Imishini Yokulinganisela Enamandla, i-Soft-Bearing vs.

Imishini yokulinganisa izindiza ezimbili, noma imishini yokulinganisa enamandla, isetshenziselwa ukulungisa ukungalingani okungaguquguquki nokunamandla. Izinhlobo ezimbili ezijwayelekile zemishini yokulinganisa enamandla esethole ukwamukelwa okubanzi kakhulu umshini wokuthwala "othambile" noma oguquguqukayo kanye nomshini "oqinile" noma oqinile wokuthwala. Ngenkathi kungekho mehluko phakathi kwamabherethi asetshenzisiwe, imishini inezinhlobo ezahlukahlukene zokumiswa.

Soft Amabombo Ukulinganisela Machines

Umshini ophethe othambile uthola igama lawo eqinisweni lokuthi uyayisekela i-rotor ukuthi ilinganiswe ngamabhere akhululekile ukuhamba okungenani ohlangothini olulodwa, imvamisa ngokuvundla noma ngokuya ngqo eksisi le-rotor. Umbono walesi sitayela sokulinganisa ukuthi i-Rotor iziphatha sengathi imiswe phakathi nomoya ngenkathi ukunyakaza kwe-Rotor kukalwa. Ukwakhiwa komshini womshini othambile uthande ukuba yinkimbinkimbi ngokwengeziwe, kepha i-elekthronikhi ebandakanyekayo ilula uma iqhathaniswa nemishini ethwala kanzima. Idizayini yomshini wokulinganisa othwala othambile uyayivumela ukuthi ibekwe cishe noma yikuphi, njengoba umsebenzi oshintshashintshayo usekela ukuhlinzeka ngokuhlukaniswa kwemvelo nomsebenzi oseduze. Lokhu kuvumela nokuthi umshini unyakaziswe ngaphandle kokuthinta ukulinganiswa kwedivayisi, ngokungafani nemishini ethwala kanzima.

I-resonance ye-Rotor ne-bearing system yenzeka ngesigamu esisodwa noma ngaphansi kwesivinini sokulinganisa esiphansi. Ukulinganisa kwenziwa kumvamisa ophakeme kakhulu kunemvamisa ye-resonance yokumiswa.

Ngaphandle kokuthi umshini wokulinganisa othambile uthambile, unikeza izinzuzo ezingeziwe zokuba nokuzwela okuphezulu kunemishini ethwala kanzima ngejubane lokulinganisa eliphansi; imishini ethwala kanzima ilinganisa amandla adinga isivinini sokulinganisa esiphakeme. Inzuzo eyengeziwe ukuthi imishini yethu ethwala kancane iyalinganisa futhi ibonise ukunyakaza kwangempela noma ukufuduka kwe-Rotor ngenkathi izungeza enikeza izindlela ezakhelwe ngaphakathi zokuqinisekisa iqiniso lokuthi umshini uphendula kahle futhi i-Rotor ilinganiswe kahle.

Inzuzo enkulu yemishini ethwala izinto ezithambile ukuthi ijwayele ukwenza izinto ezihlukahlukene. Bangakwazi ukusingatha ububanzi bezinsimbi ezijikelezayo ngosayizi owodwa womshini. Asikho isisekelo esikhethekile esidingekayo sokwahlukanisa futhi umshini ungasuswa ngaphandle kokuthola ukulinganiswa kabusha kochwepheshe.

Imishini yokulinganisa ethambile, njengemishini ethwala kanzima, ingalinganisa ama-rotor amaningi aqonde ngqo. Kodwa-ke, ukulinganisa i-overhung rotor kudinga ukusetshenziswa kwengcezu yokunamathisela yokubamba umthwalo ongemuhle.

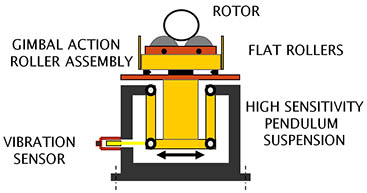

Isithombe esingenhla sikhombisa umshini wokulinganisa othambile. Qaphela ukuthi ukuma kohlelo lokuthwala kuvumela i-pendulum ukuthi ijike iye emuva naphambili ne-Rotor. Ukufuduswa kuqoshwa ngenzwa yokudlidliza futhi kamuva kusetshenziselwe ukubala ukungalingani okukhona.

Hard Bearing Ukulinganisela Machines

Imishini yokulinganisa ethwala kanzima inesisekelo somsebenzi oqinile futhi ithembele kuma-elekthronikhi asezingeni eliphakeme ukutolika ukudlidlizela. Lokhu kudinga isisekelo esikhulu, esiqinile lapho kufanele sisethwe unomphela futhi silinganiswe endaweni ngumkhiqizi. Umbono walesi simiso sokulinganisa ukuthi i-rotor ikhawulelwe ngokuphelele futhi namandla afakwa yi-rotor ezisekelweni ayalinganiswa. Ukudlidliza kwangemuva okuvela kwimishini eseduze noma umsebenzi ophansi komsebenzi kungathinta imiphumela yokulinganisa. Imvamisa, kusetshenziswa imishini ethwala kanzima ekwenzeni imisebenzi yokukhiqiza lapho kudingeka isikhathi esisheshayo somjikelezo.

Inzuzo enkulu emishinini ethwala kanzima ukuthi ijwayele ukuhlinzeka ukufundwa okungalingani kahle okusheshayo, okuwusizo ekulinganisweni kokukhiqizwa kwejubane.

Isici esikhawulela semishini ethwala kanzima isivinini sokulinganisa esidingekayo se-rotor ngesikhathi sokuhlolwa. Ngoba umshini ulinganisa amandla angalingani we-Rotor ejikelezayo, i-Rotor kufanele iphothwe ngejubane elikhulu ukukhiqiza amandla anele ukutholwa ukumiswa okuqinile.

Isiswebhu

Kungakhathalekile ukuthi kusetshenziswe umshini wokulinganisa ovundlile, ukuhlaziywa kwesiswebhu kungadingeka lapho kulinganiswa imiqulu emide, emincane, noma amanye ama-rotors aguquguqukayo. I-Whip isilinganiso se-deformation noma ukugoba kwe-rotor eguquguqukayo. Uma usola ukuthi kungadingeka ukuthi ulinganise isiswebhu, hlola usizo lwethu lobuchwepheshe futhi sizonquma ukuthi ngabe inkomba yesiswebhu iyadingeka yini kuhlelo lwakho lokusebenza.