Njengoba ukukhiqiza komhlaba wonke kuhamba ngokuzimisela kuya ekunembeni okuphezulu, isivinini esiphezulu, kanye nokuzinza okukhulu, izinkampani zokukhiqiza izingxenye ezinembile zingaphansi kwengcindezi ekhulayo yokuletha hhayi nje kuphela ukubekezelelana okuqinile, kodwa futhi nokuthembeka kwesikhathi eside. Kulesi simo, izingxenye ze-granite ezinembile sezibe yingxenye eyisisekelo ezigabeni zokunyakaza ezinembile kakhulu, izinhlelo ze-metrology ezithuthukisiwe, kanye nemishini yezimboni ephezulu. Izakhiwo zazo zezinto ezihlukile zivumela amazinga okusebenza okunzima ukuwafinyelela ngezakhiwo zensimbi ezivamile.

Lesi sihloko sihlola ukukhiqizwa kwezingxenye ze-granite ezinembile, indima yazo ebalulekile ezinhlelweni zesiteji sokuhamba ezinembile kakhulu, kanye nezitayela zemboni ezibanzi ezibumba isidingo phakathi kwezinkampani zokukhiqiza izingxenye ezinembile eYurophu naseNyakatho Melika. Siphinde sichaze indlela i-ZHHIMG esekela ngayo amakhasimende omhlaba wonke ngezixazululo ze-granite eziklanywe ngobunjiniyela ezenzelwe izindawo zezimboni ezifuna kakhulu.

Izingxenye ze-Precision Granite: Izinzuzo zezinto ezibonakalayo kanye nenani lobunjiniyela

Izingxenye ze-granite eqondile zisetshenziswa kabanzi ezindaweni lapho ukuzinza kobukhulu, ukudambisa ukudlidliza, kanye nokuvumelana kokushisa kubalulekile. Uma kuqhathaniswa nezakhiwo zensimbi, insimbi ecijile, noma i-aluminium, i-granite inikeza inhlanganisela yezakhiwo ezibonakalayo ezihambisana eduze nezidingo zezinhlelo ezinembile kakhulu.

I-Granite ibonisa i-coefficient ephansi yokwanda kokushisa, okuvumela izingxenye ukuthi zilondoloze ukunemba kwejometri ngisho nangaphansi kwamazinga okushisa ashintshashintshayo. Lesi sici sibaluleke kakhulu kuizigaba zokunyakaza ezinembile kakhulu, lapho ukunemba kokubekwa kwezinga le-micron kanye nele-sub-micron kumele kulondolozwe kuyo yonke imijikelezo yokusebenza emide.

Ngaphezu kwalokho, isakhiwo sangaphakathi sekristalu segranite emnyama enobukhulu obuphezulu sinikeza ukudambisa okuhle kakhulu kokudlidliza. Lokhu kunciphisa ukudluliselwa kokuphazamiseka kwangaphandle futhi kuthuthukisa ukusebenza okuguquguqukayo kumapulatifomu okunyakaza, izinhlelo zokukhanya, kanye nemishini ye-semiconductor. Igranite nayo imelana nokugqwala ngokwemvelo futhi ayisebenzisi ugesi, okwenza ifaneleke ezindaweni ezihlanzekile kanye nezinhlelo zokulinganisa ezibucayi.

Izingxenye zeGranite Eziqondile Zokukhiqiza: Kusukela Etsheni Eliluhlaza Kuya Esakhiweni Esiqediwe

Ukukhiqizwa kwezingxenye ze-granite enembile kuyinqubo ekhethekile kakhulu ehlanganisa ukukhethwa kwezinto, imishini elawulwayo, kanye nokuhlolwa okunembile kakhulu. Ngokungafani nokucubungula amatshe okujwayelekile, ukukhiqizwa kwe-granite enembile kugxila ekufinyeleleni ukuthambekela okuyisicaba, ukunemba, kanye nokubekezelelana kwejometri okulinganiswe ngama-micron.

Inqubo iqala ngokukhetha ngokucophelela amabhlogo e-granite aluhlaza. I-granite kuphela enesakhiwo esifanayo sokusanhlamvu, ukuminyana okuphezulu, kanye neziphambeko ezincane zangaphakathi ezifanele ukusetshenziswa ngokunemba. Uma isikhethiwe, impahla idlula ezinqubweni zokukhululeka ekucindezelekeni kanye nokuguga ukuqinisekisa ukuzinza kwesikhathi eside.

Ukugaya nokugaya kwenziwa ezindaweni ezilawulwa amazinga okushisa kusetshenziswa imishini enembile. Ukugaya okungaphezulu, ukugoqa, kanye nokuqedela okuncane kuyasetshenziswa ukuze kufezwe ukuthamba okudingekayo kanyeikhwalithi yobuso. Ezingxenyeni eziyinkimbinkimbi, ukubhoboza ngokunemba, ukufaka izikhala, kanye nokufakwa okufakiwe kuhlanganiswe ngaphandle kokubeka engcupheni ubuqotho besakhiwo.

Kuyo yonke imisebenzi yokukhiqiza, ukuqinisekiswa kobukhulu kwenziwa kusetshenziswa amathuluzi okubhekisela alinganisiwe, izinhlelo zokulinganisa nge-laser, kanye nemishini yokulinganisa edidiyelwe. Lokhu kuqinisekisa ukuthi ingxenye ngayinye ye-granite enembile ihlangabezana nezidingo zokunemba ezibekiwe ngaphambi kokulethwa.

Izigaba Zokunyakaza Eziqondile Kakhulu: Izidingo Zesakhiwo kanye Nezishayeli Zokusebenza

Izigaba zokunyakaza ezinembile kakhulu zibalulekile ezinhlelweni zokusebenza ezifana ne-semiconductor lithography, ukuqondanisa okubonakalayo, ukucubungula nge-laser, kanye nezinhlelo zokuhlola ezithuthukisiwe. Lezi zigaba zidinga ukuqina okungavamile, ukuzinza kokushisa, kanye nokuncishiswa ukuze kufezwe ukunyakaza okuphindaphindwayo, okusheshayo, nokunemba okuphezulu.

Izakhiwo ezisekelwe ku-granite zinikeza isisekelo esifanele salezo zinhlelo.Izisekelo ze-granite eziqondilefuthi amabhuloho asekela ama-motor aqondile, ama-air bearings, kanye nezinhlelo zokuqondisa ngenkathi egcina ukuhambisana ngaphansi kwemithwalo enamandla. Izici zokunciphisa umswakama ze-granite zithuthukisa isikhathi sokuphumula futhi zinciphise amaphutha okubeka abangelwa ukudlidliza.

Emiklamo eminingi, izingxenye ze-granite zihlanganiswa nobuchwepheshe bokuthwala umoya ukuze kufezwe ukunyakaza okungenazihibe. Lokhu kuhlanganiswa kwenza kube lula ukubeka indawo ebushelelezi nephindaphindekayo ngokuguga okuncane, okusekela impilo yenkonzo ende kanye nezidingo zokunakekelwa ezincishisiwe.

Ukuhlanganiswa kwe-Precision Granite ku-Motion Stage Systems

Ukuhlanganiswa okuphumelelayo kwezingxenye ze-granite enembile ezigabeni zokunyakaza ezinembile kakhulu kudinga ukubambisana okuseduze phakathi kwabaklami bezinhlelo nabakhiqizi bezingxenye. Izici ezifana nokuklama isikhombimsebenzisi sokufaka, ukusatshalaliswa komthwalo, kanye nokuphathwa kokushisa kumele kucatshangelwe ekuqaleni kwenqubo yokuthuthukiswa.

Izakhiwo ze-granite ezenziwe ngokwezifiso zivame ukwakhiwa ukuze zivumelane nama-motor aqondile, izinhlelo ze-encoder, ukuphathwa kwekhebula, kanye nezidingo ze-vacuum noma zegumbi lokuhlanza. Izinkampani zokukhiqiza izingxenye ezinembile zithembela kakhulu ezixazululweni ze-granite ezenziwe ngokwezifiso kunezingxenye zekhathalogi ezijwayelekile ukuze zithuthukise ukusebenza kwesistimu.

I-ZHHIMG isebenzisana eduze nabakhiqizi bemishini ukuthuthukisa izisekelo ze-granite, ama-gantries, kanye namafreyimu ahambisana nezakhiwo ezithile zesiteji sokunyakaza. Le ndlela yokubambisana iqinisekisa ukuhambisana, ukunemba, kanye nokuzinza kwesikhathi eside ezinhlelweni zokusebenza ezidinga amandla.

Amathrendi Emboni Aqhuba Isidingo Sezingxenye Ze-Precision Granite

Izitayela eziningana zezinga elikhulu ziqhuba isidingo esikhulu sezingxenye ze-granite ezinembile kulo lonke elaseYurophu naseNyakatho Melika. Ukukhula okuqhubekayo kokukhiqizwa kwe-semiconductor kuye kwanda kakhulu izidingo zamapulatifomu omshini azinzile kakhulu kanye nezinhlelo zokuhlola. Ngesikhathi esifanayo, intuthuko ekukhanyeni, kuma-photonics, nasekukhiqizeni okusekelwe ku-laser iphakamise amathemba okunemba kokubeka kanye nokuzinza kwemvelo.

Ukuzenzakalela kanye nokukhiqizwa kwedijithali nakho kunegalelo kulokhu. Njengoba imigqa yokukhiqiza iba ngokuzenzakalelayo kakhulu, izinhlelo zokulinganisa eziqondile kanye nokunyakaza okusheshayo kumele zisebenze ngokuqhubekayo ngaphandle kokuzulazula okuncane. Izakhiwo ezisekelwe ku-granite zisiza ukuqinisekisa ukusebenza okulinganayo phakathi nesikhathi eside sokusebenza.

Lezi zici zibeke izingxenye ze-precision granite njengezinto eziyisisekelo ngaphakathi kwezintambo zokuhlinzeka zezinkampani ezihamba phambili zokukhiqiza izingxenye ezinembile.

Amakhono e-ZHHIMG ekukhiqizeni i-Precision Granite

I-ZHHIMG igxile ekukhiqizweni kwezingxenye ze-granite ezinembile kumakhasimende ezimboni zomhlaba wonke. Ngokuhlanganisa izinto ze-granite emnyama ezisezingeni eliphezulu nobuchwepheshe obuthuthukisiwe bokugaya nokuhlola ngokunembile, i-ZHHIMG iletha izingxenye ezihlangabezana nezindinganiso eziqinile zokunemba zomhlaba wonke.

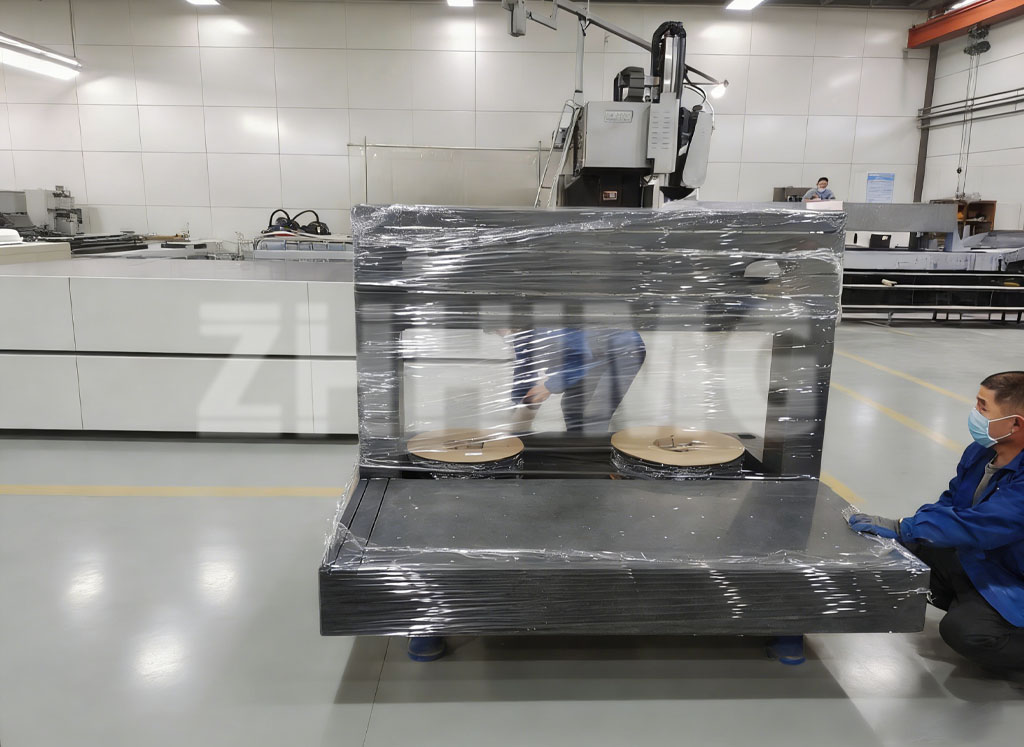

Iphothifoliyo yomkhiqizo yenkampani ifaka izisekelo zegranite zezigaba zokunyakaza ezinembile kakhulu, amapuleti obuso obunembile, ozimele bomshini, kanye nezakhiwo zegranite ezenziwe ngokwezifiso. Ingxenye ngayinye ikhiqizwa ngaphansi kwezimo zemvelo ezilawulwayo futhi iqinisekiswa ngezinqubo zokuhlola eziphelele.

Njengoba inesipiliyoni sokusekela amakhasimende emishinini ye-semiconductor, izinhlelo ze-metrology, kanye nokwenza izinto ngokuzenzakalela okusezingeni eliphezulu, i-ZHHIMG ayinikezi nje kuphela izingxenye, kodwa futhi nokusekelwa kobuchwepheshe kuyo yonke inqubo yokuklama nokuhlanganisa.

Isiphetho

Njengoba ukukhiqizwa kokunemba okuphezulu kuqhubeka nokuthuthuka, indima yezingxenye ze-granite enembile ezinhlelweni zokunyakaza kanye nemishini ye-metrology izokhula ngokubaluleka. Inhlanganisela yazo eyingqayizivele yokuzinza kokushisa, ukudambisa ukudlidliza, kanye nokuqina kuzenza zibe ukukhetha okuthandwayo kwezigaba zokunyakaza okunembile kakhulu kanye nezicelo zezimboni eziphezulu.

Ezinkampanini zokukhiqiza izingxenye ezinembile ezifuna izixazululo ezithembekile nezihlala isikhathi eside, izakhiwo ezisekelwe ku-granite zinikeza ukusebenza okucacile kanye nezinzuzo zomjikelezo wokuphila. Ngobuchwepheshe obuzinikele ekukhiqizeni i-granite enembile, i-ZHHIMG isalokhu izibophezele ekusekeleni amakhasimende omhlaba wonke ngezixazululo ezithuthukisiwe ezihlangabezana nezidingo ezishintshayo zemboni yanamuhla.

Isikhathi sokuthunyelwe: Jan-21-2026