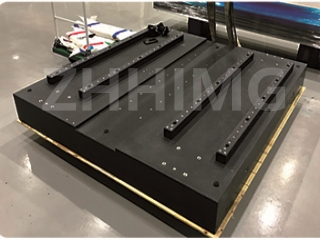

I-Granite ingenye yezinto ezivame kakhulu ezisetshenziselwa isisekelo samathuluzi omshini we-CNC ngenxa yokuqina kwayo okuhle kakhulu, ukuzinza, kanye nokunemba. Kodwa-ke, ukudlidliza nomsindo kungenzeka ngesikhathi sokusebenza kwemishini ye-CNC, okungaba nomthelela omubi ekusebenzeni nasekunembile komshini. Kulesi sihloko, sizoxoxa ngezindlela ezithile zokunciphisa ukudlidliza nomsindo lapho isisekelo se-granite sisetshenziswa kumathuluzi omshini we-CNC.

1. Ukufakwa Okufanele

Esinye sezici ezibaluleke kakhulu okufanele uzicabangele lapho usebenzisa isisekelo se-granite sethuluzi lomshini we-CNC ukufakwa okufanele. Isisekelo se-granite kumele silinganiswe futhi siqiniswe phansi ukuze kuvinjelwe noma yikuphi ukunyakaza okungabangela ukudlidliza. Lapho ufaka isisekelo se-granite, ama-bolts e-anchor noma i-epoxy grout angasetshenziswa ukusiqinisa phansi. Isisekelo kufanele futhi sihlolwe njalo ukuqinisekisa ukuthi sihlala silinganisiwe futhi sivikelekile.

2. Omata Bokuzihlukanisa

Esinye isisombululo esisebenzayo sokunciphisa ukudlidliza nomsindo ukusebenzisa omatilasi abahlukanisayo. Lawa mata aklanyelwe ukumunca ukudlidliza nokushaqeka futhi angafakwa ngaphansi komshini ukuze kuncishiswe ukudluliselwa kokudlidliza phansi nasezindaweni ezizungezile. Ukusetshenziswa komatilasi abahlukanisayo kungathuthukisa kakhulu ukusebenza nokunemba komshini ngenkathi kunciphisa umsindo ongafuneki.

3. Ukumanzisa

Ukudambisa indle kuyindlela ehilela ukwengeza izinto emshinini ukuze kuncishiswe ukudlidliza nomsindo ongadingeki. Le ndlela ingasetshenziswa esisekelweni segranite ngokusebenzisa izinto ezifana nerabha, i-cork, noma i-foam. Lezi zinto zingafakwa phakathi kwesisekelo nomshini ukuze kuncishiswe ukudlidliza nomsindo. Izinto zokudambisa eziklanywe kahle futhi ezibekwe kahle zinganciphisa ngempumelelo ukuvela kwamaza okuzwakalayo angabangela ukudlidliza emshinini.

4. Amathuluzi Alinganiselayo

Amathuluzi alinganiselayo abalulekile ekunciphiseni ukudlidliza nomsindo. Izibambi zamathuluzi kanye ne-spindle yethuluzi lomshini we-CNC kumele zilinganiswe ukuze kugwenywe ukudlidliza okweqile ngesikhathi sokusebenza. Amathuluzi angalinganiseli angabangela ukudlidliza okweqile okungathinta kabi ukusebenza nokunemba komshini. Ukugcina uhlelo lwamathuluzi olulinganiselayo kunganciphisa kakhulu ukuvela kokudlidliza okungafuneki nomsindo ethuluzini lomshini we-CNC.

Isiphetho

Ukusebenzisa isisekelo segranite samathuluzi omshini we-CNC kuyisinqumo esihle kakhulu sokuqina nokunemba. Kodwa-ke, ukudlidliza nomsindo kungenzeka ngesikhathi sokusebenza komshini. Ngokulandela amasu ashiwo ngenhla, unganciphisa ngempumelelo ukudlidliza nomsindo. Ukufakwa okufanele, omata bokuhlukaniswa, ukudambisa, kanye namathuluzi alinganiselayo konke kuyizindlela ezisebenzayo zokufeza ukusebenza okubushelelezi nokuzolile kwemishini ye-CNC ngenkathi kugcinwa amazinga aphezulu okunemba.

Isikhathi sokuthunyelwe: Mashi-26-2024