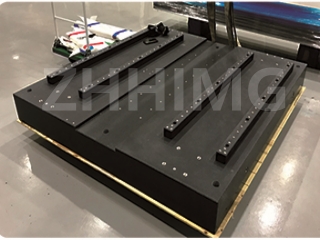

I-Granite iyinto ethandwayo yesisekelo semishini yokucubungula i-laser ngenxa yokuqina kwayo okuhle kakhulu, ukuqina, kanye nokumelana nokudlidliza. I-Granite ine-density ephezulu kanye ne-porosity ephansi kunezinsimbi eziningi, okwenza ingabi sengozini yokwanda nokuncipha kokushisa, okuqinisekisa ukunemba okukhulu kanye nokuqina ngesikhathi sokucubungula i-laser. Kulesi sihloko, sizoxoxa ngendlela yokusebenzisa isisekelo se-granite ekucubungulweni kwe-laser ngokuningiliziwe.

1. Ukukhetha uhlobo olufanele lwe-granite

Uma ukhetha isisekelo se-granite sokucubungula nge-laser, kubalulekile ukukhetha uhlobo olufanele lwe-granite olunezici ezifanele zokusetshenziswa okuhlosiwe. Izici okufanele uzicabangele zifaka:

- Ukumbozwa kwenhlabathi - khetha i-granite enezimbozwa ezincane ukuze ugweme ukungena kwamafutha, uthuli kanye nomswakama.

- Ubulukhuni - khetha uhlobo lwe-granite oluqinile njenge-Black Galaxy noma i-Absolute Black, olunobulukhuni be-Mohs obuphakathi kuka-6 no-7, okwenza lungagugi futhi ludabuke ngenxa yokusetshenziswa okuvamile.

- Ukuqina kokushisa - funa izinhlobo ze-granite ezine-coefficient ephezulu yokushisa enikeza ukuqina kokushisa okuhle kakhulu ngesikhathi sokucubungula nge-laser.

2. Ukuqinisekisa ukuthi isisekelo se-granite silinganisiwe futhi sizinzile

Imishini yokucubungula nge-laser ibucayi kakhulu, futhi noma yikuphi ukuphambuka okuncane kusuka endaweni eqondile kungabangela ukungalungi komkhiqizo wokugcina. Ngakho-ke, kubalulekile ukuqinisekisa ukuthi isisekelo se-granite lapho imishini ifakwe khona silinganisiwe futhi sizinzile. Lokhu kungafezwa ngokusebenzisa imishini yokulinganisa ngokunemba ukuhlola nokulungisa izinga lesisekelo bese usilungisa endaweni yaso usebenzisa ama-bolts noma i-epoxy.

3. Ukugcina isisekelo se-granite sihlanzekile futhi sinomswakama

Ukugcina ukuhlanzeka kanye nomswakama wesisekelo se-granite kubalulekile ukuqinisekisa ukuthi sihlala isikhathi eside futhi sisebenza kahle. I-granite isengozini yokudaya, futhi noma yikuphi ukusalela noma ukungcola okungaphezulu kungathinta kabi ukusebenza kwemishini yokucubungula nge-laser. Ngakho-ke, kubalulekile ukugcina isisekelo sihlanzekile futhi singenazo imfucuza ngokulandela izinqubo zokuhlanza ezinconywe ngumenzi.

Ngaphezu kwalokho, i-granite iyazwela ezinguqukweni zomswakama, futhi ukuchayeka isikhathi eside emazingeni aphezulu omswakama kungabangela ukuthi ikhule. Lokhu kungabangela izinkinga zokuqondanisa imishini, okuholela ezinkingeni zokunemba komkhiqizo. Ukuze kugwenywe lezi zinkinga, kunconywa ukuthi kugcinwe amazinga omswakama cishe ku-50% ngenkathi kugcinwa imishini kanye nesisekelo se-granite.

4. Ukuqinisekisa umoya owanele wesisekelo se-granite

Ngesikhathi sokucubungula nge-laser, imishini ikhiqiza ukushisa okumele kususwe. Ngakho-ke, isisekelo se-granite kumele sibe nomoya owanele wokuvimbela ukushisa ngokweqile. Lokhu kungafezwa ngokufakwa kwamafeni omoya noma amapayipi omoya aqondisa umoya oshisayo kude nemishini.

Ekuphetheni, ukusebenzisa isisekelo se-granite ekucubungulweni nge-laser kuyisinqumo esihle kakhulu ngenxa yokuqina kwayo okuphezulu, ukuzinza kanye nokumelana nokudlidliza. Kodwa-ke, kubalulekile ukukhetha uhlobo olufanele lwe-granite, ukuqinisekisa ukuthi isisekelo silinganisiwe futhi sizinzile, ukugcina amazinga okuhlanzeka kanye nomswakama, kanye nokunikeza umoya owanele ukuqinisekisa ukusebenza kahle. Ngokunakekelwa nokugcinwa okufanele, isisekelo se-granite singanikeza isisekelo esizinzile nesihlala isikhathi eside semishini yokucubungula i-laser iminyaka eminingi ezayo.

Isikhathi sokuthunyelwe: Novemba-10-2023