Ezweni elizenzakalelayo kakhulu lobunjiniyela obunembile kakhulu, lapho izinhlelo zokulandelela i-laser eziyinkimbinkimbi kanye nama-algorithms ayinkimbinkimbi ephatha ukulawula ukunyakaza, kungase kubonakale kungqubuzana ukuthi ukunemba okuphelele kwejometri kusathembele kumathuluzi asukela ezinsukwini zokuqala ze-metrology. Kodwa-ke, njengoba imboni ingena ngokujulile ezizindeni ze-sub-micron kanye ne-nanometer, indima eyisisekelo yamathuluzi e-precision granite—ikakhulukazi i-granite straight ruler enokunemba kwebanga le-00, isikwele se-granite, kanye ne-isikwele se-granite tri—akugcini nje ngokusekelwa, kodwa kuyakhuliswa. Lawa mathuluzi angaguquki, angenzi lutho ayizindawo zokubhekisela ezingaguquki eziqinisekisa ukusebenza kwezinhlelo ezishintshashintshayo ezithuthuke kakhulu.

Isidingo sala mathuluzi okubhekisela e-granite sivela esimisweni esiyisisekelo somzimba: ukuzinza kokushisa nokwemishini. Noma yimuphi umshini owenzelwe ukunemba okuphezulu kumele uqinisekise ukuthi izindiza zawo zokulinganisa kanye nokuhamba okuqondile kuyiqiniso, kuqondile, futhi kuqondile. Lapho ukukhiqiza kwanamuhla kudinga ukuzinza kobukhulu obungathinteki ukushintshashintsha kwezinga lokushisa noma ukudlidliza kwangaphandle, izinto ezifana nensimbi noma insimbi ephonswe—ene-coefficient ephezulu yokwanda kokushisa (CTE) kanye nomthamo ophansi wokudambisa—ziyahluleka ukuhlolwa.

Ngakolunye uhlangothi, i-granite inikeza indawo efanelekile yokuzinza. I-CTE yayo ephansi isho ukuthi izinguquko zokushisa zibangela ukuzulazula okuncane kobukhulu, okwenza kube yinto efanelekile yokuchaza indiza yokubhekisela ehlala ibikezelwa. Ngaphezu kwalokho, ikhono layo elingokwemvelo lokudambisa okuphezulu limunca ukudlidliza ngokushesha, livimbele i-chatter kanye ne-resonance ezosakazwa amathuluzi ensimbi, okubaluleke kakhulu emalabhorethri e-metrology nasezindaweni zokuhlangana lapho umsindo ozungezile uyinselele eqhubekayo.

Isisekelo Sokulingana: Umbusi Oqondile We-Granite Onokunemba Kwebanga 00

Ukulinganiswa kokuqonda kuyisisekelo se-metrology yobukhulu. Yonke inkombandlela eqondile, ukuthwala komoya, kanye ne-CMM axis kuncike endleleni yokunyakaza eqondile eqinisekisiwe. Ngezicelo ezidinga ngempela, i-granite straight ruler enokunemba kwebanga 00 iba yigunya eliphelele.

Ukuqokwa kweBanga 00 (noma iBanga Eliphezulu elilinganayo) kusho izinga eliphakeme kakhulu lokunemba elingatholakala ngaphandle kwamalebhu kazwelonke ezindinganiso. Leli zinga lokunemba lidinga ukuthi ukuphambuka kokuqonda kulo lonke uhlangothi lokusebenza lombusi kumele kulinganiswe ngezingxenyana ze-micron. Ukufinyelela leli zinga lokuthembeka kwejometri akudingi nje kuphela izinto ezifanele kodwa futhi nenqubo yokukhiqiza elawulwa ngokucophelela.

Inqubo yokukhiqiza kumele ilandele izincazelo eziqinile zamazwe ngamazwe, njengezindinganiso ze-DIN, JIS, ASME, noma ze-GB. Lezi zindinganiso zomhlaba wonke zilawula izinqubo zokuhlola, izimo zemvelo, kanye nokubekezelelana okwamukelekayo. Kubakhiqizi abakhonza amakhasimende omhlaba wonke—kusukela ezinkampanini ze-semiconductor zaseJapan kuya kubakhi bamathuluzi omshini baseJalimane—ikhono lokuqinisekisa i-granite straight ruler ngokumelene nezindinganiso eziningi ngesikhathi esisodwa luyisibonakaliso sobuchwepheshe kanye nokuqina kwesistimu yekhwalithi. Umsebenzi walo mbusi ulula: ukuhlinzeka ngomugqa ongasebenzi, ongaguquki lapho iphutha lokuqondisa le-dynamic machine axis lingafakwa khona futhi linxephezelwe.

Ukuchaza Ukuma Okuqondile: I-Granite Square kanye ne-Granite Tri Square

Nakuba ukuqondisa kunquma ikhwalithi yokunyakaza okuqondile, ukuthambekela (noma isikwele) kunquma i-geometry yokusebenza komshini. Ukuhlangana kwama-axes okunyakaza (njenge-axes ka-X no-Y, noma i-axis ka-Z maqondana nendiza eyisisekelo) kumele kube ngu-90° ngqo. Noma yikuphi ukuphambuka lapha, okwaziwa ngokuthi iphutha lesikwele, kuhumushela ngqo ephutheni lesimo, okwandisa ubunzima bokufeza ukubekwa kwesici okunembile.

Isikwele segranite kanye nesikwele segranite tri yizona zinto eziyinhloko ezisetshenziswa ukuqinisekisa le engela eyisisekelo.

-

Isikwele segranite sivame ukusetshenziselwa ukuqinisekisa ubungako bezingqimba zomshini uma kuqhathaniswa nepuleti lokubhekisela noma ukuqinisekisa ukugoba kwezingxenye ngesikhathi sokuhlanganiswa. I-geometry yayo eqinile enomumo we-L iqinisekisa ukuthi ubuso obubili obusebenzayo bugcinwa nge-engeli engu-90° eqinisekisiwe.

-

Isikwele se-granite tri (noma isikwele esikhulu) sinikeza ukucushwa kwejometri okuhlukile okunobuso obuthathu, okuvumela ukuhlolwa okuphelele kwejometri ye-cubic ngaphakathi kohlaka lomshini. Lokhu kucushwa kuwusizo kakhulu ekumiseni imingcele ye-cubic yama-CMM noma ozimele bomshini abakhulu, ukuqinisekisa ukuthi zonke izindiza ziyisikwele komunye nomunye nangaphansi.

Njengombusi oqondile, lezi zikwele kumele zifinyelele isitifiketi seBanga 00, okudinga ukuthi ama-engeli ahambisane nawo ngaphakathi kwemizuzwana emi-arc. Lo msebenzi uncike ekuzinzeni okuphezulu kwezinto ze-granite kanye nekhono elingenakuphikwa labachwepheshe abangochwepheshe abasebenzisa iminyaka eminingi yesipiliyoni enkambisweni yokubopha ngesandla ukuze bafinyelele i-geometry yokugcina engenaphutha ebusweni.

I-Ecosystem Yobuciko: Okungaphezu Kwetshe Nje

Igunya lala mathuluzi okumeta i-granite alikho nje kuphela ezintweni ezibonakalayo, kodwa kulo lonke uhlelo lwe-ecosystem olusekela isitifiketi sawo kanye nokukhiqizwa kwawo. Izinkampani eziholayo kulo mkhakha ziyaqonda ukuthi ukunemba kuyisiko, hhayi nje incazelo yomkhiqizo.

Kuqala ngabachwepheshe abangochwepheshe. Emashabhu okusebenzela akhethekile nalawulwa kakhulu, ochwepheshe bokugaya ngokunembile bavame ukuba neminyaka engamashumi amathathu noma ngaphezulu yesipiliyoni. Laba bantu banekhono ekusebenziseni amapuleti okubopha akhethekile kanye nama-compounds abrasive ukulungisa amaphutha amancane ngesandla, ngokuvamile besebenza ekubekezeleleni okubonwa ngezandla zabo kangcono kunezinzwa eziningi ze-elekthronikhi. Ulwazi lwabo oluqongelelwe lubavumela ukuthi bafinyelele ukuqeda okuphezulu okusunduza imingcele yokuthamba nokuqondile, ngezinye izikhathi kufinyelela esikalini se-nanometer ukuze kuqedwe kahle kakhulu okudingwa yizinhlelo zokusebenza zokuthwala umoya. Lokhu kuhlakanipha komuntu kuyisici esiyinhloko sokuhlukanisa ekufezeni izidingo zeBanga 00 eziqinile.

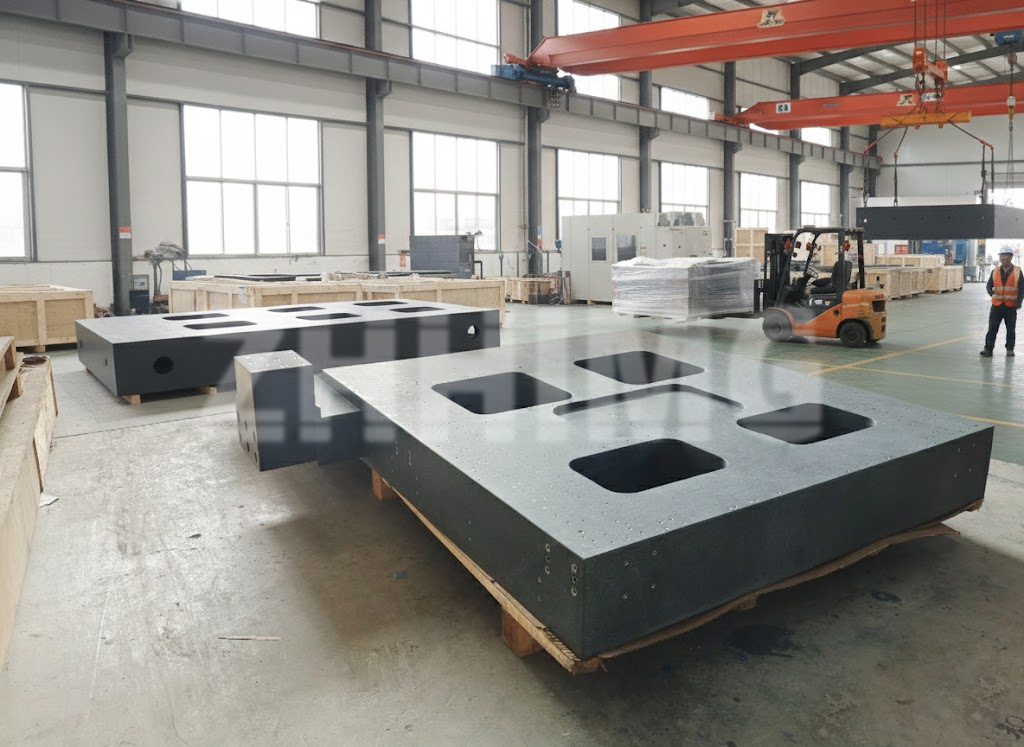

Lobu buciko buhlolwe ngokucophelela futhi buqinisekiswe. Indawo yokukhiqiza kumele ibe nozinzo olukhulu, inamakamelo ahlanzekile alawulwa yisimo sezulu, izisekelo zekhonkrithi ezilwa nokudlidliza, kanye nemishini yokulinganisa ekhethekile efana nama-laser interferometers kanye namazinga kagesi ahlolwa njalo futhi alandelelwa kuma-laboratory amazinga kazwelonke. Lokhu kuzibophezela kuqinisekisa ukuthi i-geometry eqinisekisiwe yengxenye ihlala iyiqiniso kusukela ngesikhathi iphuma efektri.

Ukuthembela kula mathuluzi asendulo kodwa aphelele kugcizelela iqiniso elijulile kubunjiniyela obunembile kakhulu: ukuphishekela isivinini esiguquguqukayo kanye nobunzima bokubala kumele kuhlale kuxhunywe eqinisweni lejiyomethri elingaguquki, eliqinisekisiwe. Irula eliqondile legranite elinokunemba kwebanga 00, isikwele segranite, kanye nesikwele segranite tri akuzona izinsalela zesikhathi esidlule; ziyizindinganiso ezidingekayo, ezingapheli eziqinisekisa ubuqotho bejiyomethri besikhathi esizayo. Ngokugcina ukunamathela okuqinile ezindinganisweni ze-DIN, JIS, ASME, kanye ne-GB, abakhiqizi abangochwepheshe baqinisekisa ukuthi ucezu lwetshe oluyisisekelo luhlala luyithuluzi eliyinkimbinkimbi kakhulu elitholakalayo lokuchaza iqiniso elinobukhulu.

Isikhathi sokuthunyelwe: Disemba-08-2025