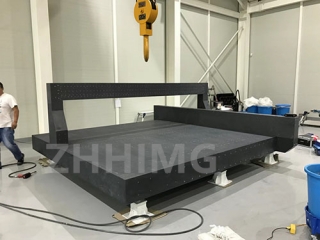

Eshabhuni yokukhiqiza i-semiconductor, izidingo zenqubo yokukhiqiza ama-chip ezimweni zemvelo nokunemba kwemishini zidlulele, futhi noma yikuphi ukuchezuka okuncane kungase kuholele ekwehleni okukhulu kwesivuno se-chip. Iplathifomu ye-XYZT yokunemba kwe-gantry yokunyakaza incike ezingxenyeni ze-granite ukuze ihlanganyele nezinye izingxenye zeplathifomu ukuze kwakhiwe isisekelo esiqinile sokuzuza ukunemba kwe-nanoscale.

Izakhiwo ezinhle kakhulu zokuvimbela ukudlidliza

Eshabhuni yokukhiqiza i-semiconductor, ukusebenza kwemishini yocingo kanye nabasebenzi abahambahambayo kungase kubangele ukudlidliza. Isakhiwo sangaphakathi sezingxenye zegwadle siminyene futhi siyafana, sinezici zemvelo ezimanzisa phezulu, "njengesithiyo" sokudlidliza. Uma ukudlidliza kwangaphandle kudluliselwa kuplathifomu ye-XYZT, ingxenye ye-granite inganciphisa ngempumelelo amandla okudlidliza angaphezu kuka-80% futhi inciphise ukuphazamiseka kokudlidliza ekunembeni kokunyakaza kweplathifomu. Ngesikhathi esifanayo, isiteji sifakwe uhlelo oluphezulu lwe-air float guide system, olusebenza ngokuhambisana nezingxenye ze-granite. Umhlahlandlela we-air float usebenzisa ifilimu yegesi ezinzile eyakhiwe igesi enomfutho ophezulu ukuze ibone ukunyakaza kokumiswa okungenakuxhumana kwezingxenye ezihambayo zeplathifomu futhi inciphise ukudlidliza okuncane okubangelwa ukungqubuzana komshini. Ngokuhlangene, lokhu okubili kuqinisekisa ukuthi ukunemba kokuma kweplathifomu kuhlala kugcinwa kuzinga le-nanometer ezinqubweni ezibalulekile ezifana ne-chip lithography nokunamathisela, futhi kugwenywe ukuchezuka kwamaphethini wesekethe ye-chip okubangelwa ukudlidliza.

Ukuzinza okuhle kakhulu kwe-thermal

Ukushintshashintsha kwezinga lokushisa kanye nomswakama endaweni yokusebenzela kunethonya elikhulu ekunembeni kwemishini yokukhiqiza ama-chip. I-coefficient yokwandisa okushisayo kwegwadle iphansi kakhulu, ngokuvamile ku-5-7 × 10⁻⁶/℃, usayizi ucishe ungashintshi uma izinga lokushisa lishintsha. Ngisho noma umehluko wezinga lokushisa phakathi kwemini nobusuku endaweni yokusebenzela noma ukukhiqizwa kokushisa kwemishini kubangela ukuthi izinga lokushisa le-ambient liguquguquke, izingxenye zegwadle zingahlala zizinzile ukuvimbela ukuwohloka kweplatifomu ngenxa yokwanda nokuncipha kwezinga lokushisa. Ngesikhathi esifanayo, ohlakaniphile yokulawula izinga lokushisa uhlelo ifakwe yesikhulumi uqaphe izinga lokushisa kuma ngesikhathi sangempela, ulungisa ngokuzenzakalelayo air conditioning kanye nemishini ukushisa ukushisa, futhi igcina izinga lokushisa workshop at 20 ° C ± 1 ° C. Kuhlanganiswe izinzuzo granite ukushisa ukuzinza, ukuqinisekisa ukuthi isiteji ekusebenzeni isikhathi eside, ukunemba ukunyakaza kwe-naxisno ukuze kuqinisekiswe ukunemba kwe-axisnometer ngayinye ukuqinisekisa ukunemba kwe-chip ngayinye Usayizi wephethini ye-chip lithography unembile, ukujula kwe-etching kufana.

Ukuhlangabezana nezidingo zendawo ehlanzekile

Isitolo sokukhiqiza ama-semiconductor sidinga ukugcina izinga eliphezulu lokuhlanzeka ukuvimbela izinhlayiya zothuli ukuthi zingangcolisi chip. I-Granite material ngokwayo ayikhiqizi uthuli, futhi ingaphezulu libushelelezi, akulula ukumunca uthuli. Ipulatifomu iyonke yamukela ukwakheka kwesakhiwo esivalwe ngokugcwele noma esivaleke kancane ukuze kuncishiswe ukungena kothuli lwangaphandle. Uhlelo lwangaphakathi lokujikeleza komoya luxhunywe nohlelo lwe-air conditioning oluhlanzekile lweshabhu ukuze kuqinisekiswe ukuthi ukuhlanzeka komoya kwangaphakathi kufinyelela ezingeni elidingwa ukwenziwa kwama-chip. Kule ndawo ehlanzekile, izingxenye ze-granite ngeke zithinte ukusebenza ngenxa yokuguguleka kothuli, futhi izingxenye ezibalulekile njengezinzwa zokunemba okuphezulu kanye nama-motor yesikhulumi nazo zingasebenza ngokuzinzile, zinikeze isiqinisekiso esiqhubekayo nesinokwethenjelwa sokunemba kwe-nanoscale sokukhiqiza i-chip, nokusiza imboni ye-semiconductor ukuthi ihambe iye ezingeni eliphezulu lenqubo.

Isikhathi sokuthumela: Apr-14-2025