Ekukhiqizweni okunembile kwezingxenye zengilazi ze-elekthronikhi, i-optics, kanye nezakhiwo, ukufeza ukubekezelelana okuqinile kokubhoboza (ngokuvamile ngaphakathi kuka-±5μm noma okuqinile) kubalulekile.Izisekelo ze-granite eziqondile zivele njengesixazululo esishintsha umdlalo, zisebenzisa izakhiwo zazo ezibonakalayo ezihlukile ukuthuthukisa ukunemba kokubhoboza kanye nokuvumelana. Lesi sihloko sihlola indlela izisekelo ze-granite ezivumela ngayo ukulawula ukubekezelelana okuqinile emisebenzini yokubhoboza ingilazi.

Indima Ebalulekile Yokubekezelelana Ekubhobozeni Ingilazi

- Izingxenye zengilazi ezibonakalayokudinga ukubekezelelana kwemigodi ngaphakathi kuka-±2μm ukuze kugwenywe amaphutha okuxebuka kokukhanya

- Amaphaneli okubonisaudinga isikhala esifanayo sembobo ukuqinisekisa ukusebenza kwesikrini sokuthinta

- Amadivayisi ezokwelaphaizimbobo ezingenayo i-burr ezinokulawula okuqinile kobukhulu bezinhlelo zokusebenza ze-fluidic

Indlela Izisekelo Ze-Granite Ezithuthukisa Ngayo Ukunemba Kokubhoboza

1. Ukudambisa Ukudlidliza Okuphakeme Kokunemba Okuncane

Isakhiwo esiminyene se-granite (3,000–3,100 kg/m³) kanye nezinhlayiya zamaminerali ezixhumeneyo zisebenza njengesivikeli sokushaqeka semvelo:

- Izinga lokuncishiswa kokudlidliza>90% kumaza okubhoboza ajwayelekile (20–50Hz)

- Kunciphisa ukuxokozela kwamathuluzi, kuvimbela ukuqhekeka okuncane eduze kwemigodi yokubhoboza

- Ucwaningo lwesibonelo: Umkhiqizi wesibonisi osebenzisa izisekelo zegranite unciphise ukuhlukahluka kobubanzi bembobo kusukela ku-±8μm kuya ku-±3μm

2. Ukuzinza Kokushisa Kokubekezelelana Okungaguquguquki

Njengoba i-coefficient ephansi yokwanda kokushisa (4–8×10⁻⁶/°C), i-granite igcina ukuzinza kobukhulu:

- Kunciphisa ukuguquguquka kokushisa ngesikhathi sokubhoboza isikhathi eside

- Iqinisekisa ukunemba kwendawo yembobo ngisho nasezindaweni ezinokushintshashintsha kwezinga lokushisa okungu-±5°C

- Uma kuqhathaniswa nezisekelo zensimbi, i-granite inciphisa amaphutha abangelwa ukushisa ngo-60%

3. Ukuqina Okuphezulu Kokunemba Kwesikhathi Eside

Ukuqina kwe-Granite's Mohs okungu-6-7 kumelana nokuguguleka kangcono kunezisekelo zensimbi noma ezihlanganisiwe:

- Igcina indawo ithambile (± 0.5μm/m) ngaphezu kokusetshenziswa isikhathi eside

- Kunciphisa isidingo sokulungiswa kabusha komshini njalo

- Umkhiqizi we-semiconductor glass substrate ubike ukuthi amathuluzi agugile angaphansi ngo-70% uma esetshenziswa ezisekelweni ze-granite.

4. Isisekelo Esiqinile Sokunemba Kwendlela Yamathuluzi

Izindawo ze-granite ezigayiwe kahle (Ra≤0.1μm) zinikeza ipulatifomu efanele yokufaka:

- Ivumela ukuvumelanisa okunembile kwezimbazo zokubhoboza

- Kunciphisa amaphutha okuma okubangelwa ukuphambuka kwesisekelo

- Kuthuthukisa ukugoba kwembobo kube ngaphakathi kuka-0.01°

Ucwaningo Lwesibonelo: Izisekelo Zegranite Ekubhobozeni Ingilazi Ebonakalayo

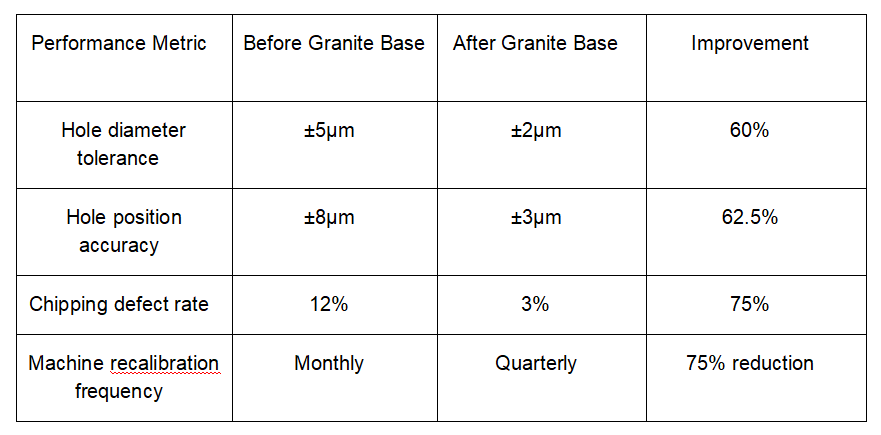

Umkhiqizi wezingxenye ze-optical ohamba phambili uthuthukiselwe ezisekelweni ze-granite ezisezingeni eliphezulu ze-ZHHIMG® zemishini yakhe yokubhoboza ingilazi ye-CNC:

Imiphumela ikhombisa ukuthi izisekelo ze-granite zivumela kanjani abakhiqizi ukuthi bahlangabezane nokubekezelelana okuqinile okudingekayo kwezingxenye ze-optical zezinga eliphezulu.

Izinto Ezibalulekile Eziqondiswe Ku-SEO

- Izisekelo ze-granite ezinembile kakhuluzibalulekile ekufinyeleleni ukubekezelelana okuqinile kwe-±5μm noma ukubhoboza ingilazi

- Ukudambisa ukudlidliza, ukuzinza kokushisa, kanye nezakhiwo zokumelana nokuguguleka zibhekana nezinselele ezibalulekile zokunemba

- Izifundo zamacala zibonisa intuthuko enkulu ekuqondeni kwemigodi kanye namazinga okuncipha kwamaphutha

- Ilungele izimboni ezidinga ukubekezelelana okuqinile kwezingxenye zengilazi: i-optics, i-electronics, amadivayisi ezokwelapha

Ngokuhlanganisa izisekelo ze-granite ezinembile kakhulu ekusethweni kokubhoboza ingilazi, abakhiqizi bangaphakamisa amakhono abo okunemba, bahlangabezane nezindinganiso zekhwalithi eziqinile, futhi bathole ithuba lokuncintisana ezimakethe ezinenani eliphezulu.

Isikhathi sokuthunyelwe: Juni-12-2025