Ensimini enkulu yokukhiqiza ngokunemba kanye nocwaningo lwesayensi olusezingeni eliphezulu, ipulatifomu yomoya ocindezelayo oqondile oqondile ohamba ngokunemba okuphezulu inendawo ebalulekile, futhi isibusiso sesisekelo sokunemba se-granite, kodwa futhi ivumele ukusebenza kwayo njengamaphiko e-tiger, ukuthi kudlale indima emikhakheni eminingi.

Ukukhiqizwa kwe-semiconductor: isiqinisekiso esiyinhloko sokunemba kwe-chip

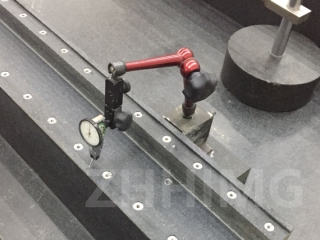

Ukukhiqizwa kwama-chip e-semiconductor kubizwa ngokuthi "igugu lomqhele" lobuchwepheshe besimanje, futhi izidingo zokunemba zenqubo ngayinye zifinyelele izinga elicishe libe nzima. Esigabeni se-photolithography, iphethini yesekethe ku-chip idinga ukudluliselwa ebusweni be-wafer ngokunemba kwe-nanometer. Ipulatifomu yokuntanta yomoya ocindezelwe kahle enesisekelo sokunemba kwe-granite, inganikeza ukwesekwa okuzinzile kakhulu kanye nokulawula ukunyakaza okunembile. Ukuqina okuhle kwesisekelo se-granite kuvikela ngempumelelo ukuphazamiseka kokudlidliza kwangaphandle, futhi i-coefficient yayo yokukhulisa ephansi iqinisekisa ukuzinza kobukhulu lapho kushintshashintsha izinga lokushisa, ukuze ukunemba kokubeka i-wafer kungafika kuma-nanometer. Lokhu kubekwa okunembile kuhlinzeka ngesisekelo esiqinile semishini ye-lithography ukudweba amaphethini wesekethe ngokunembile, kuthuthukise kakhulu ukuhlanganiswa kwama-chip kanye nokukhiqiza, kusize imboni ye-semiconductor ukuthi iqhubeke nokudlula umkhawulo wenqubo, idale ama-chip anamandla kakhulu, amancane, asetshenziswa kabanzi kuma-smart phone, amakhompyutha, ubuhlakani bokwenziwa kanye neminye imikhakha, futhi kukhuthaze intuthuko eqhubekayo yemishini ye-elekthronikhi ibe nokusebenza okuncane nokuphezulu.

Ukukhiqizwa kokunemba kokukhanya: Ukuqopha itshe lesisekelo lombono ocacile

Ukukhiqizwa kwamalensi optical, amalensi nezinye izingxenye kudinga ukunemba okuphezulu kakhulu kobuso kanye nokunemba kokuma, futhi noma yikuphi ukukhubazeka okuncane kungathinta ikhwalithi yezithombe ze-optical. Isisekelo sokunemba se-granite esiqondile somoya oqinile ohambayo sidlala indima ebalulekile kulo mkhakha. Ngesikhathi senqubo yokugaya ilensi, ipulatifomu ingaqhuba ithuluzi lokugaya ukuthi licubungule ubuso belensi nge-micron noma ngisho nokunemba kwe-sub-micron, ukuqinisekisa ukuthi ukuthamba kobuso belensi kuhlangabezana nezidingo zomklamo. Ukuqina okuphezulu kwesisekelo se-granite kuqinisekisa ukunemba kwendawo ehlobene yelensi kanye nethuluzi lokugaya ngesikhathi senqubo yokugaya, ukugwema amaphutha okugaya abangelwa ukudlidliza noma ukufuduka. Enkambisweni yokugaya, ukwesekwa kwayo okuzinzile kuvumela imishini yokugaya ukuthi isebenzise amandla afanayo, idale amalensi optical anencazelo ephezulu, aphansi. Lawa malensi asezingeni eliphezulu asetshenziswa kabanzi emishinini yezithombe ephezulu, kuma-microscope ezokwelapha, kuma-telescope ezinkanyezi nakwezinye izinsimbi zokukhanya, ethula umhlaba obonakalayo ocacile futhi obucayi kubantu, kodwa futhi ahlinzeka ngezingxenye ezibalulekile zokukhanya zokuxilonga kwezokwelapha, ukubuka kwasezulwini kanye neminye imisebenzi yocwaningo lwesayensi, okusiza ukuhlola imfihlakalo yomhlaba omncane nowe-macro.

Ukukhiqizwa kwezindiza: Ukusekelwa okuqinile kokusebenza kwezindiza

Ukukhiqizwa kwezindiza kuhlobene nokuphepha kwezwe kanye namandla esayensi nobuchwepheshe, futhi ukunemba kwezingxenye kuqinile kakhulu. Isisekelo sokunemba kwe-granite sepulatifomu entantayo yomoya ocindezelekile oqondile sibalulekile ekusetshenzisweni kwe-blade yenjini ye-aero kanye nokukhiqizwa kwezingxenye zesakhiwo sezindiza. Lapho kucutshungulwa ama-blade enjini ye-aero, kuyadingeka ukulawula ngokunembile indlela yamathuluzi ukuqinisekisa ukuthi ukunemba kwephrofayili ye-blade kuhlangabezana nezindinganiso zokuklama, ezithinta ngqo ukusebenza kahle kokushisa kanye nokujikijela kwenjini. Ipulatifomu entantayo yomoya ocindezelekile oqondile osekelwa yisisekelo sokunemba kwe-granite ingafinyelela ukulawula kokunyakaza okunembile, ukuze ithuluzi likwazi ukusika ngokunembile izinto ze-blade futhi liqinisekise ikhwalithi ye-blade. Ekukhiqizweni kwezingxenye zesakhiwo sezindiza, kungaba ukubhoboza, ukugaya noma ukuhlanganisa, ukubeka okunembile okuphezulu kanye nokunyakaza okuzinzile kwepulatifomu kuqinisekisa ukunemba kobukhulu kanye nokunemba kokuhlanganiswa kwezingxenye zesakhiwo, kuthuthukise amandla esakhiwo ngenkathi kunciphisa isisindo sendiza, kuthuthukise ukuphepha nokusebenza kwendiza, futhi kunikeze isiqinisekiso sokukhiqiza esiqinile sokuthuthukiswa kwemboni yezindiza. Ukukhuthaza ukuhlola kwesintu isibhakabhaka nendawo yonke.

Ucwaningo lwezokwelapha: isandla sokunene sokuhlola izimfihlakalo zokuphila

Emkhakheni wocwaningo lwezokwelapha, ukusebenza okunembile kanye nokubuka amasampula amancane kuyisihluthulelo sokuvula imfihlakalo yokuphila nokunqoba izifo ezinzima. Ipulatifomu yokuntanta yomoya ocindezelwe kahle enesisekelo sokunemba kwe-granite idlala indima ebalulekile ekulandeleni izakhi zofuzo, ukuphathwa kwamaseli amancane njalo njalo. Emishinini yokulandelana kwezakhi zofuzo, ipulatifomu ingahambisa ngokunembile islayidi yesampula, ukuze ithuluzi lokulandelana likwazi ukufunda ngokunembile ulwazi lwezakhi zofuzo, lithuthukise ukunemba nokusebenza kahle kokulandelana kwezakhi zofuzo, futhi linikeze ukwesekwa okuqinile kokuxilongwa kwezakhi zofuzo kanye nokwelashwa kwezifo komuntu siqu. Ekulawuleni amaseli amancane, abaqhubi basebenzisa ipulatifomu ukulawula ngokunembile ama-microneedles, ama-microstraw kanye namanye amathuluzi okujova nokukhipha amaseli ngamanye, okwenza kube lula ucwaningo olusezingeni eliphezulu njenge-biology yamaseli kanye nokwelashwa kwezakhi zofuzo, ukuhlinzeka ngokusekelwa kobuchwepheshe okubalulekile kokusungula izinto ezintsha kanye nokuthuthukiswa kobuchwepheshe bezokwelapha, kanye nokuletha ithemba elisha empilweni yabantu.

Ngokunemba kwayo okuhle kakhulu, ukuzinza kanye nokuqina, isisekelo sokunemba kwe-granite seplatifomu yokuntanta emoyeni enembile sesibe amandla ayisisekelo okusekela ezindaweni eziningi ezinezidingo zokunemba okuphezulu, futhi siyaqhubeka nokukhuthaza intuthuko yezimboni ezahlukahlukene ziye ohlangothini oluyinkimbinkimbi kakhulu, okufaka ugqozi oluqinile lwentuthuko yesayensi nezobuchwepheshe kanye nentuthuko yezenhlalo.

Isikhathi sokuthunyelwe: Ephreli-10-2025