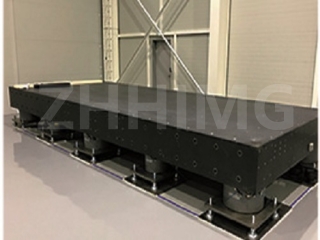

Izingxenye ze-granite mechanical zivame ukusetshenziswa kumadivayisi okucubungula ngokunemba ngenxa yokuqina kwawo okuphezulu, ukuqina, kanye ne-coefficient ephansi yokukhula kokushisa. Kodwa-ke, lezi zingxenye zinezidingo ezithile zendawo yokusebenza ukuze zilondoloze ukusebenza kwazo nokuqinisekisa ukuthi aziwohloki ngokuhamba kwesikhathi. Kulesi sihloko, sizocabangela izidingo zezingxenye ze-granite mechanical zemikhiqizo yedivayisi yokucubungula ngokunemba endaweni yokusebenza kanye nendlela yokugcina indawo yokusebenza.

1. Izinga lokushisa

Izingxenye ze-granite mechanical ziyazwela ekushintsheni kwezinga lokushisa. Izinga lokushisa elifanele lokusebenza kwezingxenye ze-granite lingu-20-25°C. Uma izinga lokushisa liphezulu kakhulu noma liphansi kakhulu, lingabangela izinguquko ebukhulu bezingxenye ze-granite. Ngakho-ke, kubalulekile ukuqinisekisa izinga lokushisa elihlala njalo endaweni yokusebenza ngokusebenzisa izinhlelo zokupholisa umoya noma zokushisa. Izinga lokushisa kufanele ligcinwe ngaphakathi kwebanga lika-18-26°C ukuqinisekisa ukulinganisa okunembile nokuzinzile.

2. Umswakama

Izingxenye ze-granite nazo zizwela umswakama kanye nomswakama. Amazinga aphezulu omswakama angabangela ukugqwala kanye nokuguguleka, okungathinta ukunemba kokulinganisa. Ngakho-ke, indawo yokusebenza kufanele igcinwe ezingeni lomswakama elingu-40-60%. Lokhu kungafezwa ngokusebenzisa ama-dehumidifier noma ngokuqinisekisa ukuthi umoya ungena kahle.

3. Ukudlidliza

Ukudlidliza kungabangela ukuthi izingxenye zegranite ziguge futhi zilahlekelwe ukunemba kwazo. Ngakho-ke, kubalulekile ukugwema imithombo yokudlidliza endaweni yokusebenza. Lokhu kungafezwa ngokuhlukanisa umshini noma imishini lapho izingxenye zifakwe khona endaweni ezungezile. Kunconywa futhi ukusebenzisa izinto ezibamba ukushaqeka ukuze kuncishiswe imiphumela yokudlidliza.

4. Uthuli kanye nemfucumfucu

Izingxenye ze-granite zisengozini yothuli kanye nemfucumfucu. Uthuli kanye nemfucumfucu kungabangela ukuguguleka, okuholela emaphutheni ekulinganisweni nasekuqondeni. Ngakho-ke, kubalulekile ukugcina indawo yokusebenza ihlanzekile ingenalo uthuli kanye nemfucumfucu. Lokhu kungafezwa ngokuhlanza njalo nokusula indawo yokusebenza.

5. Ukulungiswa

Ukugcinwa njalo kwezingxenye ze-granite kubalulekile ukuqinisekisa ukuthi zihlala isikhathi eside futhi zinembile. Izingxenye kufanele zihlolwe njalo ukuze kutholakale ukuthi ziyaguga noma cha. Noma yiziphi izimpawu zokuguga noma cha kufanele zilungiswe ngokushesha. Futhi, kufanele kwenziwe ukuhlolwa okuvamile kwemishini ukuqinisekisa ukuthi inembile.

Ekuphetheni, izingxenye ze-granite mechanical zidlala indima ebalulekile emikhiqizweni yedivayisi yokucubungula ngokunembile. Ukuqinisekisa ukuthi lezi zingxenye zisebenza kahle, kubalulekile ukugcina indawo yokusebenza elawulwayo nehlanzekile. Ukugcina izinga lokushisa elihlala likhona, umswakama, nokugwema ukudlidliza kubalulekile ukuze kulinganiswe ngokunembile. Uthuli kanye nemfucumfucu kufanele kugcinwe okungenani, futhi ukugcinwa njalo kwezingxenye kuyadingeka. Ngokulandela lezi ziqondiso, isikhathi sokuphila kwezingxenye ze-granite sizokwelulwa, futhi imikhiqizo yedivayisi yokucubungula ngokunembile izohlala inembile futhi ithembekile.

Isikhathi sokuthunyelwe: Novemba-25-2023