.

Enkathini yanamuhla yentuthuko esheshayo kwezobuchwepheshe, imishini yokuhlola amaphaneli angu-8K ibalulekile ekuqinisekiseni ikhwalithi ephezulu yezikrini zokubonisa. Uma imishini enjalo isebenza, inezidingo eziphakeme kakhulu zokuzinza kwendawo yokuthola. Noma yikuphi ukudlidliza okuncane kungabangela ukuphambuka emiphumeleni yokuthola. I-granite, ngenxa yezakhiwo zayo eziyingqayizivele zomzimba, isibe yinto efanelekile ohlelweni lokulwa nokudlidliza kwemishini yokuhlola amaphaneli angu-8K.

Izinzuzo eziphawulekayo ze-granite

I-granite iqinile ngokwesakhiwo futhi inokuqina okuphezulu kakhulu. Isakhiwo sayo sangaphakathi sincane, futhi amandla okubopha phakathi kwamakristalu aqinile, angamelana ngempumelelo nomthelela kanye nokuguquguquka kwamandla angaphandle. Lokhu kuqina okuphezulu kwenza i-granite ingabi namathuba amaningi okuguquguquka okukhulu lapho ithwala isisindo semishini futhi ibhekene nokudlidliza okungenzeka, okunikeza ukwesekwa okuqinile kwesisekelo semishini yokuthola.

Okwamanje, i-granite nayo inezakhiwo ezinhle kakhulu zokudambisa. Ukudambisa kubhekisela emandleni ento okusebenzisa amandla nokunciphisa ubukhulu bokudlidliza ngesikhathi senqubo yayo yokudlidliza. Izici zokudambisa ze-granite zivela esakhiweni sayo samaminerali sangaphakathi esiyinkimbinkimbi kanye nama-pores amancane. Lapho ukudlidliza kudluliselwa ku-granite, lezi zakhiwo nama-pores zingaguqula amandla okudlidliza abe ezinye izinhlobo zamandla njengamandla okushisa, ngaleyo ndlela zinciphise ngokushesha ukudlidliza. Uma kuqhathaniswa nezinye izinto, i-granite inomphumela wokudambisa obaluleke kakhulu futhi inganciphisa kakhulu umthelela wokudlidliza kwangaphandle emishinini yokuthola.

Izindlela zokusebenzisa i-granite ezinhlelweni zokulwa nokudlidliza

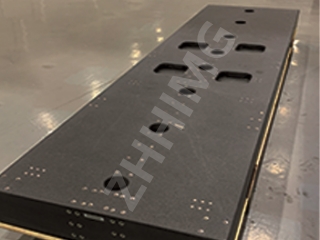

Njengesisekelo semishini

Ukwenza isisekelo semishini yokuhlola nge-granite kuyindlela evamile yokuvimbela ukudlidliza. Ngokucutshungulwa ngokucophelela, ukuthamba komphezulu wesisekelo se-granite kufinyelela izinga eliphakeme kakhulu lokunemba, okuqinisekisa ukuthi imishini ingafakwa kahle ngemva kokufakwa. Ngenxa ye-granite

Isisekelo singahlukanisa ngempumelelo ukudlidliza okudluliswa phansi, sinciphise ukuphazamiseka kokudlidliza ezingxenyeni ezinembile ngaphakathi kwemishini, futhi senze inqubo yokuthola izinze futhi ithembeke kakhudlwana. Isibonelo, kweminye imishini yokuhlola amaphaneli e-8K ephezulu, ukusetshenziswa kwezisekelo ze-granite ezingamasentimitha ambalwa ubukhulu, kuhlanganiswe namasu okufaka anembile, kunganciphisa umthelela wokudlidliza komhlaba kube sezingeni elicishe lilingane, ngaleyo ndlela kuqinisekiswe ukunemba nokuphindeka kwemiphumela yokuhlola.

Isetshenziswa kanye nezingxenye zokuhlukanisa ukudlidliza

Ukuze kuthuthukiswe umphumela wokulwa nokudlidliza, i-granite ivame ukusebenza ngokubambisana nezingxenye ezahlukahlukene zokuhlukanisa ukudlidliza. Ukufaka ama-raber vibration isolation pads ngaphansi kwesisekelo se-granite kuyindlela elula nephumelelayo. I-raber ine-elasticity enhle kakhulu kanye nezakhiwo zokudambisa, ekwazi ukumunca nokuvimbela amandla okudlidliza avela emhlabathini. Lapho ukudlidliza kudluliselwa ku-raber vibration isolation pad, ukuguquguquka kwayo okunwebekayo kuguqula kancane amandla okudlidliza abe amandla okushisa ngaphakathi kwe-raber. Okwamanje, umphumela wokudambisa we-raber uphinde ucindezele ukudluliselwa okuqhubekayo kokudlidliza. Ngale ndlela, ngemuva kokuhlukaniswa kokuqala kokudlidliza ngama-raber vibration isolation pads, ukudlidliza okuncane okusele kuncishiswa kakhulu yi-granite base, okuthuthukisa kakhulu ukusebenza kohlelo lonke lokulwa nokudlidliza.

Ngaphezu kwalokho, inhlanganisela yesistimu yokuhlukanisa ukudlidliza komoya kanye ne-granite nayo isetshenziswe kabanzi kweminye imishini yokuthola enembayo ephezulu. Uhlelo lokuhlukanisa ukudlidliza komoya luhlukanisa ukudlidliza ngokwenza ifilimu yomoya enembayo ephezulu phakathi kwesisekelo se-granite nomhlabathi, lusebenzisa ukucindezelwa komoya. Isisekelo se-granite, esisekelwa uhlelo lokuhlukanisa umoya, cishe sisesimweni sokumiswa esingenakho ukungqubuzana futhi singahlukanisa ngempumelelo kakhulu ukudlidliza okunembayo ephansi. Le ndlela yokuhlanganisa ifaneleka kakhulu enkambisweni yokuhlola iphaneli ye-8K ezwela kakhulu ekudlidlizeni, njengesigaba sokuhlola okunembayo okuphezulu. Ingaqinisekisa ukuthi imishini yokuhlola isebenza endaweni ezinzile kakhulu futhi ifinyelele ekutholakaleni okunembile kwamaphutha amancane kuphaneli.

Isifinyezo sezinzuzo zezinhlelo zokulwa nokudlidliza ze-granite

I-Granite inezinzuzo eziningi ohlelweni lokulwa nokudlidliza lwemishini yokuhlola amaphaneli angu-8K. Ngokombono wokusebenza kahle kwezindleko, i-granite, njengezinto zemvelo, inemithombo ehlukahlukene kanye nentengo efanelekile. Uma kuqhathaniswa nezinye izinto zokwenziwa ezisezingeni eliphezulu noma amadivayisi ayinkimbinkimbi okulwa nokudlidliza, ukusebenzisa i-granite ukwakha uhlelo lokulwa nokudlidliza kungalawula ngempumelelo izindleko ngenkathi kuqinisekiswa umphumela wokulwa nokudlidliza.

Ngokuphathelene nokuqina nokuqina, ukuqina okuphezulu kanye nokuqina okuhle ngokomzimba namakhemikhali kwe-granite kuyenza ikwazi ukugcina ukusebenza okuzinzile isikhathi eside. Ayithinteki kalula yizici zemvelo ezifana nokushisa nomswakama ukuze ishintshe noma inciphise ukusebenza kwayo, futhi inganikeza isiqinisekiso sokulwa nokudlidliza esihlala isikhathi eside nesithembekile semishini yokuthola. Ngisho nangesikhathi sokusetshenziswa isikhathi eside nangesivinini esikhulu, uhlelo lokulwa nokudlidliza lwe-granite lungaqhubeka nokusebenza okuhle kakhulu kokulwa nokudlidliza, kuncishiswe imvamisa yokwehluleka kwemishini nokugcinwa okubangelwa izinkinga zokudlidliza, futhi kuthuthukiswe impilo yesevisi iyonke kanye nokusebenza kahle kwemishini.

Ekuphetheni, i-granite, enezakhiwo zayo ezihlukile, idlala indima ebalulekile futhi engenakuphindwa ohlelweni lokulwa nokudlidliza kwemishini yokuhlola amaphaneli angu-8K, ihlinzeka ngesisekelo esiqinile nesithembekile sokuqinisekisa ukusebenza okunembile kwemishini yokuhlola kanye nemiphumela yokuhlola esezingeni eliphezulu.

Isikhathi sokuthunyelwe: Meyi-19-2025