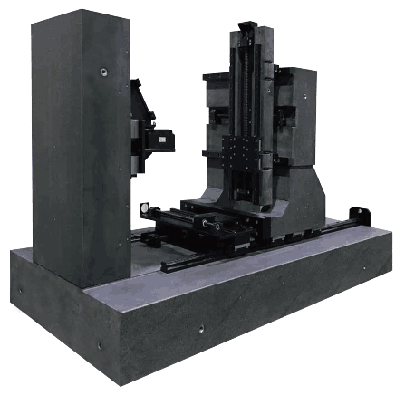

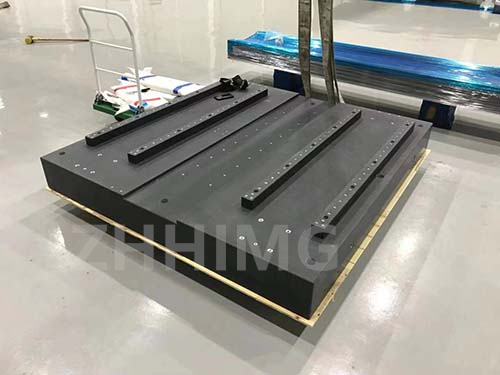

Ezimbonini zokukhiqiza ze-semiconductor kanye neze-display, imishini yokuhlola i-array idlala indima ebalulekile ekuqinisekiseni ikhwalithi yomkhiqizo. Ukusebenza kahle kwale mishini kungathuthukiswa kakhulu ngokukhetha izinto eziyisisekelo zomshini, futhi i-granite ivele njengoshintsho olukhulu kulokhu.

Ukuzinza Okungenakuqhathaniswa Kokusebenza Okuqhubekayo

Ukuhlolwa kwe-array kudinga ukunemba okuqondile, njengoba ngisho nokuphambuka okuncane kakhulu kungaholela ezicini ezingamanga noma kumaphutha angatholakali. Izisekelo zomshini we-granite, ezinobukhulu bazo obuphezulu obungaba ngu-3100 kg/m³, zinikeza ukuzinza okumangalisayo. Ngesikhathi senqubo yokuhlola, imishini ingase ibe ngaphansi kokudlidliza okuvela emishinini eseduze noma ezicini zemvelo. Isakhiwo esizinzile se-granite simelana ngempumelelo nalezi ziphazamiso zangaphandle, sigcina izinzwa zokuhlola nezingxenye ze-optical zihambisana kahle. Lokhu kuzinza kuqinisekisa ukuthi imishini ingaskena ama-array ngokuqhubekayo nangokunembile, kunciphisa isidingo sokuhlolwa kabusha nokuthuthukisa ukuphuma kwayo yonke into. Isibonelo, efektri yokubonisa iphaneli, ukwamukelwa kwezisekelo zomshini we-granite emishinini yokuhlola ama-array kwaholela ekwandeni okungu-20% kwamandla okuhlola nsuku zonke.

Ukunciphisa Ukudlidliza Okuphezulu Kokusebenza Okusheshayo

Ukudlidliza kungaphazamisa kakhulu ijubane lokuhlolwa kwe-array. Lapho imishini yokuhlola idlidliza, ijubane lokuskena livame ukuncishiswa ukuze kulondolozwe ukunemba, okunciphisa yonke inqubo. Izakhiwo zokudlidliza zemvelo ze-Granite - ukudambisa ziyinzuzo enkulu lapha. Isakhiwo sayo sangaphakathi esiyingqayizivele, esakhiwe yizinhlayiya zamaminerali ezixhumene, simunca futhi sichithe amandla okudlidliza ngempumelelo. Ngesisekelo somshini we-granite, imishini yokuhlola i-array ingasebenza ngesivinini esiphezulu sokuskena ngaphandle kokulahlekelwa ukunemba. Esikhungweni sokukhiqiza se-semiconductor, ngemuva kokufaka isisekelo sensimbi sokuqala nge-granite, ijubane lokuhlola lama-array wesekethe ahlanganisiwe landa ngo-30%, okwenza kube lula ukukhiqiza imijikelezo esheshayo.

Ukumelana Nokushisa Kwesikhathi Eside Sokusebenza

Ukushintshashintsha kwezinga lokushisa kuvamile ezindaweni zokukhiqiza, futhi kungathinta ukusebenza kwemishini yokuhlola ama-array. Ezinye izinto zingakhula noma zinciphe ngokushintsha kwezinga lokushisa, okubangela ukungalungi kahle kwezingxenye kanye nokuhlolwa okungalungile. I-Granite ine-coefficient yokwandisa ukushisa ephansi, okusho ukuthi igcina ukuma kwayo nobukhulu bayo ngisho nangaphansi kwamazinga okushisa ahlukahlukene. Lokhu kuzinza kokushisa kuvumela imishini yokuhlola ama-array ukuthi isebenze ngokuqhubekayo ngaphandle kwesidingo sokulungiswa okuvamile okubangelwa ukushisa. Ngenxa yalokho, imishini ingasebenza isikhathi eside, ikhulise ukusetshenziswa kwayo futhi ithuthukise ukusebenza kahle. Emugqeni wokukhiqiza ophezulu, ukusetshenziswa kwezisekelo zomshini we-granite kunciphisa isikhathi sokungasebenzi kwemishini ngenxa yezinkinga zokushisa ngo-40%.

Ukuqina Okuhlala Isikhathi Eside Kwemisebenzi Ebiza Kakhulu

Imishini yokuhlola i-array isetshenziswa njalo ezindaweni zezimboni, futhi isisekelo somshini sidinga ukumelana nobunzima bokusebenza kwansuku zonke. I-granite ihlala isikhathi eside, inokumelana okuhle kakhulu nokuguguleka kanye nokungangeni kwamakhemikhali. Ingamelana nokucindezeleka komshini, ukungqubuzana, kanye nokuvezwa kwamakhemikhali okungenzeka endaweni yokukhiqiza. Lokhu kuqina okuhlala isikhathi eside kunciphisa imvamisa yokufakwa esikhundleni kwesisekelo kanye nokugcinwa, kunciphisa izindleko zokusebenza zizonke. Ngaphezu kwalokho, isisekelo somshini we-granite esithembekile siqinisekisa ukusebenza okuzinzile kwesikhathi eside kwemishini yokuhlola i-array, okuqhubeka nokufaka isandla ekusebenzeni kahle okuthuthukisiwe.

Ekuphetheni, izisekelo zomshini we-granite zingathuthukisa kakhulu ukusebenza kahle kwemishini yokuhlola i-array. Ukuqina kwazo, amandla okudlidliza - ukucindezela, ukumelana nokushisa, kanye nokuqina kusebenza ndawonye ukuze kuvunyelwe ukuhlolwa okusheshayo, okunembe kakhulu, nokuthembekile. Kubakhiqizi abafuna ukwenza ngcono izinqubo zabo zokukhiqiza futhi bandise umkhiqizo wemisebenzi yabo yokuhlola i-array, ukutshala imali ezisekweni zomshini we-granite ezisezingeni eliphezulu, njengalezo ezinikezwe yi-ZHHIMG®, kuyisinqumo esihlakaniphile esingaletha izinzuzo ezinkulu.

Isikhathi sokuthunyelwe: Juni-10-2025