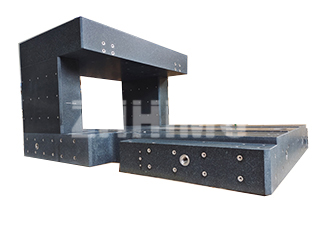

Uma kukhulunywa ngamapuleti obuso be-granite ngokwezifiso, abasebenzisi abaningi bayabuza ukuthi kungenzeka yini ukwengeza izimpawu zobuso eziqoshiwe—njengemigqa yokuxhumanisa, amagridi, noma izimpawu zokubhekisela. Impendulo inguyebo. Kwa-ZHHIMG®, asigcini nje ngokukhiqiza amapuleti obuso be-granite anembile, kodwa futhi sihlinzeka ngezixazululo zokudweba ngokwezifiso ukuthuthukisa ukusetshenziswa kahle kwezinhlelo zokusebenza ze-metrology kanye nokuhlanganiswa.

Kungani Kufanele Ufake Izimpawu Zomphezulu?

Izimpawu zobuso ezifana nemigqa yokuxhumanisa noma amaphethini egridi kwenza amapuleti obuso begranite abe nokuguquguquka okwengeziwe:

-

Ukubeka Nokuqondanisa - Imigqa yokuxhumanisa isiza onjiniyela ukuthi bavumelanise izinto zokusebenza kanye nezinsimbi ngokushesha.

-

Inkomba Yokulinganisa - Amagridi noma imigqa ewelayo isebenza njengeziqondiso ezibonakalayo zokuhlola ubukhulu.

-

Ukusekelwa Kokuhlanganiswa - Izimpawu zithuthukisa ukusebenza kahle kokuhlanganiswa noma ukulinganiswa kwemishini.

Lokhu kusebenza okwengeziwe kuguqula ipuleti lobuso le-granite lisuke endaweni yokubhekisela eyisicaba libe ithuluzi lokunemba elisebenziseka ngezindlela eziningi.

Ukunemba Kokuqopha

Ukukhathazeka okuvamile ukuthi ngabe ukuqopha kuzolimaza ukuthamba noma ukunemba kwepuleti lobuso be-granite. Kwa-ZHHIMG®, silandela iziqondiso eziqinile:

-

Ukuqopha kwenziwa kuphela ngemva kokuba ipuleti seligayiwe futhi lahlanganiswa lafinyelela endaweni efanelekile.

-

Izimpawu azijulile futhi zicutshungulwa ngokucophelela ukuze zingathinti ukunemba kwendawo yonke.

-

Ukunemba kokuqopha ngokuvamile kungafinyelela ku-±0.1mm, kuye ngobunzima bephethini kanye nezidingo zamakhasimende.

Lokhu kuqinisekisa ukuthi imiphumela yokubekezelela ukuthamba kanye nokulinganisa ihlala ingashintshi, kuyilapho umsebenzisi ezuza ezimpawu ezengeziwe zokucacisa.

Izinketho Zokwenza Ngokwezifiso

Amakhasimende angacela izinhlobo eziningi zophawu, okuhlanganisa:

-

Amagridi okuxhumanisa (imigqa ye-axis ye-XY)

-

Amaphuzu okubhekisela enkabeni

-

Izimpawu ze-Crosshair zokuqondanisa okubonakalayo

-

Izikali noma amarula enziwe ngokwezifiso aqoshwe ngqo epuletini

Izimpawu zingagcwaliswa ngombala ohlukile (njengomhlophe noma ophuzi) ukuze kubonakale kangcono ngaphandle kokuthinta ukunemba.

Ukusetshenziswa Kwamapuleti Okungaphezulu Kwe-Granite Aqoshiwe

Amapuleti obuso be-granite anezimpawu eziqoshiwe asetshenziswa kabanzi ku:

-

Amalabhorethri e-Metrology okulinganisa nokuhlola

-

Ukuhlanganiswa kwemishini ye-Optical ukuze kube nokubekwa okunembile

-

Ama-workshop okulungisa ngokunemba ukuze kulungiswe izingxenye

-

Izimboni ze-semiconductor kanye ne-electronics lapho kudingeka khona ukusethwa okunembe kakhulu

Ngokuhlanganisa ukubekezelelana okuphezulu kokuthamba namagridi okubhekisela okubonakalayo, abasebenzisi bathola ukusebenza kahle okukhulu nokunemba ekusebenzeni kwansuku zonke.

Kungani Ukhetha i-ZHHIMG®?

I-ZHHIMG® yaziwa emhlabeni wonke ngezixazululo ze-granite ezinembile ezenziwe ngokwezifiso. Ngobuchwepheshe beminyaka eminingi, izinhlelo zokuqopha ze-CNC ezithuthukisiwe, kanye nochwepheshe abanekhono, siyaqinisekisa:

-

Ubuso obuphansi obusezingeni le-nanometer ngaphambi kokuqopha

-

Ukuqopha ngokunemba kufika ku-± 0.1mm

-

Ukuhambisana nezindinganiso zamazwe ngamazwe (i-DIN, i-JIS, i-ASME, i-GB)

-

Izitifiketi zokulinganisa ezilandelelwa ezikhungweni zikazwelonke ze-metrology

Lokhu kwenza i-ZHHIMG® ibe ngumlingani othembekile wezimboni ezisezingeni lomhlaba, kusukela kubakhiqizi be-semiconductor kuya ezikhungweni zocwaningo.

Isiphetho

Yebo, kungenzeka ukucela imigqa eqoshwe nge-coordinate noma izimpawu zegridi kumapuleti obuso be-granite ngokwezifiso. Ngobuchwepheshe bokuqopha obuthuthukisiwe kanye nokulawulwa kwekhwalithi okuqinile, i-ZHHIMG® iqinisekisa ukuthi izimpawu zokunemba zithuthukisa ukusetshenziswa ngaphandle kokubeka engcupheni ukunemba. Kumakhasimende adinga kokubili ukuba yisicaba kanye nokusebenza, ipuleti lobuso be-granite elinezimpawu eziqoshiwe liyisisombululo esifanele.

Isikhathi sokuthunyelwe: Septhemba-26-2025