Njenge "sisekelo sesisekelo" sokulinganisa nokukhiqiza ngokunembile, amapulatifomu e-granite okulinganisa, anokuthamba kwawo okumangalisayo kanye nokuqina kokuhambisana, angene emikhakheni ebalulekile njengokukhiqiza ngokunembile, ucwaningo lwezindiza, izimoto, kanye ne-metrology. Inani lawo eliyinhloko lisekuhlinzekeni indawo yokubhekisela "engenaphutha" yezimo ezahlukahlukene zokuhlola okunembile kanye nokuhlanganiswa, ezivumelana nezidingo zochungechunge lonke lokuhlinzeka, kusukela ekusetshenzisweni kwemishini yendabuko kuya ezinhlelweni ze-metrology ezihlakaniphile.

Izimo Zokusebenza Eziyinhloko Nokuhambisana Kwemboni

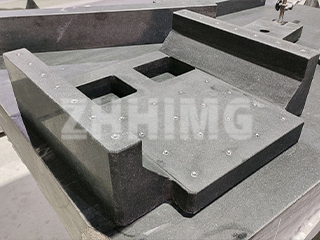

Ekukhiqizeni ngokunemba, amapulatifomu e-granite “angamasango” okulawula ikhwalithi: ukulinganiswa kokunemba kwejiyometri kwamathuluzi omshini we-CNC, ukuhlolwa kwezinga le-micron kokuqina kwesikhunta, kanye nokuqinisekiswa kobukhulu bezingxenye eziphrintiwe nge-3D konke kuncike endaweni eqondile yokubhekisela abayinikezayo. Isibonelo, ekukhiqizeni isikhunta, ipulatifomu, ehlanganiswe nesilinganiso sokuphakama, ingalinganisa ngokunembile ukujula kwesikhala, iqinisekise ukuhambisana kwezingxenye ezibunjiwe nemidwebo yomklamo.

Ukuphishekela okujulile kokunemba kwemboni yezindiza kwenze amapulatifomu e-granite aba uhlelo lokusebenza olusezingeni eliphezulu. Ukuhlolwa kwe-contour ebusweni bama-turbine blades, ukulinganiswa kokubekezelelana kwamabhulokhi enjini, ngisho nokuhlanganiswa nokubekwa kwezingxenye zesathelayithi konke kudinga amapulatifomu njengamapuleti okulinganisa izindiza ukuze kuhlinzekwe izinkomba zobuso ezisezingeni le-submicron. Imininingwane evela enkampanini yokukhiqiza izindiza ikhombisa ukuthi ukusebenzisa ipulatifomu ye-granite yebanga elingu-00 kunciphisa amaphutha okulinganisa ezingxenyeni zenjini ngo-15%, okuthuthukisa ngqo ukuthembeka komshini jikelele.

Ekukhiqizweni okukhulu kwemboni yezimoto, amapulatifomu asebenza “njengabaqaphi bekhwalithi”: ukulinganisa ukuvuleka kwegiya le-meshing kuma-transmission nokuqinisekisa ukufana kobukhulu bama-brake pads. Ngokuhambisana nemishini efana nama-optical comparator, avumela ukuhlolwa kwekhwalithi okuphumelelayo kwamaqoqo ezingxenye. Inkampani ehamba phambili yezimoto yembule ukuthi ukusebenzisa ipulatifomu ye-granite ene-T-slots emgqeni wayo wokukhiqiza kukhulise ukusebenza kahle kwe-component clamping ngo-30% futhi kwathuthukisa ukuzinza kwedatha yokuhlola ngo-22%.

Kuma-laboratories e-metrology, amapulatifomu e-granite abeka amazinga ajwayelekile. Njengesisekelo se-granite se-CMM semishini yokulinganisa ehlanganisiwe (ama-CMM), ahlinzeka ngendiza yokubhekisela yokulinganisa ubude, okuqinisekisa ukunemba kokulinganisa kwamabhulokhi e-gauge, ama-micrometer, nezinye izinsimbi zokulinganisa. Ama-laboratories e-metrology ahamba phambili emhlabeni wonke, njenge-NIST (National Institute of Standards and Technology), asekela izinhlelo zawo zokubhekisela ubude kumapulatifomu e-granite anembe kakhulu. Ukusatshalaliswa Kwemakethe Yomhlaba Wonke kanye Nezintandokazi Zesifunda

Isidingo semakethe ezifundeni ezahlukene sibonisa umehluko omkhulu, okubonisa ukuhlanganiswa okujulile kwezindinganiso zemboni kanye nezimo zohlelo lokusebenza:

Isimo Semakethe Yomhlaba Wonke

INyakatho Melika (32%): Iqhutshwa kakhulu yizimboni zezindiza kanye neze-semiconductor, igcizelela ukunemba okuphezulu kanye nokuhambisana nesitifiketi, njengokulandelela kwe-NIST kanye nokugunyazwa kwelebhu ye-ISO 17025. Izicelo ezijwayelekile zifaka phakathi ukulinganiswa kwephrofayili yama-blade enjini yezindiza.

IYurophu (38%): Ibuswa yimishini enembile kanye nemikhakha yokukhiqiza izimoto, ikhetha amazinga e-DIN kanye nezinto ezinobungani nemvelo, njenge-granite ekhipha ugesi omncane ehambisana ne-DIN 876. I-Bosch Group, inkampani enkulu yezimoto yaseJalimane, icacisa le nkundla yokulinganisa izinzwa zokushayela ezizimele.

I-Asia-Pacific (CAGR 7.5%): I-China ne-India yizinjini eziyinhloko zokukhula, eziqhutshwa yisidingo esikhulayo ekukhiqizweni kwezinto zikagesi (njengokupakisha nokuhlola ama-chip) kanye nezimoto ezintsha zamandla. Abakhiqizi bendawo basebenzisa izinzuzo zezindleko ukuze babambe izimakethe ezisezingeni eliphansi neliphakathi ngenkathi besheshisa isitifiketi se-ISO 17025 ukuze badlule ezithiyo emakethe ephezulu.

Kusukela ekuzivumelaniseni okusebenzayo kuya ekwenzeni ngokwezifiso zesifunda, ipulatifomu ye-granite yokulinganisa iqhuba i-drive enamasondo amabili "yomklamo osuselwe esimweni + isitifiketi esijwayelekile," iba yisikhungo esiyinhloko esixhumanisa ukukhiqizwa kokunemba nokulawulwa kwekhwalithi. Kungakhathaliseki ukuthi isebenza njengesisekelo se-granite se-CMM ukusekela imishini yokulinganisa ephezulu noma njengepuleti lokulinganisa izindiza ukuqinisekisa ukuphepha kwezindiza, "inani layo lokulinganisa" kugagasi le-Industry 4.0 lizoqhubeka nokuvelela.

Isikhathi sokuthunyelwe: Septhemba 11-2025