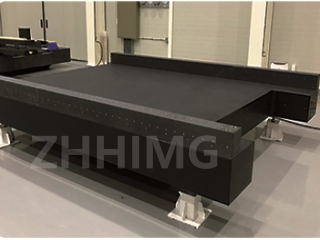

I-Granite uhlobo lwedwala eliyi-igneous elaziwa ngokuqina kwalo, ubulukhuni, kanye nokuqina. Lezi zimfanelo zenza i-granite ibe yinto efanelekile yezisekelo zomshini kanye nokusetshenziswa ekucubungulweni kwe-wafer. Kulesi sihloko, sizoxoxa ngezinzuzo kanye nokungalungi kokusebenzisa izisekelo zomshini we-granite ekucubungulweni kwe-wafer.

Izinzuzo ze-Granite Machine Base:

1. Ukuzinza: I-Granite ine-coefficient ephansi yokwanda kokushisa, okusho ukuthi ihlala izinzile ngisho noma ivezwe emazingeni okushisa aphezulu. Lokhu kuzinza kuqinisekisa ukuthi isisekelo somshini sihlala endaweni yaso futhi asishukumi ngesikhathi sokucubungula i-wafer.

2. Ukuqina: I-Granite ingenye yezinto eziqinile kakhulu, okwenza imelane kakhulu nokuguguleka. Lokhu kuqina kuqinisekisa ukuthi isisekelo somshini singamelana nokucindezela nokudlidliza okukhiqizwa ngesikhathi sokucubungula i-wafer.

3. Ukudlidliza Okuphansi: Ngenxa yokuzinza okungokwemvelo kanye nokuqina kwe-granite, ikhiqiza ukudlidliza okuncane ngesikhathi sokucubungula i-wafer. Lokhu kudlidliza okuphansi kunciphisa ingozi yokulimala kwe-wafer futhi kuqinisekisa ukunemba nokunemba ekucutshungulweni.

4. Ukunemba: Izinga eliphezulu lokuzinza kanye nokudlidliza okuphansi kwesisekelo somshini we-granite kuqinisekisa ukunemba ekucutshungulweni kwe-wafer. Lokhu kunemba kubalulekile ekudaleni ama-semiconductor asezingeni eliphezulu, adinga ukunemba enkambisweni yawo yokukhiqiza.

5. Ukulula Kokulungisa: I-Granite iyinto engenazimbobo, okwenza kube lula ukuyihlanza nokuyinakekela. Lokhu kunciphisa isikhathi kanye nomsebenzi odingekayo wokulungisa futhi kwandisa ukusebenza kahle kokusebenza kokucubungula i-wafer.

Okubi kwe-Granite Machine Base:

1. Izindleko: Enye yezinto ezimbi kakhulu ngezisekelo zomshini we-granite ukuthi zibiza kakhulu uma kuqhathaniswa nezinye izinto. Lokhu kungenxa yobunzima kanye nezindleko zokumba, ukuthutha, kanye nokubumba i-granite.

2. Isisindo: I-Granite iyinto ebanzi, okwenza ibe nzima futhi kube nzima ukuyihambisa. Lokhu kungenza kube nzima ukubeka kabusha isisekelo somshini ngesikhathi sokufakwa noma ukulungiswa.

3. Ubunzima Bomshini: I-Granite iyinto eqinile futhi ekhuhlayo, okwenza kube nzima ukuyishicilela nokuyibumba. Lokhu kungandisa isikhathi nezindleko ezidingekayo ukwakha isisekelo somshini.

Isiphetho:

Ukusetshenziswa kwezisekelo zomshini we-granite ekucubungulweni kwe-wafer kunikeza izinzuzo eziningi, okuhlanganisa ukuzinza, ukuqina, ukudlidliza okuphansi, ukunemba, kanye nokulula kokugcinwa. Kodwa-ke, lezi zinzuzo ziza ngezindleko eziphakeme futhi zidinga imishini ekhethekile kanye nobuchwepheshe bokukhiqiza nomshini wesisekelo somshini we-granite. Naphezu kwalezi zingqinamba, izinzuzo zezisekelo zomshini we-granite zizenza zibe ukukhetha okuthandwayo kwemisebenzi yokucubungula i-wafer lapho ukunemba nokunemba kubalulekile khona.

Isikhathi sokuthunyelwe: Novemba-07-2023