Ezweni lanamuhla lokukhiqiza okuthuthukile, “izinsimbi ze-3D” azisabhekiseli kuphela emishinini yokulinganisa ehlanganisiwe. Leli gama manje lihlanganisa indawo ebanzi: ama-laser tracker, ama-scanner okukhanya okuhlelekile, ama-photogrammetry rigs, amaseli e-metrology amaningi, ngisho nezinhlelo zokubona eziqhutshwa yi-AI ezisetshenziswa kukho konke kusukela ekuhlanganisweni kwezindiza kuya ekusetshenzisweni kwe-biomedical prototyping. Lawa mathuluzi athembisa isixazululo esingakaze sibonwe, isivinini, kanye nokwenza izinto ngokuzenzakalela—kodwa ukusebenza kwawo kuthembeke kuphela njengobuso obumi kuwo. Kwa-ZHHIMG, sibone amathuluzi amaningi e-3D aphezulu kakhulu engasebenzi kahle hhayi ngenxa ye-optics noma isofthiwe enephutha, kodwa ngoba afakwe ezisekelweni ezingakwazi ukuhlangabezana nezidingo ze-metrology yokunemba kwangempela.

Isixazululo akusikho ukulinganisa okwengeziwe—kuyi-physics engcono. Futhi iminyaka engaphezu kwamashumi amabili, leyo physics ibilokhu ikhomba njalo ezintweni ezisetshenziswayo: i-granite. Hhayi njenge-relic yesikhathi esidlule, kodwa njengesisekelo esingcono ngokwesayensi sanoma yiluphi uhlelo lapho ama-micron ebaluleke khona. Kungakhathaliseki ukuthi uskena i-turbine blade enesikhala samaphuzu esingaphansi kuka-10µm noma uhlela izingalo zerobhothi emsebenzini wokusebenza we-digital twin, ukuzinza kwesisekelo sakho somshini we-granite wezinsimbi ze-3D kunquma ngqo ukuthembeka kwedatha yakho.

Izinzuzo ze-granite zisekelwe ezimpahleni zomzimba ezingaguquki. I-coefficient yayo yokwanda kokushisa—ngokuvamile phakathi kuka-7 no-9 × 10⁻⁶ nge-°C—iphakathi kwezinto zobunjiniyela eziphansi kakhulu ezitholakalayo. Ngokwesimo esingokoqobo, lokhu kusho ukuthi i-granite slab engamamitha amabili izokhula noma inciphe ngaphansi kwama-microns amabili ekushintsheni okuvamile kwefektri okungu-5°C. Qhathanisa lokho nensimbi (≈12 µm) noma i-aluminium (≈60 µm), bese umehluko uba sobala. Kumathuluzi e-3D athembele ekubhekiseleni okuphelele kwendawo—njengezithrekhi ze-laser ezisetshenziswa ekuqondisweni kwamaphiko endiza—lokhu kungathathi hlangothi kokushisa akuyona into ongayikhetha; kubalulekile.

Kodwa ukuzinza kokushisa kuyingxenye yendaba. Esinye isici esibalulekile ukucindezela kokudlidliza. Izimboni zanamuhla ziyindawo enomsindo: ama-spindle e-CNC ajikeleza ku-20,000 RPM, amarobhothi ashaya ama-end stops, kanye nezinhlelo ze-HVAC zishaya phansi. Lokhu kudlidliza, okuvame ukungabonakali kubantu, kungafiphaza ama-optical scans, ku-jitter probe tips, noma kususe ama-array amaningi ezinzwa. I-Granite, enesakhiwo sayo esiqinile sekristalu, imunca futhi ihlakaze ngokwemvelo lokhu kuguquguquka kwemvamisa ephezulu kakhulu kunezinhlaka zensimbi noma amatafula ahlanganisiwe. Ukuhlolwa okuzimele kwelebhu kukhombisile ukuthi izisekelo ze-granite zinciphisa ukukhulisa i-resonant ngamaphesenti afinyelela ku-65 uma kuqhathaniswa nensimbi ephothiwe—umehluko ohumushela ngqo emafwini ahlanzekile kanye nokuphindaphindeka okuqinile.

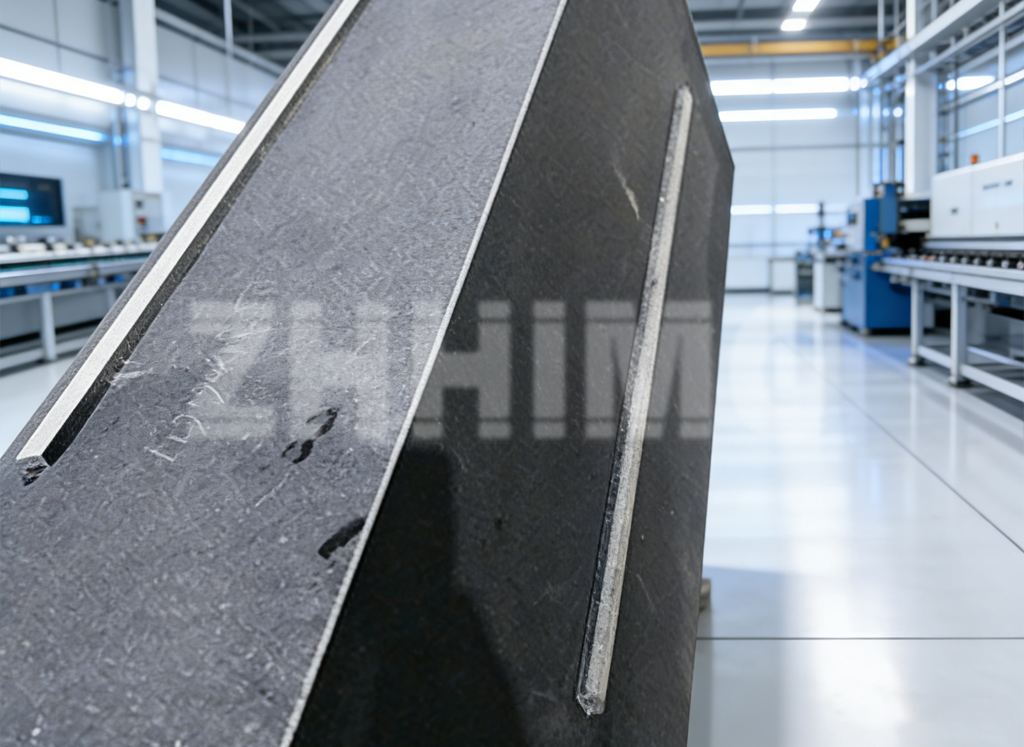

Kwa-ZHHIMG, asiphathi i-granite njengempahla.umbhede womshini wegraniteKwezinto ze-3D esizikhiqizayo kuqala ngamabhulokhi aluhlaza akhethiwe kahle—ngokuvamile ama-diabase amnyama acwebezelayo noma i-gabbro avela ezindaweni zokumba eziqinisekisiwe zaseYurophu naseNyakatho Melika ezaziwa ngokuba nama-porosity aphansi kanye nobuningi obuqhubekayo. Lawa mabhulokhi adlula izinyanga eziyi-12 kuya kwezingu-24 zokuguga kwemvelo ukuze kuncishiswe ukucindezeleka kwangaphakathi ngaphambi kokungena ehholo lethu le-metrology elilawulwa yisimo sezulu. Lapho, ochwepheshe abangochwepheshe babamba ubuso ngezandla ukuze babhekane nokuthambekela okuyisicaba ngaphakathi kwama-micron angu-2-3 ngaphezu kwebanga elingaphezu kwamamitha angu-3, bese behlanganisa izinto ezifakwe ngentambo, ama-grounding lugs, kanye ne-modular fixturing rails besebenzisa amasu agcina ubuqotho besakhiwo.

Lokhu kunakwa kwemininingwane kudlulela ngale kwesisekelo ngokwaso. Ngokuqhubekayo, amaklayenti adinga okungaphezu nje kwendawo eyisicaba—adinga izakhiwo zokusekela ezihlanganisiwe ezigcina ukuhambisana kwe-metrological kulo lonke uhlaka lwensimbi. Yingakho siye saba ngamaphayona okusetshenziswa kweizingxenye ze-granite mechanicalkwezinsimbi ze-3D, kufaka phakathi izinsimbi eziwela i-granite, izidleke ze-granite probe, izikhonkwane ze-granite encoder, ngisho namakholomu e-gantry aqiniswe yi-granite. Ngokufaka i-granite kuma-node athwala umthwalo oyinhloko, sandisa ukuzinza kokushisa nokudlidliza kwesisekelo phezulu kuya ekwakhiweni okuhambayo kwethuluzi. Iklayenti elilodwa lakamuva emkhakheni wemishini ye-semiconductor lithathe indawo yezingalo ze-carbon-fiber ngezixhumanisi ze-granite-composite ezihlanganisiwe ku-rig yabo yokulungiswa kwe-3D eyenziwe ngokwezifiso—futhi labona ukwehla kokulinganisa ngo-58% esikhathini samahora angu-8.

Yiqiniso, akuzona zonke izinhlelo zokusebenza ezidinga ama-slab agcwele e-monolithic. Ngokusethwa okuphathekayo noma kwe-modular—njengeziteshi ze-photogrammetry ezingafakwa ensimini noma amaseli okulinganisa amarobhothi ahambayo—sinikeza amathayili e-granite aqondile kanye nama-reference plate asebenza njengedathamu yendawo. Lawa ma-granite amancane aqondile ezinto ze-3D angafakwa emabhentshini okusebenzela, kuma-pedestal amarobhothi, noma ngisho nasezitezi zamagumbi okuhlanza, okuhlinzeka ngendawo yokukhosela ezinzile lapho kudingeka khona ukubhekisela kwendawo okuthembekile. Ithayili ngalinye liqinisekiswe ngokwalo ukuthi liyisicaba, liyafana, futhi liqedwe, ukuqinisekisa ukulandeleka kwezindinganiso ze-ISO 10360.

Kuhle ukubhekana nombono ovamile oyiphutha: ukuthi i-granite inzima, iyaphuka, noma isiphelelwe yisikhathi. Eqinisweni, izinhlelo zesimanje zokuphatha nokufaka zenza amapulatifomu e-granite aphephe futhi kube lula ukuwafaka kunanini ngaphambili. Futhi nakuba i-granite iminyene, ukuqina kwayo akunakuqhathaniswa—ukufakwa kwethu okudala, kusukela ekuqaleni kwawo-2000, kuhlala kusensimini yansuku zonke ngaphandle kokuwohloka kokusebenza. Ngokungafani nensimbi ependiwe eqhekeka noma ehlanganisiwe enyakazayo ngaphansi komthwalo, i-granite iyathuthuka njengoba ikhula, ithuthukisa indawo ebushelelezi ngokusebenzisa ngobumnene. Ayidingi ukumbozwa, ayidingi ukulungiswa ngaphandle kokuhlanza okuvamile, futhi ayidingi ukulinganiswa kabusha ngenxa yokukhathala kwezinto ezibonakalayo.

Ngaphezu kwalokho, ukusimama kuyingxenye yale ndlela. I-granite ingokwemvelo ngokuphelele, ingaphinde isetshenziswe ngokugcwele, futhi itholakala ngomthelela omncane kakhulu emvelweni uma imbiwa ngendlela efanele. Enkathini lapho abakhiqizi behlola khona umjikelezo wokuphila kwempahla ngayinye, isisekelo se-granite simelela ukutshalwa kwezimali kwesikhathi eside—hhayi nje ngokunemba, kodwa nangobunjiniyela obunomthwalo wemfanelo.

Siyaziqhenya ngokusobala. Yonke ipulatifomu ye-ZHHIMG ithunyelwa nombiko ogcwele we-metrology—kufaka phakathi amamephu okuthamba, ama-thermal drift curves, kanye namaphrofayili okuphendula ngokudlidliza—ukuze onjiniyela bakwazi ukuqinisekisa ukufaneleka kwesicelo sabo esithile. Asithembeli ezicini “ezijwayelekile”; sishicilela idatha yangempela yokuhlola ngoba siyazi ukuthi ku-metrology enembile, ukuqagela kubiza imali.

Lokhu kuqina kusenze saba nobudlelwano nabaholi kuzo zonke izimboni lapho ukwehluleka kungeyona inketho: ama-OEM ezindiza aqinisekisa izingxenye ze-fuselage, izinkampani zemishini yezokwelapha ezihlola amajiyometri okufakelwa, kanye nabakhiqizi bamabhethri e-EV abavumelanisa amathuluzi e-gigafactory. Omunye umhlinzeki wezimoto waseJalimane muva nje uhlanganise iziteshi ezintathu zokuhlola ezindala zaba yiseli elilodwa le-ZHHIMG-based multi-sensor cell eline-tactile probes kanye ne-blue-light 3D scanners—konke okubhekiselwe ku-granite datum efanayo. Umphumela? Ukuxhumana kokulinganisa kuthuthuke kusuka ku-±12 µm kuya ku-±3.5 µm, futhi isikhathi somjikelezo sehle ngo-45%.

Ngakho-ke njengoba uhlola ukusetshenziswa kwakho okulandelayo kwe-metrology, zibuze: ingabe ukusethwa kwakho kwamanje kwakhelwe esisekelweni esenzelwe iqiniso—noma ukuvumelana? Uma amathuluzi akho e-3D edinga ukulinganiswa kabusha njalo, uma ukuphambuka kwakho kokuskena-kuya-ku-CAD kushintshashintsha ngokungalindelekile, noma uma isabelomali sakho sokungaqiniseki siqhubeka nokukhula, inkinga ingase ingabi sezinzwa zakho, kodwa kulokho ezikusekelayo.

Kwa-ZHHIMG, sikholelwa ukuthi ukunemba kufanele kube yinto engokwemvelo, hhayi ekhokhelwayo. Vakashelawww.zhhimg.comukuhlola ukuthi i-granite yethu enembile yezinsimbi ze-3D, ehlanganiswe nezingxenye ze-granite ezakhiwe ngenhloso zezinsimbi ze-3D, isiza onjiniyela emhlabeni wonke ukuguqula idatha yokulinganisa ibe ukuzethemba okusebenzayo. Ngoba lapho yonke i-micron ibalwa, akukho okunye okuthatha indawo yomhlabathi oqinile.

Isikhathi sokuthunyelwe: Jan-05-2026