Njengoba imboni ye-semiconductor iphishekela ngamandla ama-node enqubo ye-sub-2nm, umkhawulo wephutha lomshini usuphelile cishe. Kulesi simo esibucayi, ukuzinza kwegumbi lenqubo akuseyona inkinga yesibili; kuyisithiyo esiyinhloko sokukhiqiza. Kwa-ZHHIMG, sibona ushintsho oluyisisekelo endleleni ama-OEM omhlaba wonke asondela ngayo ekuqineni kwesakhiwo semishini ye-semiconductor capital.

I-Physics of Silence: Amasu Okudambisa Ukudlidliza Okuthuthukisiwe

Ekwenziweni kwe-wafer yesimanje, ukudlidliza okwakubhekwa “njengomsindo wangemuva” manje sekuyinto eyinhlekelele. Kungakhathaliseki ukuthi yi-micro-oscillations evela ohlelweni lwe-HVAC lwesikhungo noma i-inertia yangaphakathi yesigaba sokuskena ngesivinini esikhulu, amandla angalawulwa ahumusha ngokuqondile amaphutha okumboza kanye namaphethini afiphele.

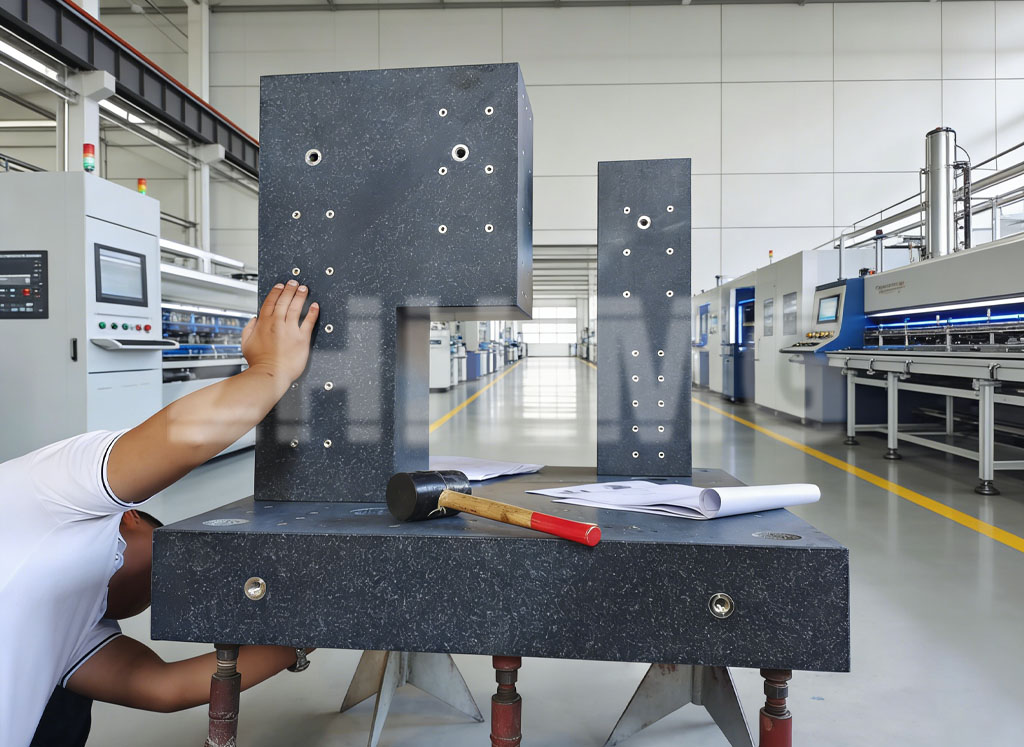

Amasu amanje okunciphisa ukudlidliza ekukhiqizweni kwe-semiconductor ashintshe aba ukwakheka okunezingqimba eziningi. Nakuba ukucindezela okungasebenzi—okusebenzisa izinto ezinobunzima obukhulu njengokukhipha amaminerali noma i-precision granite—kusalokhu kuyisisekelo, sibona ukwanda kokuhlanganiswa kokunciphisa okusebenzayo.

Izinhlelo ezisebenzayo zisebenzisa ama-actuator e-piezoelectric kanye nezinzwa zesikhathi sangempela ukuze "zikhansele" ukudlidliza ngokukhiqiza amaza aphikisayo. Kodwa-ke, ukusebenza kahle kwezinhlelo ezisebenzayo kunqunyelwe ngokwemvelo yisilinganiso sokudambisa sezinto eziyisisekelo. Yilapho ubuchwepheshe be-ZHHIMG ezintweni zokwakha ezimanzi kakhulu buba yinto ebalulekile. Ngokuhlanganisa ama-elekthronikhi asebenzayo ne-granite engasebenzi ngokwemvelo noma isisekelo esihlanganisiwe, sinikeza "Indawo Ethule" lapho ukubeka khona i-nano kungenzeka khona ngaphandle kokuphazamiseka.

Ukuvela Kokunyakaza Okungashayisani: Ubuchwepheshe Bokuthwala Umoya

Isidingo sokusetshenziswa okuphezulu komthamo siye sacindezela ama-bearings endabuko emikhawulweni yawo. Ukungqubuzana kuholela ekushiseni, kanti ukushisa kuholela ekwandeni kokushisa—isitha sokunemba. Lokhu kuholele ekwamukelweni kabanzi kwe-ubuchwepheshe bokuthwala umoya bezigaba zokunemba.

Ama-air bearings asekela umthwalo efilimini elincane lomoya ocindezelwe, ngokuvamile ubukhulu bawo bungama-micron ambalwa. Ngenxa yokuthi akukho ukuthintana ngokomzimba, akukho ukungqubuzana okungaguquki (ukuqina). Lokhu kuvumela:

-

Ukunyakaza Okungena-Hysteresis: Ukuqinisekisa ukuthi isigaba sibuyela ku-nanometer coordinate efanayo njalo.

-

Ukuhlala Ushesha: Kubalulekile ekuskeni izinhlelo zokusebenza ezifana nokuhlolwa kwe-E-beam lapho ngisho "nokugoba" okuncane kakhulu kwebhereyina lomshini kungaphazamisa isithombe.

-

Ukuphila Isikhathi Eside Kakhulu: Njengoba kungekho zingxenye ezithintayo, akukho ukuguguleka futhi akukho ukukhiqizwa kwezinhlayiya, okwenza zifaneleke kakhulu ezindaweni zokuhlanza zeKlasi 1.

Kwa-ZHHIMG, sakha izindawo ze-granite ezisicaba kakhulu ezisebenza njengezindlela zokuqondisa zalezi zibhebhe zomoya. Ukuze zisebenze kahle, lezi zindawo kumele zihlanganiswe zibe yizicaba ezilinganiswa ngamaqhezu obubanzi bokukhanya.

Amathrendi Emishini Yezimali Eziyi-Semiconductor: 2026 Nangaphambili

Njengoba siqhubeka nonyaka ka-2026,izitayela zemishini yezimali ze-semiconductorzichazwa ngokuthi “Izinsika Ezintathu”: Ukuguquguquka, Ukusimama, kanye Nokulawula Ukushisa.

-

Umklamo Wepulatifomu Eyi-Modular: Ama-OEM afuna amamojula esisekelo "esihlanganisiwe futhi sidlale". Esikhundleni sokuklama isisekelo esisha sawo wonke amathuluzi, asebenzisa izisekelo eziqondile ze-ZHHIMG ezingashintshwa ukuze zisetshenziswe njenge-lithography, i-metrology, noma i-etching.

-

Ukuphathwa Kokushisa: Njengoba imithombo yokukhanya ye-EUV (Extreme Ultraviolet) ikhiqiza ukushisa okukhulu, isisekelo somshini kumele sisebenze njengesinki esikhulu sokushisa. Sihlanganisa iziteshi zokupholisa eziyinkimbinkimbi ngqo ezingxenyeni zethu zamaminerali ne-granite ukuze silondoloze i-delta engu-$<0.01^\circ\text{C}$.

-

Ukuhambisana kwe-Vacuum: Njengoba izinqubo eziningi zingena ezindaweni ezine-vacuum ephezulu, izinto ezisetshenziswayo kumele zingabi nagesi. Ukucubungula kwethu okukhethekile kwe-granite kanye ne-ceramic kuqinisekisa ukuthi ubuqotho be-vacuum abukaze buphazamiseke yisisekelo sesakhiwo.

Ubambiswano Oluhlelekile ne-ZHHIMG

I-ZHHIMG ayiyona nje inkampani ekhiqiza izingxenye; singumlingani oqavile ochungechungeni lokuhlinzeka ngokulawula ukunyakaza. Isikhungo sethu eShayina sisebenza ngokubambisana eduze namaqembu onjiniyela eSilicon Valley nase-Eindhoven ukuxazulula izinselele ezinzima kakhulu zokuzinza embonini.

Ngokusebenzisa amasu ethu okubopha kanye nokuqonda kwethu okujulileamasu okunciphisa ukudlidliza, senza amakhasimende ethu akwazi ukudlula imingcele yoMthetho kaMoore. Kungakhathaliseki ukuthi uthuthukisa ithuluzi lesizukulwane esilandelayo le-ALD (Atomic Layer Deposition) noma i-wafer prober esheshayo, isisekelo siqala nge-ZHHIMG.

Isiphetho

Ukuvela kokukhiqizwa kwe-semiconductor kuwumncintiswano ophikisana nemithetho yefiziksi. Njengoba imboni iqhubekela phambili ngo-2026, ukugxila ekuqondeni kokuthwala umoya kanye nokunciphisa okuthuthukisiwe kuzoqhubeka nokuqina. Ukuhlala phambili kwalezi zindlela kudinga isisekelo—kokubili ngokoqobo nangokomfanekiso—esakhelwe phezu kobuchwepheshe kanye nokusungula izinto ezintsha.

Isikhathi sokuthunyelwe: Jan-26-2026