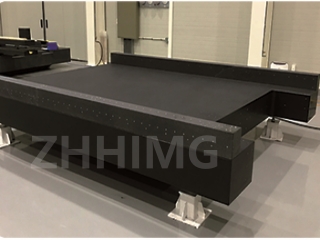

Emkhakheni wokulawula ukunyakaza okunembile kakhulu, imodyuli yokunyakaza okunembile kakhulu yokuntanta emoyeni isibe yisinqumo esifanele ezimweni eziningi zokukhiqiza ezisezingeni eliphezulu kanye nocwaningo lwesayensi ngenxa yezici zayo zokunyakaza ezingenakho ukungqubuzana kanye nokunemba okuphezulu. Ukwethulwa kwesisekelo sokunemba kwe-granite ukufaka amandla aqinile ukuze kuthuthukiswe ukusebenza kwayo, kodwa inhlanganisela yakho kokubili ayiphelele.

Okokuqala, izinzuzo ezibalulekile

Ukuqina Okuhle Kakhulu: I-Granite ngemva kwezigidi zeminyaka yezinguquko zejiyoloji, isakhiwo sangaphakathi siminyene futhi sifana, ikakhulukazi yi-quartz, i-feldspar kanye nezinye izimbiwa ezihlanganiswe eduze. Lesi sakhiwo esiyingqayizivele sinikeza isisekelo se-granite ukuzinza okuhle kakhulu. Lapho sibhekene nokuphazamiseka kwangaphandle, njengokudlidliza okubangelwa ukusebenza kwemishini emikhulu ezungezile kanye nokuguquguquka kwezinga lokushisa elizungezile, isisekelo se-granite singavimba futhi sinciphise ngempumelelo. Eshabhu lokukhiqiza ama-chip kagesi, amathuluzi omshini kanye neminye imishini isebenza njalo, kanti isisekelo se-granite singanciphisa ubukhulu bokudlidliza bemojuli yokunyakaza eqondile kakhulu edluliselwa emoyeni nge-float engaphezu kuka-80%, kuqinisekiswe ukunyakaza okubushelelezi kwemojuli, kuhlinzeke isisekelo esizinzile sezinqubo ezinembile kakhulu njenge-lithography kanye nokuqopha enkambisweni yokukhiqiza ama-chip, futhi kuthuthukise kakhulu isivuno sokukhiqiza ama-chip.

Ukugcinwa kokunemba okuphezulu kakhulu: Imojula yokunyakaza okunembile kakhulu kwe-air float idinga ukunemba okuphezulu kakhulu, futhi inzuzo ye-coefficient yokwanda okuphansi kwesisekelo se-granite idlala indima ebalulekile kulokhu. I-coefficient yokwanda kokushisa kwe-granite ejwayelekile ingu-5-7 × 10⁻⁶/℃, okuphansi kakhulu kunezinto ezivamile zensimbi. Lapho izinga lokushisa lishintsha, usayizi wesisekelo ushintsha kancane kakhulu. Emkhakheni wezinkanyezi, imojula yokunyakaza okunembile kakhulu kwe-air float yokulungiswa kahle kwelensi ye-telescope, enesisekelo se-granite, ingaqinisekisa ukuthi ukunemba kokubekwa kwelensi kugcinwa ezingeni le-sub-micron noma ngabe umehluko wokushisa phakathi kwemini nobusuku mkhulu, okusiza izazi zezinkanyezi ukuthi zibone ngokucacile izidalwa zasezulwini ezikude.

Ukumelana okuhle nokuguguleka kanye nokuphila isikhathi eside: Nakuba imodyuli yokunyakaza okuqondile okuntantayo emoyeni inciphisa ukungqubuzana okuqondile ngesikhathi sokusebenza, kusenezinga elithile lengozi yokuguguleka ekusetshenzisweni kwesikhathi eside. Ubulukhuni begranite buphezulu, ubulukhuni be-Mohs bungafinyelela ku-6-7, ukumelana okuqinile kokuguguleka. Elabhorethri yesayensi yezinto zokwakha, imodyuli yokunyakaza okuqondile okuntantayo emoyeni esetshenziswa njalo, isisekelo segranite singamelana ngempumelelo nokungqubuzana kwesilayida sokuntanta emoyeni, uma kuqhathaniswa nesisekelo sensimbi esivamile, singandisa umjikelezo wokugcinwa kwemodyuli ngaphezu kuka-50%, sinciphise izindleko zokugcinwa kwemishini, futhi siqinisekise ukuqhubeka komsebenzi wocwaningo lwesayensi.

Okwesibili, kukhona ukushiyeka

Izindleko eziphezulu: Izindleko zokuthengwa kwezinto zokusetshenziswa zegranite ezisezingeni eliphezulu ziphezulu, futhi ukumbiwa kwayo, ukuthuthwa kanye nokucubungula kuyinkimbinkimbi kakhulu, kudinga imishini nobuchwepheshe bochwepheshe. Kusukela ekumbeni i-ore yegranite efanele kuya ekucutshungulweni kuya esisekelweni semoduli yomoya entantayo enembile kakhulu ehlangabezana nezidingo zokunemba okuphezulu, kuhilela izinqubo eziningi ezinhle, njengokusika okunembile kakhulu, ukugaya, ukupholisha, njll., okwenza izindleko zokukhiqiza zesisekelo sokunemba kwegranite zikhuphuke kakhulu. Uma kuqhathaniswa nezinye izinto ezifana nensimbi, izindleko zingaba ngaphezulu kaningana noma ngaphezulu, okunciphisa ukusetshenziswa kwayo okukhulu ngezinga elithile, ikakhulukazi kumabhizinisi amancane noma izikhungo zocwaningo lwesayensi ezinezabelomali ezilinganiselwe.

Isisindo esinzima: Ubuningi be-granite bukhulu kakhulu, cishe buyi-2.6-3.1g /cm³, okuholela esisekelweni esinzima sokunemba kwe-granite. Enqubweni yokufaka nokuphatha imishini, kudingeka imishini yokuphakamisa yobungcweti kanye nabasebenzi, okwandisa ubunzima bezindleko zokufaka nezokuthutha. Kwezinye izimo ezidinga ukuguquguquka okuphezulu kokuhlelwa kwendawo yemishini, isisekelo esinzima siphinde sinciphise ukunyakaza okulula kanye nokufakwa kabusha kwemojuli yokunyakaza enembile kakhulu ye-air float, okuthinta ukusebenza kahle kanye nokuzivumelanisa nezimo kwemishini.

Kunzima ukukucubungula: i-granite inobulukhuni obukhulu kanye nokuqhekeka, kanti izidingo zemishini yokucubungula kanye nenqubo ziqinile kakhulu. Enkambisweni yokucubungula, kulula ukuba nemifantu, imifantu kanye nezinye iziphambeko, futhi kunzima ukuqinisekisa ukunemba kokucubungula kanye nekhwalithi yobuso. Ukuze kufezwe ukuthamba nokunemba okuphezulu okudingekayo yi-module yokunyakaza enembile kakhulu ye-air float, kudingeka ukuhlolwa nokulungiswa okuningi ngesikhathi senqubo yokucubungula, futhi umjikelezo wokucubungula mude futhi izinga lokwenqatshwa liphezulu, okwandisa kakhulu izindleko zokukhiqiza kanye nezindleko zesikhathi.

Imojula yokunyakaza enembile kakhulu enesisekelo sokunemba kwe-granite inezinzuzo ezivelele ekuzinzeni nasekunembileni, okufanelekela amasimu aphezulu anezidingo zokunemba okuphezulu, kodwa ibhodi elifushane njengezindleko, isisindo kanye nobunzima bokucubungula nalo lidinga ukucatshangelwa ngokuphelele ezisetshenzisweni ezisebenzayo, futhi kwenziwa ukukhetha okunengqondo ngemva kokulinganisa izinzuzo kanye nokungalungi.

Isikhathi sokuthunyelwe: Ephreli-08-2025