Amadivayisi okubeka ama-waveguide optical asetshenziselwa ukubeka ama-waveguide optical ngokunembile ezinhlotsheni ezahlukene zokusebenza, kusukela kwezokuxhumana kuya kumadivayisi ezokwelapha. Uma kukhulunywa ngokukhiqizwa kwala madivayisi, ukukhetha indlela yokuhlanganisa kungathinta kakhulu ikhwalithi yawo, ukuqina, kanye nokusebenza kwawo.

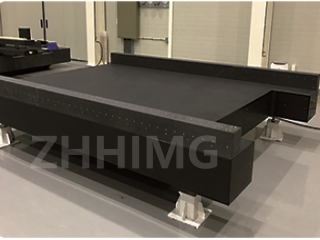

Enye yezindlela ezizuzisa kakhulu zokuhlanganisa amadivayisi okubeka amagagasi e-optical ukuhlanganisa i-granite. I-Granite iyinto eqinile futhi engenazo izimbobo enikeza izinzuzo eziningi kunezinye izinto ezifana ne-aluminium noma ipulasitiki.

Okokuqala, i-granite izinzile kakhulu futhi inomthamo ophansi wokukhula kokushisa. Lokhu kusho ukuthi ngeke ikhule noma inciphe kakhulu ngokushintsha kwezinga lokushisa, okuqinisekisa ukuthi amadivayisi ahlala eqinile futhi ethembekile ngisho nasezindaweni ezinzima. Lokhu kuzinza kubaluleke kakhulu ekusetshenzisweni okunembile, njengokuxhumana ngocingo, lapho indawo yama-waveguides kufanele ibe nenembile futhi ihambisane.

Okwesibili, i-granite iqinile kakhulu futhi ihlala isikhathi eside. Ayiklwebheki noma yonakale kalula, okwenza ibe yindawo ekahle yokusetshenziswa ezindaweni zokukhiqiza lapho amadivayisi angase aguge futhi adabuke khona. I-granite iphinde imelane nokugqwala kwamakhemikhali, okubalulekile ekusetshenzisweni lapho amadivayisi angase ahlangane namakhemikhali angalimaza ezinye izinto.

Ngaphezu kwalokho, ubukhulu be-granite buyenza ibe yinto enhle kakhulu yokunciphisa ukudlidliza. Lokhu kubalulekile kumadivayisi okubeka amagagasi okukhanya lapho ngisho nokudlidliza okuncane kungaphazamisa ukusebenza kwesistimu. Ukusetshenziswa kwe-granite kungasiza ekumunceni lokhu kudlidliza, kuqinisekiswe ukuthi amadivayisi ahlala eqinile futhi ethembekile.

Ngaphezu kwezakhiwo zayo ezibonakalayo, ukuhlanganiswa kwe-granite kunikeza nezinzuzo eziningi ezisebenzayo. Isibonelo, i-granite ingashintshwa ngomshini ukuze ikwazi ukumelana kahle kakhulu, okuqinisekisa ukuthi amadivayisi akhiqizwa ngokunembile ngokwezidingo eziqondile. I-granite kulula futhi ukuyihlanza nokuyinakekela, okuqinisekisa ukuthi amadivayisi ahlala ehlanzekile futhi engenazo izinto ezingcolisayo.

Okokugcina, i-granite kulula kakhulu ukuyisebenzisa futhi ingacutshungulwa kusetshenziswa amasu ahlukahlukene, okuhlanganisa ukushintshwa kwe-CNC, ukugaya, kanye nokupholisha. Lokhu kuguquguquka kwenza kube ukukhetha okuthandwayo kwezinhlelo zokusebenza ezahlukahlukene, hhayi nje amadivayisi okubeka amagagasi okukhanya.

Ekuphetheni, izinzuzo zokuhlanganiswa kwe-granite kwamadivayisi okubeka amagagasi okukhanya zicacile. Ukuqina kwe-granite, ukuqina kwayo, ukumelana nokugqwala kanye nezakhiwo zokunciphisa ukudlidliza kwenza kube ukukhetha okuhle kakhulu kokusetshenziswa okunembile lapho ukunemba nokuthembeka kubalulekile khona. Ngaphezu kwalokho, ukulula komshini nokugcinwa kwayo kwenza kube ukukhetha okusebenzayo nokungabizi kakhulu kwabakhiqizi.

Isikhathi sokuthunyelwe: Disemba-04-2023