noma ama-autocollimator awahlinzeki nge-topographical eyenziwe ngekhompyutha (Isithombe 1) noma ama-isometric plots (Isithombe 2) sobuso.

Umfanekiso 2

Ukuhlolwa Kobuso Obuqondile

Ukuqina okufanele kokuhlolwa kobuso kuyingxenye ebaluleke kakhulu yaleli phepha, bekufanele ngabe ngiyibeke ekuqaleni. Njengoba kushiwo ngaphambili, i-Fed Spec. GGG-p-463c AKUYONA indlela yokulinganisa. Isebenza njengomhlahlandlela wezici eziningi ze-granite yebanga le-metrology lapho umthengi okuhloswe ukuthi abe yinoma iyiphi i-Federal Government Agency, futhi lokho kuhlanganisa izindlela zokuhlola kanye nokubekezelelana noma amamaki. Uma unkontileka ethi unamathele ku-Fed Specs, khona-ke inani lokuqina kufanele linqunywe yi-Moody Method.

UMoody wayengumuntu wakudala kakhulu ngawo-1950 owasungula indlela yezibalo ukuze anqume ukuthi i-flat iyonke futhi acabangele ukuqondiswa kwemigqa evivinyiwe, ukuthi isondelene ngokwanele yini endaweni efanayo. Akukho okushintshile. I-Allied Signal yazama ukuthuthukisa indlela yezibalo kodwa yaphetha ngokuthi umehluko wawumncane kakhulu kangangokuthi kwakungafanele umzamo.

Uma usonkontileka wepuleti lobuso esebenzisa amazinga e-elekthronikhi noma i-laser, usebenzisa ikhompyutha ukumsiza ngokubala. Ngaphandle kosizo lwekhompyutha, uchwepheshe osebenzisa i-autocollimation kumele abale ukufundwa ngesandla. Eqinisweni, akwenzi lokho. Kuthatha isikhathi eside kakhulu futhi empeleni kungaba nzima kakhulu. Ekuhlolweni kokuba yisicaba kusetshenziswa i-Moody Method, uchwepheshe uhlola imigqa eyisishiyagalombili ekucushweni kwe-Union Jack ukuze athole ukunemba.

Indlela Yokuzizwa Ukhululekile

Indlela yeMoody iyindlela yezibalo yokunquma ukuthi imigqa eyisishiyagalombili isendizeni efanayo. Ngaphandle kwalokho, unemigqa eyisishiyagalombili eqondile engaba sendizeni efanayo noma ingabi sendizeni efanayo. Ngaphezu kwalokho, umakhi othi unamathela ku-Fed Spec, futhi usebenzisa i-autocollimation, yenakumelekhiqiza amakhasi ayisishiyagalombili edatha. Ikhasi elilodwa lomugqa ngamunye lihlolwe ukuze kuqinisekiswe ukuhlolwa kwakhe, ukulungiswa, noma kokubili. Ngaphandle kwalokho, umakhi akanalo ulwazi lokuthi liyini inani langempela lokuthamba.

Ngiyaqiniseka ukuthi uma ungomunye walabo abalungisa amapuleti akho ngumakhi osebenzisa i-autocollimation, awukaze uwabone lawo makhasi! Umfanekiso 3 uyisibonelo salokhueyodwa njeikhasi lesishiyagalombili elidingekayo ukuze kubalwe ukuthamba okuphelele. Esinye isibonakaliso salokho kungazi kanye nobubi ukuthi umbiko wakho unezinombolo ezinhle ezizungezwe. Isibonelo, 200, 400, 650, njll. Inani elibalwe kahle yinombolo yangempela. Isibonelo 325.4 u In. Uma usonkontileka esebenzisa iMoody Method yokubala, futhi uchwepheshe ebala amanani ngesandla, kufanele uthole amakhasi ayisishiyagalombili okubala kanye nesithombe se-isometric. Isithombe se-isometric sibonisa ukuphakama okuhlukahlukene emigqeni ehlukene nokuthi ibanga elingakanani elihlukanisa amaphuzu akhethiwe ahlanganayo.

Umfanekiso 3(Kuthatha amakhasi ayisishiyagalombili anjengalawa ukubala ukuba yisicaba ngesandla. Qiniseka ukuthi ubuza ukuthi kungani ungakutholi lokhu uma umakhi wakho esebenzisa i-autocollimation!)

Umfanekiso 4

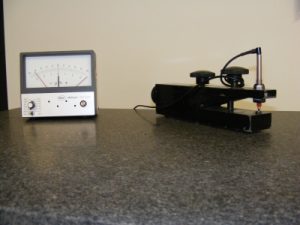

Ochwepheshe beDimensional Gauge basebenzisa amazinga okuhlukanisa (Isithombe 4) njengamadivayisi akhethwayo ukukala izinguquko zemizuzu ku-angularity kusuka esiteshini sokulinganisa kuya esiteshini. Amazinga anesisombululo esifinyelela kumasekhondi angu-.1 arc (amasentimitha angu-5 usebenzisa isileyidi esingu-4″) azinzile kakhulu, awathinteki ukudlidliza, amabanga alinganisiwe, imisinga yomoya, ukukhathala komqhubi, ukungcola komoya noma yiziphi izinkinga ezikhona kwamanye amadivayisi. Engeza usizo lwekhompyutha, futhi umsebenzi uba ngokushesha okukhulu, ukhiqize ama-topographical kanye ne-isometric plots afakazela ukuqinisekiswa futhi okubaluleke kakhulu ukulungiswa.

Ukuhlolwa Okufanelekile Kokuphindeka

Ukufunda okuphindaphindiwe noma ukuphindaphindwa yilona vivinyo elibaluleke kakhulu. Imishini esiyisebenzisayo ukwenza ukuhlolwa kokuphindaphinda iyithuluzi lokufunda okuphindaphindiwe, i-LVDT kanye ne-amplifier edingekayo ekufundeni okunesinqumo esiphezulu. Sibeka i-amplifier ye-LVDT kusisombululo esincane sama-intshi ayi-10 noma ama-intshi ayi-5 ukuze kube namapuleti anokunemba okuphezulu.

Ukusebenzisa inkomba yomshini enesisombululo sama-intshi angu-20 kuphela akusizi ngalutho uma uzama ukuhlola isidingo sokuphindaphinda sama-intshi angu-35. Izinkomba zinokungaqiniseki kwama-intshi angu-40! Ukusethwa kokufunda okuphindaphindayo kulingisa ukucushwa kwesilinganiso sokuphakama/ingxenye.

Ukuphindaphinda AKUFANI nokuba yisicaba okuphelele (i-Mean Plane). Ngithanda ukucabanga ngokuphindaphinda kwe-granite okubhekwa njengokulinganisa okulinganayo kwe-radius.

Umfanekiso 5

Uma uhlola ukuthi ibhola eliyindilinga lingaphindeka yini, uzobe usubonisile ukuthi i-radius yebhola ayishintshile. (Iphrofayili efanele yepuleti elilungisiwe kahle inomumo onomqhele oqondile.) Kodwa-ke, kusobala ukuthi ibhola alisicaba. Nokho, ngandlela thile. Ebangeni elifushane kakhulu, liyisicaba. Njengoba iningi lomsebenzi wokuhlola lihilela igeyiji yokuphakama eduze kakhulu nengxenye, ukuphindaphindwa kuba yisici esibaluleke kakhulu sepuleti le-granite. Kubaluleke kakhulu ukuthi lisicaba ngokuphelele ngaphandle kokuthi umsebenzisi ahlole ukuqondeka kwengxenye ende.

Qiniseka ukuthi umakhi wakho wenza ukuhlolwa kokufunda okuphindaphindiwe. Ipuleti lingaba nokufundwa okuphindaphindiwe kakhulu ngenxa yokubekezelela kodwa liqhubeke nokuhlolwa kokuqina! Ngokumangalisayo, ilabhorethri ingathola ukugunyazwa ekuhlolweni okungahlanganisi ukuhlolwa kokufunda okuphindaphindiwe. Ilabhorethri engakwazi ukulungisa noma engemuhle kahle ekulungiseni ikhetha ukwenza ukuhlolwa kokuqina kuphela. Ukungaguquguquki akuvamile ukushintsha ngaphandle kokuthi uhambise ipuleti.

Ukuhlolwa kokufunda okuphindaphindiwe kulula kakhulu ukukuhlola kodwa kunzima kakhulu ukukufeza uma ubhala phansi. Qiniseka ukuthi umakhi wakho angabuyisela ukuphindeka ngaphandle "kokusula" indawo noma ukushiya amagagasi ebusweni.

Ukuhlolwa kwe-Delta T

Lokhu kuhlolwa kuhilela ukulinganisa izinga lokushisa langempela letshe ebusweni balo obuphezulu kanye nobuso balo obuphansi bese kubalwa umehluko, i-Delta T, ukuze kubikwe ngesitifiketi.

Kubalulekile ukwazi ukuthi isilinganiso esimaphakathi sokwanda kokushisa ku-granite singu-3.5 uIn/Inch/degree. Umphumela wokushisa okuzungezile kanye nomswakama epuletini le-granite awubalulekile. Kodwa-ke, ipuleti elingaphezulu lingaphelelwa ukubekezelelana noma ngezinye izikhathi lithuthuke ngisho noma lise-.3 – .5 degrees F Delta T. Kubalulekile ukwazi ukuthi i-Delta T ingaphakathi kwama-.12 degrees F lapho umehluko uvela khona ekulinganisweni kokugcina.

Kubalulekile futhi ukwazi ukuthi indawo yokusebenza kwamapuleti iyafuduka iye ekushiseni. Uma izinga lokushisa eliphezulu lifudumele kunephansi, khona-ke indawo ephezulu iyakhuphuka. Uma izinga lokushisa eliphansi lifudumele, okuyinto engavamile, khona-ke indawo ephezulu iyacwila. Akwanele ngomphathi wekhwalithi noma uchwepheshe ukwazi ukuthi ipuleti liyisicaba futhi lingaphindeka ngesikhathi sokulinganisa noma sokulungisa kodwa lokho okuyiDelta T ngesikhathi sokuhlolwa kokugcina kokulinganisa. Ezimweni ezibucayi umsebenzisi angakwazi, ngokulinganisa iDelta T ngokwakhe, ukuthola ukuthi ipuleti alisakwazi yini ukubekezelela ngenxa yokushintshashintsha kweDelta T. Ngenhlanhla, i-granite ithatha amahora amaningi noma ngisho nezinsuku ukuze ivumelane nendawo. Ukushintshashintsha okuncane kwezinga lokushisa elizungezile usuku lonke ngeke kuyilimaze. Ngenxa yalezi zizathu, asibiki izinga lokushisa elizungezile noma umswakama ngoba imiphumela ayibalulekile.

Ukugqokwa Kwepuleti Legranite

Nakuba i-granite ilukhuni kunezingcwecwe zensimbi, i-granite isakha amabala aphansi ebusweni. Ukunyakaza okuphindaphindiwe kwezingxenye kanye nama-gage epuletini lobuso kungumthombo omkhulu wokuguga, ikakhulukazi uma indawo efanayo isetshenziswa njalo. Ukungcola kanye nothuli lokugaya oluvunyelwe ukuhlala ebusweni bepuleti kusheshisa inqubo yokuguga njengoba ingena phakathi kwezingxenye noma ama-gauge kanye nobuso be-granite. Lapho uhambisa izingxenye kanye nama-gage ebusweni balo, uthuli oluqothulayo luvame ukuba yimbangela yokuguga okwengeziwe. Ngincoma kakhulu ukuhlanza njalo ukuze kuncishiswe ukuguguleka. Sibonile ukuguguleka kwamapuleti okubangelwa ukulethwa kwephakheji ye-UPS nsuku zonke okubekwa phezu kwamapuleti! Lezo zindawo zokuguga ezisendaweni zithinta ukufundwa kokuhlolwa kokuphindaphinda kokulinganisa. Gwema ukuguguleka ngokuhlanza njalo.

Ukuhlanzwa Kwepuleti Legranite

Ukuze ugcine ipuleti lihlanzekile, sebenzisa indwangu yokugoqa ukuze ususe ukungcola. Cindezela kancane kakhulu, ukuze ungashiyi izinsalela zeglue. Indwangu yokugoqa esetshenziswe kahle yenza umsebenzi omuhle kakhulu wokuqoqa uthuli lokugaya phakathi kokuhlanza. Ungasebenzi endaweni efanayo. Hambisa isethaphu sakho nxazonke kwepuleti, usabalalise ukuguguleka. Kulungile ukusebenzisa utshwala ukuhlanza ipuleti, kodwa qaphela ukuthi ukwenza kanjalo kuzopholisa indawo okwesikhashana. Amanzi anensipho encane angcono kakhulu. Izihlanzi ezitholakala kwezentengiselwano njenge-Starrett's cleaner nazo zinhle kakhulu ukuzisebenzisa, kodwa qiniseka ukuthi ususa zonke izinsalela zensipho ebusweni.

Ukulungiswa Kwepuleti Legranite

Kufanele kube sobala manje ukubaluleka kokuqinisekisa ukuthi umakhi we-surface plate yakho wenza ukulinganisa okunekhono. Amalebhu ohlobo lwe-“Clearing House” anikeza izinhlelo ze-“Do it all with one call” awavamile ukuba nochwepheshe ongakwazi ukulungisa. Ngisho noma enikeza ukulungisa, awahlali enochwepheshe onolwazi oludingekayo lapho i-surface plate ingasakwazi ukubekezelela.

Uma utshelwa ukuthi ipuleti alikwazi ukulungiswa ngenxa yokuguga okukhulu, sishayele ucingo. Cishe singakwazi ukulungisa.

Ochwepheshe bethu basebenza unyaka owodwa kuya kowodwa nesigamu ngaphansi kochwepheshe we-Master Surface Plate. Sichaza uchwepheshe we-Master Surface Plate njengomuntu oqede ukuqeqeshwa kwakhe futhi onolwazi lweminyaka engaphezu kweyishumi ekulinganisweni nasekulungisweni kwe-Surface Plate. Thina kwa-Dimensional Gauge sinabasebenzi abathathu abangochwepheshe abanolwazi lweminyaka engaphezu kwengu-60. Omunye wochwepheshe bethu oyinhloko uyatholakala ngaso sonke isikhathi ukuze asisekele futhi asiqondise lapho kuvela izimo ezinzima. Bonke ochwepheshe bethu banolwazi ekulinganisweni kwe-surface plate yabo bonke osayizi, kusukela kokuncane kuya kokukhulu kakhulu, izimo zemvelo ezahlukahlukene, izimboni ezahlukene, kanye nezinkinga ezinkulu zokuguguleka.

Ama-Fed Specs anesidingo esithile sokuqeda esingu-16 kuya ku-64 Average Arithmetic Roughness (AA). Sithanda ukuqeda okuphakathi kuka-30-35 AA. Kunokuqina okwanele ukuqinisekisa ukuthi izingxenye namageji zihamba kahle futhi azinamatheli noma azisonti epuletini elingaphezulu.

Uma silungisa sihlola ipuleti ukuthi lifakwe kahle futhi lisezingeni elifanele. Sisebenzisa indlela yokugoqa eyomile, kodwa uma kwenzeka ukuguguleka okukhulu okudinga ukususwa okukhulu kwe-granite, simanzisa i-lap. Ochwepheshe bethu bayazihlanza, ziphelele, ziyashesha futhi zinembile. Lokho kubalulekile ngoba izindleko zesevisi yepuleti le-granite zihlanganisa isikhathi sakho sokuphumula kanye nomkhiqizo olahlekile. Ukulungiswa okunekhono kubaluleke kakhulu, futhi akufanele ukhethe umakhi ngentengo noma ukulula. Eminye imisebenzi yokulinganisa idinga abantu abaqeqeshwe kakhulu. Sinalokho.

Imibiko Yokugcina Yokulinganisa

Ngokulungiswa nokulinganiswa ngakunye kwepuleti lobuso, sinikeza imibiko yobuchwepheshe enemininingwane. Imibiko yethu iqukethe inani elikhulu lolwazi olubucayi nolufanele. I-Fed Spec. idinga iningi lolwazi esilunikezile. Ngaphandle kwalolo oluqukethwe kwezinye izindinganiso zekhwalithi njenge-ISO/IEC-17025, i-Fed encane kakhulu. Imininingwane yemibiko yile:

- Usayizi ku-Ft. (X' x X')

- Umbala

- Isitayela (Akubhekisele kuma-clamp ledges noma ama-ledges amabili noma amane)

- I-Modulus Elinganiselwe Yokuqina

- Ukubekezelelana Okumaphakathi Kwendiza (Kunqunywa Yibanga/Usayizi)

- Ukuphinda ukufunda Ukubekezelela (Kunqunywa ubude obuvundlile ngamasentimitha)

- Indiza Ephakathi Njengoba Itholakale

- Indiza Ephakathi njengakwesobunxele

- Phinda ukufunda njengoba kutholakale

- Phinda ukufunda njengoba kushiywe

- I-Delta T (Umehluko wokushisa phakathi kobuso obuphezulu nobaphansi)

Uma uchwepheshe edinga ukwenza umsebenzi wokuhlanganisa noma ukulungisa ipuleti elingaphezulu, khona-ke isitifiketi sokulinganisa sihambisana nesithombe sendawo noma se-isometric ukufakazela ukulungiswa okusebenzayo.

Izwi Mayelana Nokugunyazwa kwe-ISO/IEC-17025 kanye namalebhu anazo

Ukuthi nje ilabhorethri inemvume yokulinganisa ipuleti elingaphezulu akusho ukuthi iyazi ukuthi yenzani ingasaphathwa eyokukwenza ngendlela efanele! Futhi akusho ukuthi ilabhorethri ingalungisa. Izinhlangano ezigunyazayo azihlukanisi phakathi kokuqinisekisa noma ukulungisa.Afuthi ngiyazi eyodwa, mhlawumbe2ukugunyaza izinhlangano ezizokwenzaLithayiAiribhoni izungeze inja yami uma ngiyikhokhele imali eyanele! Kuyiqiniso elidabukisayo. Ngibone amalabhorethri ethola ukugunyazwa ngokwenza okukodwa kuphela kwezivivinyo ezintathu ezidingekayo. Ngaphezu kwalokho, ngibone amalabhorethri ethola ukugunyazwa ngokungaqiniseki okungenangqondo futhi ethola ukugunyazwa ngaphandle kobufakazi noma ukuboniswa ukuthi babala kanjani amanani. Konke kuyishwa.

Ukuhlanganiswa

Awukwazi ukuyithatha kancane indima yamapuleti e-granite anembile. Ireferensi eyisicaba enikezwa amapuleti e-granite iyisisekelo lapho wenza khona zonke ezinye izilinganiso.

Ungasebenzisa amathuluzi okulinganisa esimanje kakhulu, anembe kakhulu futhi aguquguqukayo kakhulu. Kodwa-ke, ukulinganisa okunembile kunzima ukuqinisekisa ukuthi indawo ebhekiselwe kuyo ayithambekile. Ngesinye isikhathi, ngatshelwa ikhasimende elingase libe khona ukuthi “kulungile nje!” Impendulo yami yathi, “Kulungile, uqinisile, futhi awunakuthethelela ukuthi ochwepheshe beze ukuzolungisa amapuleti akho obuso.”

Intengo ayisona neze isizathu esihle sokukhetha osonkontileka be-surface plate. Abathengi, ababhali bezimali kanye nenani eliphazamisayo lonjiniyela bekhwalithi abaqondi njalo ukuthi ukuvuselela amapuleti e-granite akufani nokuvuselela i-micrometer, i-caliper noma i-DMM.

Amanye amathuluzi adinga ubuchwepheshe, hhayi intengo ephansi. Ngemva kokusho lokho, amanani ethu anengqondo kakhulu. Ikakhulukazi ukuze sibe nokuqiniseka ukuthi senza umsebenzi ngendlela efanele. Sidlula kakhulu izidingo ze-ISO-17025 kanye ne-Federal Specifications ngenani elengeziwe.

Amapuleti obuso ayisisekelo sokulinganisa ubukhulu obuhlukahlukene, futhi ukunakekela kahle ipuleti lakho lobuso kuyadingeka ukuqinisekisa ukunemba kokulinganisa.

I-Granite iyinto ethandwa kakhulu esetshenziselwa amapuleti angaphezulu ngenxa yezici zayo zomzimba ezifanele, njengobulukhuni bomphezulu kanye nokuzwela okuphansi kokushintshashintsha kwezinga lokushisa. Kodwa-ke, uma isetshenziswa njalo amapuleti angaphezulu abhekana nokuguguleka.

Ukuthamba kanye nokuphindaphinda kokubili kuyizinto ezibalulekile ekunqumeni ukuthi ipuleti linikeza indawo eqondile yokuthola izilinganiso ezinembile noma cha. Ukubekezelelana kwalezi zici zombili kuchazwa ngaphansi kwe-Federal Specification GGG-P-463C, DIN, GB, JJS... Ukuthamba ukulinganisa ibanga phakathi kwephuzu eliphakeme kakhulu (uphahla) kanye nephuzu eliphansi kakhulu (uphahla oluyisisekelo) epuletini. Ukuphindaphindeka kunquma ukuthi isilinganiso esithathwe endaweni eyodwa singaphindwa kulo lonke ipuleti ngaphakathi kokubekezelelana okuchaziwe. Lokhu kuqinisekisa ukuthi azikho iziqongo noma izigodi epuletini. Uma ukufundwa kungekho ngaphakathi kweziqondiso ezichaziwe, khona-ke ukuphinda kufakwe umphezulu kungadingeka ukuze kubuyiselwe izilinganiso ekucacisweni.

Ukulinganiswa kwepuleti lobuso njalo kuyadingeka ukuqinisekisa ukuthi liyisicaba futhi liyaphindaphindeka ngokuhamba kwesikhathi. Iqembu lokulinganisa ngokunemba eCross liqinisekiswe yi-ISO 17025 ngokulinganisa ukuyisicaba kanye nokuphindaphindeka kwepuleti lobuso. Sisebenzisa i-Mahr Surface Plate Certification System equkethe:

- Ukuhlaziywa kwe-Moody kanye nephrofayili,

- Ama-Isometric noma ama-Numeric plots,

- Isilinganiso Sokugijima Okuningi, kanye

- Ukuhlolwa Okuzenzakalelayo Ngokwezindinganiso Zemboni.

Imodeli Yokusiza Ngekhompyutha i-Mahr inquma noma yikuphi ukuphambuka kwe-angular noma okuqondile kusuka ezingeni eliphelele, futhi ifaneleka kahle ekufakweni kwephrofayili okunembile kakhulu kwamapuleti angaphezulu.

Izikhawu phakathi kokulinganiswa zizohluka kuye ngokuthi ukusetshenziswa kangaki, izimo zemvelo lapho ipuleti likhona, kanye nezidingo ezithile zekhwalithi yenkampani yakho. Ukugcina ipuleti lakho elingaphezulu kahle kungavumela izikhawu ezinde phakathi kokulinganiswa ngakunye, kukusiza ugweme izindleko ezengeziwe zokuphinda uhlanganiswe, futhi okubaluleke kakhulu kuqinisekisa ukuthi izilinganiso ozitholayo epuletini zinembile ngangokunokwenzeka. Nakuba amapuleti angaphezulu ebonakala eqinile, ayizinto zokunemba futhi kufanele aphathwe kanjalo. Nazi ezinye izinto okufanele uzicabangele mayelana nokunakekelwa kwamapuleti akho angaphezulu:

- Gcina ipuleti lihlanzekile, futhi uma kungenzeka ulimboze uma lingasetshenziswa

- Akukho lutho okufanele lubekwe epuletini ngaphandle kwama-gages noma izingcezu ezizolinganiswa.

- Ungasebenzisi indawo efanayo epuletini njalo.

- Uma kungenzeka, shintsha ipuleti ngezikhathi ezithile.

- Hlonipha umkhawulo womthwalo wepuleti lakho

Isisekelo se-Precision Granite Singathuthukisa Ukusebenza Kwamathuluzi Omshini

Izidingo ziyanda njalo kubunjiniyela bemishini ngokujwayelekile kanye nokwakhiwa kwamathuluzi omshini ikakhulukazi. Ukufinyelela amanani okunemba okuphezulu kanye nokusebenza ngaphandle kokukhulisa izindleko kuyinselele eqhubekayo yokuncintisana. Umbhede wamathuluzi omshini uyisici esibalulekile lapha. Ngakho-ke, abakhiqizi bamathuluzi omshini abaningi ngokwengeziwe bathembele ku-granite. Ngenxa yemingcele yayo ebonakalayo, inikeza izinzuzo ezicacile ezingenakufezwa ngensimbi noma ukhonkolo we-polymer.

I-Granite iyidwala elijulile elibizwa ngokuthi i-volcanic futhi inesakhiwo esiminyene kakhulu nesifanayo esine-coefficient ephansi kakhulu yokwanda, i-conductivity ephansi yokushisa kanye ne-damping ephezulu yokudlidliza.

Ngezansi uzothola ukuthi kungani umbono ovamile wokuthi i-granite ifaneleka kakhulu njengesisekelo somshini wemishini yokulinganisa ephezulu isiphelelwe yisikhathi futhi kungani le nto yemvelo njengesisekelo samathuluzi omshini iyindlela engcono kakhulu esikhundleni sensimbi noma insimbi ephonswe ngisho nangamathuluzi omshini anembe kakhulu.

Singakhiqiza izingxenye zegranite zokunyakaza okunamandla, izingxenye zegranite zama-linear motors, izingxenye zegranite ze-ndt, izingxenye zegranite ze-xray, izingxenye zegranite ze-cmm, izingxenye zegranite ze-cnc, ukunemba kwegranite kwe-laser, izingxenye zegranite zezindiza, izingxenye zegranite zezigaba zokunemba...

Inani Eliphezulu Elingeziwe Ngaphandle Kwezindleko Ezengeziwe

Ukusetshenziswa okwandayo kwe-granite kwezobunjiniyela bemishini akubangelwa kakhulu ukwanda okukhulu kwentengo yensimbi. Kunalokho, kungenxa yokuthi inani elengeziwe lethuluzi lomshini elitholakala ngombhede womshini owenziwe nge-granite lingenzeka ngezindleko ezincane kakhulu noma ngaphandle kwezindleko ezengeziwe. Lokhu kufakazelwa ukuqhathaniswa kwezindleko kwabakhiqizi bamathuluzi omshini abaziwayo eJalimane naseYurophu.

Inzuzo enkulu ekuzinzeni kwe-thermodynamic, ukudambisa ukudlidliza kanye nokunemba kwesikhathi eside okwenziwe yi-granite akukwazi ukufezwa ngombhede wensimbi noma wensimbi, noma ngezindleko eziphakeme kakhulu. Isibonelo, amaphutha okushisa angabalelwa ku-75% wephutha eliphelele lomshini, kanti isinxephezelo esivame ukuzama ukwenziwa yisoftware - ngempumelelo emaphakathi. Ngenxa yokuqhuba kwayo ukushisa okuphansi, i-granite iyisisekelo esingcono sokunemba kwesikhathi eside.

Njengoba ikwazi ukumelana no-1 μm, i-granite ihlangabezana kalula nezidingo zokuba yisicaba ngokusho kwe-DIN 876 ngezinga lokunemba 00. Njengoba inenani lika-6 esikalini sobunzima kusukela ku-1 kuya ku-10, iqine kakhulu, futhi ngesisindo sayo esithile esingu-2.8g/cm³ cishe ifinyelela inani le-aluminium. Lokhu kuphumela ezinzuzweni ezengeziwe ezifana namazinga aphezulu okuphakelayo, ukusheshisa okuphezulu kwe-axis kanye nokwandiswa kokuphila kwamathuluzi okusika amathuluzi omshini. Ngakho-ke, ushintsho kusuka embhedeni ophonswe ngensimbi kuya embhedeni womshini we-granite luhambisa ithuluzi lomshini okukhulunywa ngalo liye esigabeni esiphezulu ngokwezinga lokunemba nokusebenza - ngaphandle kwezindleko ezengeziwe.

Isisekelo Esithuthukisiwe Semvelo SeGranite

Ngokungafani nezinto ezifana nensimbi noma insimbi ephonswe, itshe lemvelo akudingeki likhiqizwe ngamandla amaningi nokusebenzisa izithasiselo. Kudingeka amandla amancane kuphela ekugubheni nasekuphatheni indawo. Lokhu kuphumela endaweni enhle kakhulu, ngisho nasekupheleni kokuphila komshini edlula eyensimbi njengento. Umbhede wegranite ungaba yisisekelo somshini omusha noma usetshenziswe ngezinjongo ezihluke ngokuphelele njengokusikwa kokwakhiwa komgwaqo.

Futhi akukho ukushoda kwezinsizakusebenza ze-granite. Liyidwala elijulile elakhiwe nge-magma ngaphakathi kongqimba lomhlaba. 'Likhule' izigidi zeminyaka futhi litholakala ngobuningi obukhulu njengomthombo wemvelo cishe kuwo wonke amazwekazi, kufaka phakathi lonke elaseYurophu.

Isiphetho: Izinzuzo eziningi ezibonakalayo ze-granite uma kuqhathaniswa nensimbi noma insimbi ephonswe ziqinisekisa ukuzimisela okwandayo konjiniyela bemishini ukusebenzisa le nto yemvelo njengesisekelo samathuluzi omshini asebenza kahle kakhulu futhi anembile. Ulwazi oluningiliziwe mayelana nezakhiwo ze-granite, ezizuzisa amathuluzi omshini kanye nobunjiniyela bemishini, lungatholakala kulesi sihloko esengeziwe.

Ukulinganisa okuphindaphindiwe kuwukulinganisa izindawo ezisicaba zendawo. Incazelo Yokulinganisa Okuphindaphindiwe ithi ukulinganisa okuthathwa noma kuphi ebusweni bepuleti kuzophinda ngaphakathi kokubekezelelana okuchaziwe. Ukulawula ukusicaba kwendawo yendawo kuqine kunobubanzi obuphelele kuqinisekisa ushintsho oluncane kancane kuphrofayili yokusicaba kwendawo ngaleyo ndlela kuncishiswe amaphutha endawo.

Iningi labakhiqizi, okuhlanganisa nemikhiqizo engenisiwe, banamathela ku-Federal Specification of whole flatness tolerances kodwa abaningi bayayishaya indiva izilinganiso eziphindaphindwayo. Amaningi amapuleti anenani eliphansi noma ashibhile atholakala emakethe namuhla ngeke aqinisekise izilinganiso eziphindaphindwayo. Umenzi ongaqinisekisi izilinganiso eziphindaphindwayo AKAKHIPHI amapuleti ahlangabezana nezidingo ze-ASME B89.3.7-2013 noma i-Federal Specification GGG-P-463c, noma i-DIN 876, GB, JJS...

Kokubili kubalulekile ukuqinisekisa indawo enembile ukuze kulinganiswe kahle. Ukucaciswa kobuthambeka kukodwa akwanele ukuqinisekisa ukunemba kokulinganisa. Thatha njengesibonelo, ipuleti lobuso elingu-36 X 48 Inspection Grade A, elihlangabezana kuphela nokucaciswa kobuthambeka okungu-.000300". Uma ingxenye ehlolwayo ihlanganisa iziqongo eziningana, futhi igeji esetshenziswayo isendaweni ephansi, iphutha lokulinganisa kungaba ukubekezelelana okugcwele endaweni eyodwa, okungu-000300". Empeleni, kungaba phezulu kakhulu uma igeji iphumule emthambekeni womthambe.

Amaphutha angu-.000600"-.000800" angenzeka, kuye ngokuthi uthambeke kangakanani, kanye nobude bengalo yegeji esetshenziswayo. Uma leli plate linencazelo yoKulinganisa Okuphindaphindayo engu-.000050"FIR khona-ke iphutha lokulinganisa beliyoba ngaphansi kuka-.000050" kungakhathaliseki ukuthi isilinganiso sithathwa kuphi eplateni. Enye inkinga, evame ukuvela lapho uchwepheshe ongaqeqeshiwe ezama ukuphinda afake iplate endaweni, ukusebenzisa i-Repeat Measurements kuphela ukuqinisekisa iplate.

Amathuluzi asetshenziswa ukuqinisekisa ukuphindaphindwa AZIKHETHELWANGELE ukuhlola ukuthamba okuphelele. Uma kusethwe ku-zero endaweni egobile ngokuphelele, azoqhubeka nokufunda u-zero, kungakhathaliseki ukuthi leyo ndawo ithamba ngokuphelele noma igobile ngokuphelele noma i-convex 1/2"! Amane nje aqinisekisa ukufana kwendawo, hhayi ukuthamba. Ipuleti kuphela elihlangabezana nencazelo yokuthamba KANYE nencazelo yokulinganisa okuphindaphindiwe elihlangabezana ngempela nezidingo ze-ASME B89.3.7-2013 noma i-Federal Specification GGG-P-463c.

Ask us about or flatness specification and repeat measurement promise by calling +86 19969991659 or emailing INFO@ZHHIMG.COM

Yebo, kodwa zingaqinisekiswa kuphela nge-gradient ethile yokushisa eqondile. Imiphumela yokwanda kokushisa epuletini ingabangela kalula ushintsho ekunembeni okukhulu kunokubekezelelana uma kukhona ushintsho ku-gradient. Kwezinye izimo, uma ukubekezelelana kuqinile ngokwanele, ukushisa okumuncwa ekukhanyeni okuphezulu kungabangela ushintsho olwanele lwe-gradient emahoreni amaningana.

I-Granite ine-coefficient yokwanda kokushisa okungaba ngu-.0000035 amayintshi nge-intshi ngayinye nge-1°F. Isibonelo: Ipuleti elingaphezulu elingu-36" x 48" x 8" linokunemba okungu-.000075" (1/2 yeBanga AA) ku-gradient engu-0°F, phezulu nangaphansi kuyizinga lokushisa elifanayo. Uma ingxenye ephezulu yepuleti ifudumala kuze kufike lapho ifudumele khona ngo-1°F kunephansi, ukunemba kuzoshintsha kube yi-.000275" convex! Ngakho-ke, uku-oda ipuleti elinokumelana okuqinile kuneLaboratory Grade AA kufanele kucatshangelwe kuphela uma kukhona ukulawula okwanele kwesimo sezulu.

Ipuleti elingaphezulu kufanele lisekelwe ngamaphuzu amathathu, okungcono libe ngama-20% wobude ukusuka emaphethelweni epuleti. Izisekelo ezimbili kufanele zibe ngama-20% wobubanzi ukusuka ezinhlangothini ezinde, kanti isekelo esisele kufanele sibe phakathi nendawo. Amaphuzu amathathu kuphela angahlala ngokuqinile kunoma yini ngaphandle kwendawo eqondile.

Ipuleti kufanele lisekelwe kulezi zindawo ngesikhathi sokukhiqiza, futhi kufanele lisekelwe kuphela kulezi zindawo ezintathu ngenkathi lisetshenziswa. Ukuzama ukusekela ipuleti ezindaweni ezingaphezu kwezintathu kuzokwenza ipuleti lithole ukwesekwa kwalo kusuka ezinhlanganisweni ezahlukene zamaphuzu amathathu, okungeke kube amaphuzu amathathu afanayo lapho lisekelwe khona ngesikhathi sokukhiqiza. Lokhu kuzoletha amaphutha njengoba ipuleti liphambuka ukuze livumelane nohlelo olusha lokusekela. Zonke izitendi zensimbi ze-zhhimg zinemishayo yokusekela eyenzelwe ukuhambisana namaphuzu okusekela afanele.

Uma ipuleti lisekelwe kahle, ukulevelisha okunembile kuyadingeka kuphela uma isicelo sakho sidinga lokho. Ukulevelisha akudingekile ukuze kulondolozwe ukunemba kwepuleti elisekelwe kahle.

Kungani Ukhetha I-Granite Ye-Granite?Izisekelo ZomshinifuthiIzingxenye ze-Metrology?

Impendulo ithi 'yebo' cishe kuzo zonke izinhlelo zokusebenza. Izinzuzo zegranite zifaka: Akukho ukugqwala noma ukugqwala, cishe akukwazi ukugoba, akukho ukugoba okukhokhelayo uma kukhiyiwe, isikhathi eside sokuguga, isenzo esibushelelezi, ukunemba okukhulu, cishe akusebenzi kumagnetic, ukusebenza kahle okuncane kokukhulisa ukushisa, kanye nezindleko eziphansi zokulungisa.

I-Granite uhlobo lwedwala eliyi-igneous elimbiwe ngenxa yamandla alo amakhulu, ubuningi, ukuqina, kanye nokumelana nokugqwala. Kodwa i-granite nayo inezinto eziningi kakhulu – ayigcini nje ngezikwele nezingxande! Eqinisweni, i-Starrett Tru-Stone isebenza ngokuqiniseka ngezingxenye ze-granite ezakhiwe ngezimo, ama-engeli, nama-curve azo zonke izinhlobo njalo—ngemiphumela emihle kakhulu.

Ngokusebenzisa ukucubungula kwethu okusezingeni eliphezulu, izindawo ezisikiwe zingaba yisicaba kakhulu. Lezi zimfanelo zenza i-granite ibe yinto efanelekile yokwakha izisekelo zomshini zosayizi owenziwe ngokwezifiso kanye nomklamo owenziwe ngokwezifiso kanye nezingxenye ze-metrology. I-Granite yile:

okungenziwa ngomshini

isicaba kahle uma isikiwe futhi isiqediwe

ukumelana nokugqwala

okuhlala isikhathi eside

okuhlala isikhathi eside

Izingxenye zegranite nazo kulula ukuzihlanza. Uma udala imiklamo eyenziwe ngokwezifiso, qiniseka ukuthi ukhetha igranite ngenxa yezinzuzo zayo ezinhle kakhulu.

AMAZINGA/ IZINTO EZISETSHENZISWAYO ZOKUGQOKA OKUPHEZULU

I-granite esetshenziswa yi-ZhongHui emikhiqizweni yethu ejwayelekile yepuleti lobuso inokuqukethwe okuphezulu kwe-quartz, okunikeza ukumelana okukhulu nokuguguleka nokonakala. Imibala yethu Emnyama Kakhulu kanye ne-Crystal Pink inezinga eliphansi lokumuncwa kwamanzi, okunciphisa amathuba okugqwala kokunemba kwakho ngenkathi ubeka amapuleti. Imibala ye-granite enikezwa yi-ZhongHui ibangela ukukhanya okuncane, okusho ukuthi amehlo awanzima kangako kubantu abasebenzisa amapuleti. Sikhethe izinhlobo zethu ze-granite ngenkathi sicabangela ukwanda kokushisa ukuze sigcine lesi sici sincane.

IZICELO EZISEKELWE NGOKUZENZAKALELAYO

Uma uhlelo lwakho lokusebenza ludinga ipuleti elinezimo ezenziwe ngokwezifiso, izinto zokufaka ezinezintambo, izikhala noma okunye ukugaya, kuzodingeka ukhethe into efana ne-Black Diabase. Le nto yemvelo inikeza ukuqina okuphezulu, ukunciphisa ukudlidliza okuhle kakhulu, kanye nokusebenza kahle kokugaya.

Yebo, uma zingagugi kakhulu. Ukuhlelwa kwefektri yethu kanye nemishini kuvumela izimo ezifanele zokulinganisa ipuleti kahle kanye nokulungiswa kabusha uma kudingeka. Ngokuvamile, uma ipuleti lingaphakathi kwe-.001" yokubekezelelana okudingekayo, lingaphinde libekwe endaweni yalo. Uma ipuleti ligugiwe laze lafika ezingeni lapho lingaphezu kwe-.001" ekubekezelelaneni, noma uma linezimbobo noma lingcolile kabi, kuzodingeka lithunyelwe efektri ukuze ligaywe ngaphambi kokuphinda lihlanganiswe.

Kufanele kuqashelwe kakhulu ekukhetheni uchwepheshe wokulinganisa nokulungisa indawo. Sikukhuthaza ukuthi uqaphele ekukhetheni isevisi yakho yokulinganisa. Cela ukugunyazwa bese uqinisekisa ukuthi imishini ezosetshenziswa uchwepheshe inokulinganiswa okulandelekayo kweNational Inspection Institution. Kuthatha iminyaka eminingi ukufunda ukuthi ungayilalisa kanjani kahle i-granite enembile.

I-ZhongHui inikeza ukuguqulwa okusheshayo kokulinganiswa okwenziwa efektri yethu. Thumela amapuleti akho ukuze alinganiswe uma kungenzeka. Ikhwalithi kanye nedumela lakho kuncike ekunembeni kwezinsimbi zakho zokulinganisa kufaka phakathi amapuleti angaphezulu!

Amapuleti ethu amnyama anobukhulu obuphakeme kakhulu futhi aqinile ngokuphindwe kathathu. Ngakho-ke, ipuleti elenziwe ngomnyama akudingeki libe nobukhulu obufana nepuleti le-granite elinobukhulu obufanayo ukuze libe nokumelana okulinganayo noma okukhulu nokuphambuka. Ubukhulu obuncishisiwe busho isisindo esincane kanye nezindleko zokuthumela eziphansi.

Qaphela abanye abasebenzisa i-granite emnyama esezingeni eliphansi enobukhulu obufanayo. Njengoba kushiwo ngenhla, izakhiwo ze-granite, njengokhuni noma insimbi, ziyahlukahluka ngokwezinto ezibonakalayo nombala, futhi azibonisi ukuqina, ubulukhuni, noma ukumelana nokuguguleka. Eqinisweni, izinhlobo eziningi ze-granite emnyama kanye ne-diabase zithambile kakhulu futhi azifanele ukusetshenziswa kwepuleti elingaphezulu.

Cha. Imishini ekhethekile kanye nokuqeqeshwa okudingekayo ukuze kusetshenziswe kabusha lezi zinto kudinga ukuthi zibuyiselwe efektri ukuze zilinganiswe futhi ziphinde zisetshenziswe.

Yebo. I-Ceramic ne-granite zinezici ezifanayo, futhi izindlela ezisetshenziswa ukulinganisa nokuhlanganisa i-granite zingasetshenziswa nezinto ze-ceramic. I-Ceramic kunzima kakhulu ukuyihlanganisa kune-granite okubangela izindleko eziphakeme.

Yebo, uma nje izinto ezifakiwe zifihlwe ngaphansi kobuso. Uma izinto ezifakiwe zensimbi zigcwele noma zingaphezulu kobuso, kumele zibheke phansi ngaphambi kokuba ipuleti likwazi ukugoqwa. Uma kudingeka, singanikeza leyo nsizakalo.

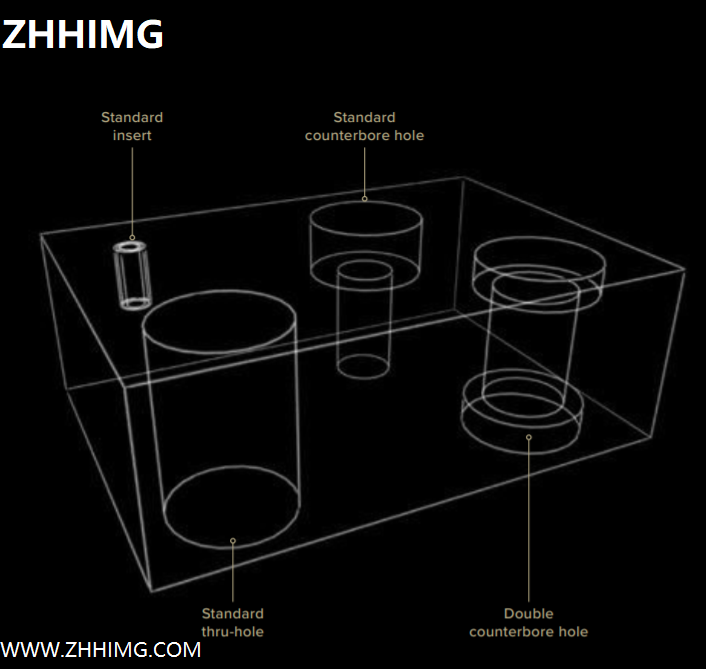

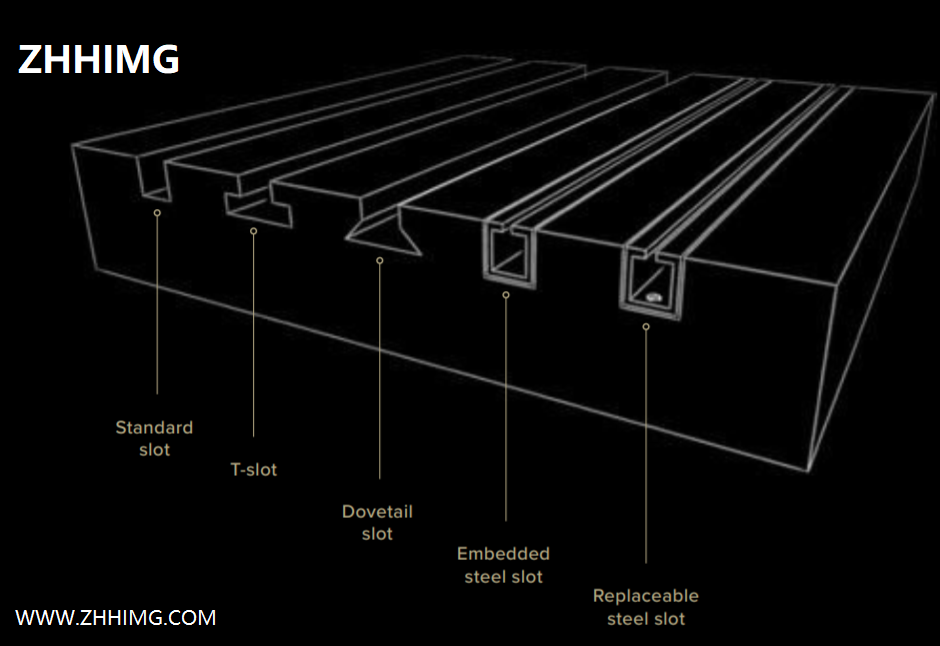

Yebo. Izithako zensimbi ezinentambo oyifunayo (isiNgisi noma i-metric) zingaboshelwa e-epoxy epuletini ezindaweni ozifunayo. I-ZhongHui isebenzisa imishini ye-CNC ukuhlinzeka ngezindawo zokufaka eziqinile kakhulu ngaphakathi kuka-+/- 0.005”. Kuma-inserts angabalulekile kangako, ukubekezelela kwethu indawo yama-inserts anezintambo kungu-±.060". Ezinye izinketho zifaka phakathi ama-T-Bar ensimbi kanye nezikhala ze-dovetail ezifakwe ngqo ku-granite.

Ama-insert ahlanganiswe kahle kusetshenziswa i-epoxy enamandla aphezulu kanye nomsebenzi omuhle azomelana namandla amaningi okugoba kanye nokusika. Esivivinyweni sakamuva, kusetshenziswa ama-insert anezintambo angu-3/8"-16, ilabhorethri yokuhlola ezimele ilinganise amandla adingekayo ukudonsa i-insert ene-epoxy epuletini elingaphezulu. Amapuleti ayishumi ahlolwe. Kulawa ayishumi, ezimweni eziyisishiyagalolunye, i-granite yaphuka kuqala. Umthwalo ojwayelekile endaweni yokwehluleka wawungama-10,020 lbs. we-granite empunga kanye nama-12,310 lbs. omnyama. Esimweni esisodwa lapho i-insert idonswa khona epuletini, umthwalo endaweni yokwehluleka wawungama-12,990 lbs.! Uma ingxenye yomsebenzi yakha ibhuloho ngaphesheya kwe-insert futhi kusetshenziswa i-torque enkulu, kungenzeka ukukhiqiza amandla anele okuphula i-granite. Ngokwengxenye ngenxa yalesi sizathu, i-ZhongHui inikeza iziqondiso ze-torque ephezulu ephephile engasetshenziswa ama-insert ane-epoxy: https://www.zhhimg.com/standard-thread-inserts-product/

Yebo, kodwa kuphela efektri yethu. Efektri yethu, singabuyisela cishe noma yiliphi ipuleti esimweni 'esifana nesentsha', ngokuvamile ngemali engaphansi kwengxenye yezindleko zokulishintsha. Imiphetho eyonakele ingalungiswa ngobuhle, imisele ejulile, ama-nick, kanye nemigodi kungagaywa, futhi izisekelo ezinamathiselwe zingashintshwa. Ngaphezu kwalokho, singaguqula ipuleti lakho ukuze landise ukuguquguquka kwalo ngokufaka izinsimbi eziqinile noma ezinentambo kanye nezikhala zokusika noma izindebe ezibambayo, ngokwezidingo zakho.

Kungani Kufanele Ukhethe I-Granite?

I-Granite uhlobo lwedwala eliyi-igneous elakhiwe eMhlabeni eminyakeni eyizigidi edlule. Ukwakheka kwedwala eliyi-igneous kwakuqukethe amaminerali amaningi njenge-quartz eqinile kakhulu futhi engagugi. Ngaphezu kokuqina nokumelana nokuguguleka, i-granite cishe inesilinganiso sokwanda njengensimbi ephonswe. Njengoba isisindo sayo sevolumu cishe siyingxenye yesithathu kunesensimbi ephonswe, i-granite kulula ukuyisebenzisa.

Ezisekelweni zomshini kanye nezingxenye ze-metrology, i-granite emnyama iwumbala osetshenziswa kakhulu. I-granite emnyama inephesenti eliphezulu le-quartz kuneminye imibala futhi, ngenxa yalokho, iyona eguga kakhulu.

I-granite iyonga kakhulu, futhi izindawo ezisikiwe zingaba yisicaba kakhulu. Akukhona nje ukuthi ingaxhunywa ngesandla ukuze kufezwe ukunemba okukhulu, kodwa ukuvuselela kungenziwa ngaphandle kokususa ipuleti noma itafula endaweni. Kungumsebenzi wokuhlanganisa ngesandla ngokuphelele futhi ngokuvamile kubiza kancane kakhulu kunokuvuselela kabusha insimbi ephonswe ngensimbi.

Lezi zimfanelo zenza i-granite ibe yinto efanelekile yokwakha izisekelo zomshini zosayizi owenziwe ngokwezifiso kanye nomklamo owenziwe ngokwezifiso kanye nezingxenye ze-metrology ezifanaipuleti lobuso begranite.

I-ZhongHui ikhiqiza imikhiqizo ye-granite eyenziwe ngokwezifiso eyenzelwe ukusekela izidingo ezithile zokulinganisa. Lezi zinto ezenziwe ngokwezifiso ziyahlukahluka kusukela ku-imiphetho eqondile toizikwele ezintathuNgenxa yemvelo ye-granite eguquguqukayo,izingxenyezingakhiqizwa nganoma yisiphi isayizi esidingekayo; ziyaguga futhi zihlala isikhathi eside.

Izinzuzo zamapuleti ongaphezulu e-Granite

Ukubaluleka kokulinganisa endaweni elinganayo kwasungulwa ngumsunguli waseBrithani uHenry Maudsley ngawo-1800. Njengomsunguli wamathuluzi omshini, wanquma ukuthi ukukhiqizwa okuqhubekayo kwezingxenye kudinga indawo eqinile ukuze kulinganiswe ngokwethembeka.

Uguquko lwezimboni lwadala isidingo sezindawo zokulinganisa, ngakho inkampani yobunjiniyela iCrown Windley yadala amazinga okukhiqiza. Izindinganiso zamapuleti obuso zaqala ukubekwa yiCrown ngo-1904 kusetshenziswa insimbi. Njengoba isidingo nezindleko zensimbi zanda, kwahlolwa ezinye izinto zokwakha ubuso bokulinganisa.

EMelika, umdali wesikhumbuzo uWallace Herman wasungula ukuthi i-granite emnyama yayiyindlela engcono kakhulu yokukhetha ipuleti elingaphezulu kunensimbi. Njengoba i-granite ingenawo amandla kazibuthe futhi ingagqwali, ngokushesha yaba indawo yokulinganisa ekhethwayo.

Ipuleti lobuso le-granite liwutshalomali olubalulekile lwezindawo zokucwaninga kanye nezindawo zokuhlola. Ipuleti lobuso le-granite elingu-600 x 600 mm lingafakwa esitendini sokusekela. Izitendi zinikeza ukuphakama kokusebenza okungu-34” (0.86m) ngamaphuzu amahlanu alungisekayo okulinganisa.

Ukuze uthole imiphumela yokulinganisa ethembekile nehambisanayo, ipuleti lobuso be-granite libalulekile. Njengoba ubuso bubushelelezi futhi buzinzile, kwenza amathuluzi akwazi ukuphathwa ngokucophelela.

Izinzuzo eziyinhloko zamapuleti ongaphezulu e-granite yilezi:

• Akubonisi ukukhanya

• Ayimelani namakhemikhali nokugqwala

• I-coefficient ephansi yokwandisa uma iqhathaniswa nensimbi yenqola ngakho-ke ayithinteki kangako ngokushintsha kwezinga lokushisa

• Kuqinile ngokwemvelo futhi kuyaguga

• Indiza yobuso ayithinteki uma iklwejwa

• Ngeke igqwale

• Akuyona i-magnetic

• Kulula ukuhlanza nokunakekela

• Ukulinganisa nokulungisa umphezulu kungenziwa endaweni

• Kufanelekela ukubhoboza izinto zokusekela ezinentambo

• Ukunciphisa ukudlidliza okuphezulu

Ezitolo eziningi, amakamelo okuhlola kanye nama-laboratory, amapuleti obuso be-granite aqondile athembelwa kuwo njengesisekelo sokulinganisa okunembile. Ngenxa yokuthi ukulinganisa ngakunye okuqondile kuncike endaweni enembile yokubhekisela lapho kuthathwa khona ubukhulu bokugcina, amapuleti obuso ahlinzeka ngendiza engcono kakhulu yokubhekisela yokuhlola umsebenzi kanye nokuhlelwa ngaphambi komshini wokugaya. Futhi ayizisekelo ezifanele zokwenza izilinganiso zokuphakama kanye nokulinganisa ubuso. Ngaphezu kwalokho, izinga eliphezulu lokusicaba, ukuzinza, ikhwalithi iyonke kanye nomsebenzi wobuciko kuzenza zibe ukukhetha okuhle kokufaka izinhlelo zokulinganisa eziyinkimbinkimbi zemishini, ze-elekthronikhi kanye nezokukhanya. Kunoma iyiphi yalezi zinqubo zokulinganisa, kubalulekile ukugcina amapuleti obuso elinganisiwe.

Ukulinganisa Okuphindaphindwayo Nokuthamba

Kokubili ukulinganisa okuyisicaba kanye nokuphindaphinda kubalulekile ukuqinisekisa ukuthi indawo inembile. Ukusicaba kungabhekwa njengamaphuzu onke ebusweni aqukethwe ngaphakathi kwezindiza ezimbili ezihambisanayo, indiza eyisisekelo kanye nendiza yophahla. Ukulinganisa ibanga phakathi kwezindiza kuwukusicaba okuphelele kobuso. Lokhu kulinganisa ukusicaba kuvame ukuba nokubekezelelana futhi kungafaka phakathi ukubizwa kwebanga.

Ukubekezelelana kwe-flatness kwamamaki amathathu ajwayelekile kuchazwa ku-federal specification njengoba kunqunywe yifomula elandelayo:

Ibanga Lelebhu AA = (40 + diagonal² / 25) x 0.000001 intshi (ehlangothini elilodwa)

Ibanga Lokuhlola A = Ibanga Lelebhu AA x 2

Ibanga Legumbi Lamathuluzi B = Ibanga Lelebhu AA x 4

Ngaphezu kokuba yisicaba, ukuphindaphinda kumele kuqinisekiswe. Ukulinganisa okuphindaphindiwe kuwukulinganisa izindawo ezisicaba zendawo. Kuwukulinganisa okuthathwa noma kuphi ebusweni bepuleti okuzophinda ngaphakathi kokubekezelelana okuchaziwe. Ukulawula ukuba yisicaba kwendawo kuya ekubekezelelaneni okuqinile kunokwesicaba jikelele kuqinisekisa ushintsho oluncane kancane kuphrofayili yokuba yisicaba ebusweni, ngaleyo ndlela kuncishiswe amaphutha endawo.

Ukuqinisekisa ukuthi ipuleti lobuso lihlangabezana kokubili nokucaciswa kokusicaba kanye nokulinganisa okuphindaphindiwe, abakhiqizi bamapuleti obuso be-granite kufanele basebenzise i-Federal Specification GGG-P-463c njengesisekelo semininingwane yabo. Leli zinga libhekana nokunemba kokulinganisa okuphindaphindiwe, izakhiwo zezinto ze-granite lobuso, ukuqeda kobuso, indawo yokusekela, ukuqina, izindlela ezamukelekayo zokuhlola kanye nokufakwa kwezinto ezifakwe ngentambo.

Ngaphambi kokuba ipuleti elingaphezulu liguge ngaphezu kwencazelo yokuthi libanzi kangakanani, lizobonisa izinsika ezigugile noma ezigobile. Ukuhlolwa kwanyanga zonke kwamaphutha okulinganisa okuphindaphindiwe kusetshenziswa i-gage yokufunda ephindaphindayo kuzobona izindawo zokuguguleka. I-gage yokufunda ephindaphindayo iyithuluzi elinembile kakhulu elithola iphutha lendawo futhi lingaboniswa ku-amplifier kagesi yokukhulisa okuphezulu.

Ukuhlola Ukunemba Kwepuleti

Ngokulandela iziqondiso ezimbalwa ezilula, ukutshalwa kwezimali epuletini lobuso be-granite kufanele kuhlale iminyaka eminingi. Kuye ngokusetshenziswa kwepuleti, indawo yesitolo kanye nokunemba okudingekayo, imvamisa yokuhlola ukunemba kwepuleti lobuso iyahlukahluka. Umthetho ojwayelekile uwukuthi ipuleti elisha lithole ukulungiswa kabusha okugcwele kungakapheli unyaka owodwa wokuthenga. Uma ipuleti lisetshenziswa njalo, kungcono ukufinyeza lesi sikhathi sibe yizinyanga eziyisithupha.

Ngaphambi kokuba ipuleti elingaphezulu liguge ngaphezu kwencazelo yokuthi libanzi kangakanani, lizobonisa izinsika ezigugile noma ezigobile. Ukuhlolwa kwanyanga zonke kwamaphutha okulinganisa okuphindaphindiwe kusetshenziswa i-gage yokufunda ephindaphindayo kuzobona izindawo zokuguguleka. I-gage yokufunda ephindaphindayo iyithuluzi elinembile kakhulu elithola iphutha lendawo futhi lingaboniswa ku-amplifier kagesi yokukhulisa okuphezulu.

Uhlelo lokuhlola olusebenzayo kufanele luhlanganise ukuhlolwa okuvamile nge-autocollimator, okuhlinzeka ngokulinganiswa kwangempela kobucaba obuphelele obungalandelelwa yi-National Institute of Standards and Technology (NIST). Ukulinganiswa okuphelele ngumkhiqizi noma inkampani ezimele kuyadingeka ngezikhathi ezithile.

Ukwehluka Phakathi Kokulinganisa

Kwezinye izimo, kukhona ukwehluka phakathi kokulinganiswa kwepuleti lobuso. Ngezinye izikhathi izici ezifana nokushintsha kobuso okubangelwa ukuguguleka, ukusetshenziswa okungalungile kwemishini yokuhlola noma ukusetshenziswa kwemishini engalinganiswanga kungabangela lokhu kwehluka. Nokho, izici ezimbili ezivame kakhulu izinga lokushisa kanye nokusekelwa.

Enye yezinto ezibaluleke kakhulu izinga lokushisa. Isibonelo, indawo engaphansi kungenzeka ukuthi igezwe ngesisombululo esishisayo noma esibandayo ngaphambi kokulinganiswa futhi ayivunyelwanga isikhathi esanele sokujwayela. Ezinye izimbangela zokushintsha kwezinga lokushisa zifaka phakathi umoya obandayo noma oshisayo, ukukhanya kwelanga okuqondile, ukukhanya okuphezulu noma eminye imithombo yokushisa okukhulu ebusweni bepuleti.

Kungaba khona futhi nokwehluka kwe-gradient yokushisa eqondile phakathi kobusika nehlobo. Kwezinye izimo, ipuleti alivunyelwe isikhathi esanele sokulungisa ngemva kokuthunyelwa. Kungumqondo omuhle ukurekhoda izinga lokushisa le-gradient eqondile ngesikhathi kwenziwa ukulinganisa.

Esinye isizathu esivamile sokwehluka kokulinganisa ipuleti elingasekelwanga kahle. Ipuleti elingaphezulu kufanele lisekelwe ezindaweni ezintathu, okungcono libe ngama-20% wobude ukusuka emaphethelweni epuleti. Izisekelo ezimbili kufanele zibe ngama-20% wobubanzi ukusuka emaceleni amade, kanti isekelo esisele kufanele sibe phakathi nendawo.

Amaphuzu amathathu kuphela angahlala ngokuqinile kunoma yini ngaphandle kwendawo enembile. Ukuzama ukusekela ipuleti ngamaphuzu angaphezu kwamathathu kuzokwenza ipuleti lithole ukwesekwa kwalo kusuka ezinhlanganisweni ezahlukene zamaphuzu amathathu, okungeke kube amaphuzu amathathu afanayo lapho lisekelwa khona ngesikhathi sokukhiqizwa. Lokhu kuzoletha amaphutha njengoba ipuleti liphambuka ukuze livumelane nelungiselelo elisha lokusekela. Cabanga ukusebenzisa izitendi zensimbi ezinemishayo yokusekela eyenzelwe ukuhambisana namaphuzu okusekela afanele. Izitendi zale njongo zivame ukutholakala kumkhiqizi wepuleti lokusekela.