Ama-spindle e-granite nama-worktable ayizingxenye ezibalulekile ekukhiqizweni kwamathuluzi omshini anembile kakhulu, izinsimbi zokulinganisa, kanye neminye imishini yezimboni. Adlala indima ebalulekile ekuqinisekiseni ukunemba nokuzinza kwale mishini, okubalulekile ekuhlangabezaneni nezidingo eziqondile zezimboni zanamuhla. Kodwa-ke, ukunemba nokuzinza kwama-spindle e-granite nama-worktable kungathinteka yizici ezahlukahlukene, kufaka phakathi amaphutha okukhiqiza, izakhiwo zezinto ezibonakalayo, kanye nezimo zemvelo. Ngakho-ke, kubalulekile ukuthatha izinyathelo ezifanele ukuqinisekisa ikhwalithi nokuthembeka kwazo.

Enye indlela ephumelelayo yokuqinisekisa ukunemba nokuzinza kwama-granite spindles nama-worktable tables ukusebenzisa umshini wokulinganisa ohlanganisayo (i-CMM) ukuze kuhlolwe futhi kuqinisekiswe. I-CMM iyithuluzi lokulinganisa elinembile kakhulu elinganikeza izilinganiso ezinembile nezithembekile zezinto eziyinkimbinkimbi ezinobukhulu obuthathu ngokunemba kwezinga eliphansi le-micron. Ngokusebenzisa i-CMM ukukala nokuqinisekisa ubukhulu, ukubekezelelana, kanye nezici zejiyometri zama-granite spindles nama-worktable tables, abakhiqizi bangabona noma yikuphi ukuphambuka noma amaphutha bese bethatha izinyathelo zokulungisa.

Uma usebenzisa i-CMM ukukala izingxenye ze-granite, kubalulekile ukucabangela izici eziningana ukuqinisekisa imiphumela enembile nethembekile. Okokuqala, i-CMM kufanele ilinganiswe futhi iqinisekiswe njalo ukuqinisekisa ukunemba kwayo nokuzinza. Lokhu kungafezwa ngokwenza ukulinganiswa okulandelekayo kwe-CMM ngokwezindinganiso zomhlaba wonke, njenge-ISO 10360. Okwesibili, inqubo yokulinganisa kufanele ihlelwe futhi yenziwe ngokucophelela ukuze kugwenywe amaphutha okulinganisa nokuqinisekisa ukuphindaphindeka. Lokhu kuhlanganisa ukukhetha amasu okulinganisa afanele, ukusetha ama-probe okulinganisa afanele, nokukhetha ozimele bezinkomba ezifanele kanye nezinhlelo zokuxhumanisa.

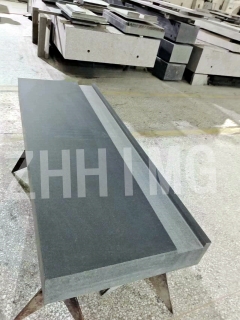

Esinye isici esibalulekile sokuqinisekisa ikhwalithi yezipini ze-granite namatafula okusebenza ukulawula inqubo yokukhiqiza ngokucophelela. Lokhu kuhilela ukusebenzisa izinto zokusetshenziswa ezisezingeni eliphezulu, njenge-granite ehlanzekile kakhulu ene-coefficients yokwandisa ukushisa okuphansi kanye nokuqina okuhle kwemishini, kanye nokusebenzisa amasu okukhiqiza athuthukile, njengokugaya ngokunemba, ukugoqa, kanye nokupholisha. Abakhiqizi kufanele futhi bathathe izinyathelo zokugwema amaphutha esakhiwo, njengemifantu, izikhala, kanye nokufakwa, okungathinta ukuzinza kanye nezakhiwo zemishini zezingxenye ze-granite.

Izimo zemvelo zingathinta nokunemba nokuzinza kwezingxenye ze-granite. Isibonelo, ukushintshashintsha kwezinga lokushisa kungabangela ukwanda kokushisa noma ukufinyela kwe-granite, okuholela ekushintsheni kobukhulu kanye nokuguquguquka. Ukuze kuncishiswe imiphumela yokungazinzi kokushisa, abakhiqizi bangathatha izinyathelo ezahlukahlukene, njengokufaka izivalo ezizinzile zokushisa, besebenzisa amasu okunciphisa ukushisa, kanye nokunciphisa imithombo yokushisa eduze kwezingxenye zomshini we-granite. Ngokufanayo, ukushintshashintsha komswakama kungabangela izinguquko zobukhulu ngenxa yokumuncwa komswakama noma ukumuncwa. Ukuze kugwenywe lokhu, abakhiqizi bangagcina futhi basebenzise izingxenye ze-granite endaweni enomswakama elawulwayo.

Ekuphetheni, ukuqinisekisa ukunemba nokuzinza kwezipini ze-granite kanye namatafula okusebenza kubalulekile ekufinyeleleni ukunemba okuphezulu nokuthembeka ezinqubweni zokukhiqiza zanamuhla. Ngokusebenzisa amasu okulinganisa nokuhlola athuthukile, ukulawula inqubo yokukhiqiza, kanye nokunciphisa imiphumela yezimo zemvelo, abakhiqizi bangakhiqiza izingxenye ze-granite ezisezingeni eliphezulu ezihlangabezana nezidingo eziqinile kakhulu zomkhakha.

Isikhathi sokuthunyelwe: Ephreli-09-2024