Amapuleti obuso obunembile be-granite sekuyisikhathi eside ebhekwa njengenye yezisekelo ezithembeke kakhulu ku-metrology enobukhulu. Ahlinzeka ngendawo yokubhekisela ezinzile yokuhlola, ukulinganisa, kanye nokulinganisa okunembile kakhulu kuzo zonke izimboni ezifana nokukhiqizwa kwe-semiconductor, i-aerospace, i-CNC machining, kanye ne-metrology yokukhanya. Nakuba ukubaluleka kwawo kungangabazeki, kukhona ukukhathazeka okukodwa okuvame ukuvela ezinkundleni zobuchwepheshe kanye nemibuzo yamakhasimende:Umswakama uthinta kanjani amapuleti obuso be-granite?Ingabe umswakama ungabangela ukuthi i-granite yonakale noma ilahlekelwe ukunemba kwayo?

Impendulo, ngokocwaningo kanye namashumi eminyaka olwazi lwezimboni, iyaqinisekisa. I-Granite, ikakhulukazi i-granite emnyama enobukhulu obuphezulu, iyinto yemvelo ezinzile kakhulu enezakhiwo ezincane ze-hygroscopic. Ngokungafani namatshe anezimbobo njengemabula noma i-limestone, i-granite yakhiwa ngokucwiliswa kancane kwe-magma ngaphakathi koqweqwe loMhlaba. Le nqubo iphumela esakhiweni esiminyene esinezimbobo eziphansi kakhulu. Ngokwezibalo ezingokoqobo, lokhu kusho ukuthi i-granite ayimunci amanzi emoyeni, futhi ayivuvukali noma iguquguquke ezindaweni ezinomswakama.

Eqinisweni, lokhu kumelana nomswakama kungenye yezizathu ezibalulekile ezenza i-granite ithathe indawo yensimbi ephonswe ezisetshenziswa eziningi ze-metrology. Lapho insimbi ephonswe ingase igqwale noma ibole lapho ivezwa kumswakama ophezulu, i-granite ihlala izinzile ngamakhemikhali. Ngisho nasezindaweni zokusebenzela ezinamazinga omswakama angaphezu kuka-90%, amapuleti e-granite anembile agcina ukuzinza kwawo kobukhulu kanye nokuba yisicaba. Ukuhlolwa okwenziwa ezindaweni ezilawulwayo kuqinisekisa ukuthi ukuba yisicaba kwepuleti lobuso be-granite kuhlala ngaphakathi kokubekezelelana kwe-micrometer kungakhathaliseki ukuthi kunezinguquko kumswakama womoya.

Nokho, nakuba i-granite ngokwayo ingathinteki umswakama, indawo yonke yokulinganisa isabalulekile. Ukuminyana kungenzeka ezindaweni zokusebenzela ezingalawulwa kahle lapho amazinga okushisa ehla ngokuzumayo, futhi nakuba i-granite ingagqwali, amanzi ahlanganisiwe angashiya uthuli noma izinto ezingcolisayo eziphazamisa ukulinganisa. Izinsimbi ezibekwa ku-granite, njenge-dial gauges, amazinga kagesi, noma imishini yokulinganisa ehambisanayo, zivame ukuzwela kakhulu ezimweni zemvelo kunesisekelo se-granite uqobo. Ngenxa yalesi sizathu, ama-laboratories nama-workshop akhuthazwa ukuthi agcine amazinga okushisa nomswakama azinzile hhayi kuphela ku-granite kodwa nakumathuluzi ancike kuyo.

Ukumelana nomswakama okuphezulu kwe-granite kubaluleke kakhulu ezimbonini lapho izimo zemvelo kunzima ukuzilawula. Izakhiwo ze-semiconductor, izikhungo zezindiza, kanye nama-laboratory ocwaningo zivame ukusebenza ngezindinganiso eziqinile zemvelo, kodwa ukuzinza kwe-granite kuqinisekisa ungqimba olwengeziwe lokuvikeleka. Ezindaweni ezinezimo zezulu ezinomswakama ngokwemvelo, kusukela eNingizimu-mpumalanga ye-Asia kuya ogwini lwaseYurophu, amapuleti omhlaba we-granite ahlala ebonakala ethembekile kunezinye izindlela.

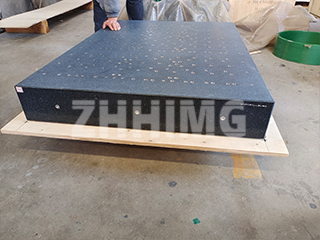

Kwa-ZHHIMG®, i-granite emnyama ekhethelwe imikhiqizo yokunemba inikeza izinga lokusebenza elikhulu nakakhulu. Njengoba inobuningi obungu-3100 kg ngemitha eyi-cubic kanye nesilinganiso sokumuncwa kwamanzi esingaphansi kuka-0.1%, inikeza ukuzinza okungenakuqhathaniswa. Lokhu kuqinisekisa ukuthi ukuthamba nokunemba kugcinwa isikhathi eside sokusetshenziswa. Amakhasimende akhiqiza ama-semiconductor, ama-optics, imishini ye-CNC, kanye nezikhungo ze-metrology zikazwelonke athembele kulezi zakhiwo lapho kudingeka ukunemba okuphelele.

Esinye isici okufanele sicatshangelwe ukugcinwa. Ngisho noma i-granite ingathinteki umswakama, imikhuba emihle kakhulu isiza ekwandiseni impilo yayo yokusebenza. Ukuhlanza njalo ngendwangu engena-lint kuvimbela ukunqwabelana kothuli. Izimbozo ezivikelayo zingagcina izindawo zingenazo izinhlayiya emoyeni lapho ipuleti lingasetshenziswa. Ukulinganiswa ngezikhathi ezithile ngamathuluzi aqinisekisiwe kuqinisekisa ukunemba kwesikhathi eside, futhi lokhu kubaluleke kakhulu ezindaweni ezinembe kakhulu lapho ukubekezelelana kungafinyelela ezingeni le-sub-micron. Kuzo zonke lezi zimo, ukumelana okungokwemvelo kwe-granite nomswakama kwenza umsebenzi ube lula futhi ubikezelwe kangcono kunezinsimbi noma ezinye izinto.

Umbuzo womswakama kanye namapuleti okucacisa i-granite uvame ukuvela ekukhathazekeni kwemvelo: kubunjiniyela bokucacisa, ngisho nethonya elincane kakhulu lemvelo lingaba nemiphumela elinganisekayo. Izinga lokushisa, isibonelo, liyisici esibalulekile ekuzinzeni kobukhulu. I-coefficient ephansi ye-granite yokwanda kokushisa kakade iyenza ibe ngenye yezinto ezinhle kakhulu zokulawula lokhu kuguquguquka. Nokho, uma kukhulunywa ngomswakama, onjiniyela bangaqiniseka ukuthi i-granite ingenye yezinketho ezinokwethenjelwa kakhulu ezitholakalayo.

Ezinkampanini namalabhorethri atshala imali eningi engqalasizinda ye-metrology, ukukhetha izinto ezibonakalayo akugcini nje ngokusebenza namuhla kodwa futhi kumayelana nokuzinza emashumini eminyaka ezayo. I-Granite izibonakalise ingumlingani wesikhathi eside kulo msebenzi. Ukumelana kwayo nomswakama kusho ukuthi ingafakwa futhi isetshenziswe ezindaweni ezahlukahlukene, kusukela emakamelweni okuhlanza kuya ezindaweni zezimboni ezisindayo, ngaphandle kokukhathazeka ngokuthi umswakama uzokwehlisa ukunemba kwayo.

Ekuphetheni, umswakama awubeki usongo ekuzinzeni noma ekuqondeni kwamapuleti ongaphezulu kwe-granite. Ngenxa yemvelo yayo eqinile, engeyona i-hygroscopic, i-granite ayikathintwa umswakama futhi iyaqhubeka nokuhlinzeka ngereferensi eqinile edingekayo ku-metrology yesimanje. Nakuba ukulawulwa kwemvelo kusabalulekile kumathuluzi kanye nokunemba okuphelele, i-granite ngokwayo ingathenjwa ukuthi imelane nezinguquko ezihlobene nomswakama. Yingakho, kuzo zonke izimboni nasemhlabeni jikelele, i-granite ihlala iyinto ekhethwayo yezisekelo zokulinganisa ngokunemba.

Kwa-ZHONGHUI Group (ZHHIMG®), lolu lwazi alugcini nje ngombono kodwa lufakazelwa nsuku zonke ngokubambisana nezinkampani ze-Fortune 500, amanyuvesi ahamba phambili, kanye nezikhungo ze-metrology zikazwelonke. Kwabonjiniyela abafuna ukuthembeka kwesikhathi eside, amapuleti obuso be-granite awameli nje kuphela isiko kodwa futhi nekusasa lokulinganisa okunembile kakhulu.

Isikhathi sokuthunyelwe: Septhemba-25-2025