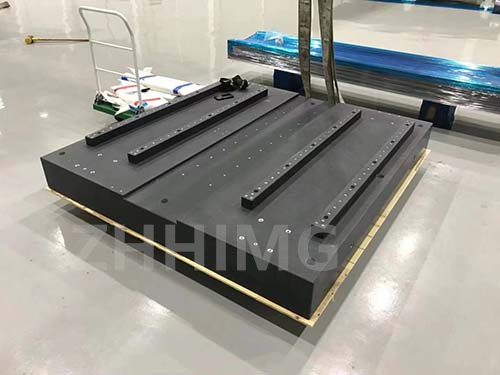

Emasimini asezingeni eliphezulu njengokukhiqiza ama-semiconductor, ukuhlolwa kokukhanya okunembile, kanye nokucutshungulwa kwezinto ezibonakalayo, ukuzinza nokunemba kwemishini kunquma ngqo ikhwalithi yomkhiqizo kanye nokusebenza kahle kokukhiqiza. Amapulatifomu okunemba kwe-granite, anokusebenza okuncibilikisayo okuphindwe kasithupha kunensimbi ephonswe, aba yintandokazi entsha embonini. Yiziphi izindinganiso ezingenakuphikiswa ezingemuva kwale nzuzo yokusebenza? Ake sihlole ndawonye izinzuzo eziyinhloko zokukhetha amapulatifomu okunemba kwe-granite.

1. Isiqinisekiso sokunemba okuphelele, amaphutha amancane awaseyona inkinga

Esikhathini sokukhiqizwa kwe-nanoscale, noma yikuphi ukudlidliza okuncane kungaholela ekukhuculweni komkhiqizo. Lapho isisekelo sensimbi ecijile sibhekene nokudlidliza okubangelwa ukusebenza kwemishini noma ukuphazamiseka kwendawo yangaphandle, ngenxa yokusebenza kwayo okunganele kokudambisa, amandla okudlidliza kunzima ukuwaqeda ngokushesha, okuholela ekushintsheni noma ekunyakaziseni kwezingxenye ezibalulekile zemishini. Ipulatifomu yokunemba kwe-granite, enezici zayo ezivelele zokudambisa, ingaguqula amandla okudlidliza abe amandla okushisa okusatshalaliswa ngokushesha, icindezele ngempumelelo ukudluliselwa kanye nokwandiswa kokudlidliza.

Thatha umshini we-semiconductor photolithography njengesibonelo. Ngemva kokusebenzisa ipulatifomu yokucacisa i-granite, ubukhulu bokudlidliza belensi bunciphe kusuka ku-±8μm kuya ku-±1.3μm, kunciphisa iphutha lobubanzi bomugqa wephethini ye-chip ngo-75% futhi kuthuthukisa kakhulu ukunemba kokukhiqiza kwe-chip. Ekuhlolweni kokucaca kokukhanya, kungaqinisekisa ukuthi ilensi yokucaca yethuluzi lokuhlola ihlala izinzile, igweme ukufiphala kwesithombe kanye nokuphambuka kwedatha okubangelwa ukudlidliza, futhi kwenze ngisho namaphutha amancane ezingeni lika-0.1μm angacasheki ndawo.

Okwesibili, inokuphila isikhathi eside kakhulu kwenkonzo futhi yehlisa izindleko zizonke

Ngaphansi kokudlidliza kanye nokushaya kwesikhathi eside nokuvama, isisekelo sensimbi ephonswe sivame ukuba nemifantu emincane ngaphakathi, okuholela ekwehleni kwamandla esakhiwo. Sidinga ukushintshwa ngemva kweminyaka emi-3 kuya kwemi-5, okungagcini nje ngokwandisa isikhathi sokungasebenzi kwemishini kodwa futhi kuletha izindleko eziphezulu zokulungisa nokufaka esikhundleni. I-Granite yakhiwe ngamakristalu amaminerali njenge-quartz ne-feldspar, ahlanganiswe eduze ngezibopho ze-ionic neze-covalent. Inesakhiwo esiqinile nesilinganayo futhi inokumelana nokukhathala okunamandla.

Ngisho nangemva kwemijikelezo yokudlidliza eyizinkulungwane ezingamashumi, ipulatifomu yokucacisa i-granite isakwazi ukugcina izakhiwo zomzimba nezikagesi ezizinzile, futhi impilo yayo yesevisi ingaba ngaphezu kokuphindwe kathathu kunesisekelo sensimbi ephonswe ngensimbi. Izibalo ezivela ebhizinisini elithile lokukhiqiza amathuluzi okucacisa zibonisa ukuthi ngemva kokusebenzisa amapulatifomu okucacisa i-granite, imvamisa yokugcinwa kwemishini yehle ngo-60%, kanti isilinganiso sezindleko zonyaka sidlula isigidi esisodwa sama-yuan.

Okwesithathu. Ukuzivumelanisa nezimo kwemvelo okuhle kakhulu, ukuphatha izimo zokusebenza eziyinkimbinkimbi kalula

Endaweni yokukhiqiza yangempela, izici ezifana nokushintsha kwezinga lokushisa, ukuphazamiseka kwe-electromagnetic, kanye nokugqwala kwamakhemikhali konke kungathinta ukusebenza kwemishini. Isisekelo sensimbi ecijile sinomthamo ophezulu wokwanda kokushisa futhi sithambekele ekushintsheni kobukhulu ngaphansi kokushintshashintsha kwezinga lokushisa, okubuye kuthinte ukunemba kwemishini. Okwamanje, simelana nokugqwala okubi futhi sithambekele ekugqwaleni nasekuguquguqukeni ngaphansi kokuguguleka kwezinto zamakhemikhali.

Amapulatifomu okunemba kwe-granite ane-coefficient ephansi kakhulu yokwanda kokushisa (i-1/20 kuphela yensimbi ephonswe), engamelana ngempumelelo nethonya elilethwa ukushintsha kwezinga lokushisa. Inezakhiwo zamakhemikhali ezizinzile futhi ayisabelani nezinto ezine-asidi noma ze-alkaline, futhi ingasebenza ngokuzinzile ezindaweni eziyinkimbinkimbi njengezindawo zokusebenzela ze-semiconductor kanye nama-laboratory amakhemikhali. Ngaphezu kwalokho, i-granite ayiqhubi futhi ayisebenzi ku-magnetic, futhi ayithintwa ukuphazamiseka kwe-electromagnetic, okuqinisekisa ukuzinza kokusebenza kwemishini.

Okwesine, ukusebenza kwemboni kuqinisekisile ukuthi kusiza ukuncintisana kwamabhizinisi ukuthi kuqhubekele phambili

Imikhuba yamabhizinisi amaningi ahamba phambili ezimbonini ezahlukahlukene ibonise ngokugcwele inani lamapulatifomu okunemba kwe-granite. Ngemva kokuba imboni enkulu yomhlaba wonke ye-semiconductor ithathe indawo yepulatifomu yokunemba kwe-granite, izinga lokukhiqiza ama-chip landa lisuka ku-78% laya ku-92%, futhi amandla okukhiqiza akhuphuka ngo-30%. Ngemva kokuba umenzi wezinsimbi zokukhanya eziphezulu amukele le pulatifomu, ukunemba kokutholwa kwemikhiqizo yakhe kwafinyelela ezingeni elihamba phambili embonini futhi yawina ama-oda amaningi emhlabeni jikelele.

Emncintiswaneni wanamuhla okhula ngamandla ekukhiqizeni ngokunemba, ukukhetha amapulatifomu okunemba nge-granite akugcini nje ngokuthuthukisa ukusebenza kwemishini yokukhiqiza, kodwa futhi kuyisinqumo esibalulekile samabhizinisi sokuthuthukisa ikhwalithi yomkhiqizo, ukunciphisa izindleko nokuthuthukisa ukuncintisana emakethe. Ngokuthuthuka okuqhubekayo kobuchwepheshe, amapulatifomu okunemba nge-granite nakanjani azodlala indima ebalulekile emikhakheni eminingi, ekhuthaza imboni ukuthi ithuthukele ekuqondeni okuphezulu kanye nokusebenza kahle okuphezulu.

Isikhathi sokuthunyelwe: Meyi-14-2025