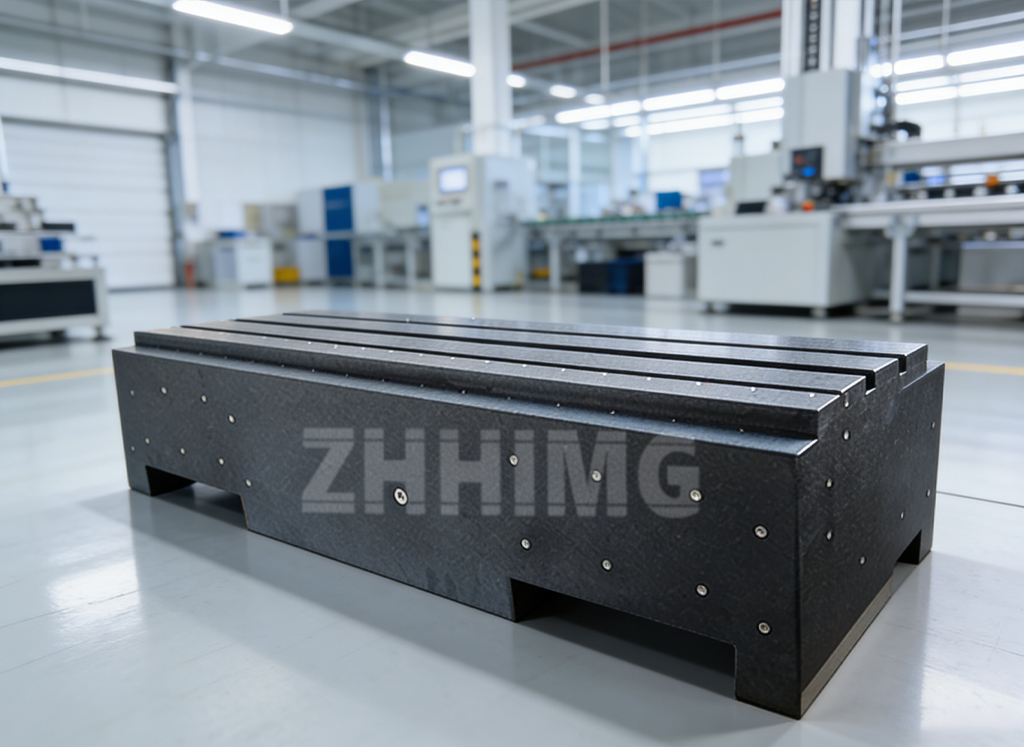

Amapulatifomu e-granite aqondile awasasetshenziswa kuphela njengezindawo zokubhekisela ezingasebenzi. Ekukhiqizeni kwanamuhla okunembe kakhulu, i-metrology, kanye nokuhlanganiswa kwemishini, avame ukusebenza njengezingxenye zesakhiwo ezisebenzayo. Lokhu kuthuthuka ngokwemvelo kuholela embuzweni ovamile futhi owusizo kakhulu ngesikhathi sezingxoxo zokuthengwa nokuklama: ingabe izimbobo zokufaka zingenziwa ngokwezifiso ku-ipulatifomu ye-granite enembile, futhi uma kunjalo, yiziphi izimiso okufanele zilawule ukwakheka kwazo ukuze kugwenywe ukuphazamisa ukunemba?

Impendulo emfushane inguyebo, izimbobo zokufaka zingenziwa ngokwezifiso, futhi ezicelweni eziningi ezithuthukisiwe, kumele zibe njalo. Amapulatifomu okunemba kwe-granite avame ukudingeka ukuze axhumane nama-air bearings, ama-linear motors, imigwaqo yokuqondisa, izinhlelo ze-optical, izinto ezifakiwe, noma ukuhlanganiswa okuphelele komshini. Amaphethini ajwayelekile emigodi awahlangabezani nalezi zidingo zokuhlanganiswa eziyinkimbinkimbi. Ukuhlelwa kwemigodi ngokwezifiso kuvumela ipulatifomu ye-granite ukuba yingxenye ebalulekile yesistimu kunokuba ibe yindawo yokubhekisela ehlukanisiwe.

Noma kunjalo, ukwenza ngokwezifiso akusho inkululeko engenamkhawulo. I-Granite iziphatha ngendlela ehlukile kakhulu kunensimbi, futhi ukwakheka kwemigodi okungalungile kungaletha ukucindezeleka kwangaphakathi, kunciphise ubuqotho besakhiwo, noma kuthinte kabi ukunemba kwesikhathi eside. Yingakho abakhiqizi abanolwazi bephatha ukwakheka kwemigodi njengomsebenzi wobunjiniyela kunesicelo esilula somshini.

Esinye sezici ezibaluleke kakhulu okufanele zicatshangelwe ukusatshalaliswa komthwalo. Yonke imbobo yokufaka iveza ukugcwala kokucindezeleka kwendawo ku-granite. Uma imbobo ibekwe eduze kakhulu, eduze kakhulu nemiphetho, noma ngaphansi kwezindawo ezinemithwalo ephezulu, insimu yokucindezeleka ingaphazamisa isakhiwo sangaphakathi se-granite. Ngisho noma ukuguquguquka kungabonakali ngokushesha, kungabonakala ngokuhamba kwesikhathi njengokuhamba okucashile okucashile. Ukuhlelwa kwembobo okuklanywe kahle kuqinisekisa ukuthi imithwalo evela emishinini efakiwe idluliselwa ngokulinganayo emzimbeni we-granite kunokuba igxilwe ezindaweni ezimbalwa.

Ubudlelwano phakathi kwezimbobo zokufaka kanye namaphuzu okusekela bubaluleke ngokulinganayo.Amapulatifomu e-granite aqondilengokuvamile zisekelwa ezindaweni ezithile ukuze kuncishiswe ukugoba kanye nokuphambuka kwamandla adonsela phansi. Uma izimbobo zokufaka zibekwe ngaphandle kokubheka la maphuzu okusekela, amandla okuqinisa noma imithwalo yokusebenza ingase iphikisane ne-geometry yokusekela ehlosiwe. Ezisetshenzisweni ezinembe kakhulu, lokhu kusebenzisana kungabangela izinguquko ezilinganiswayo ekusithekeni komphezulu. Ngenxa yalesi sizathu, ukwakheka kwesakhiwo sembobo kumele kuhlale kucabangela ukuthi ipulatifomu izosekelwa kanjani ngesikhathi sokulinganisa kanye nokusebenza.

Ukujula, ububanzi, kanye nendlela yokufaka intambo nakho kubaluleke kakhulu kunalokho abasebenzisi abaningi abakulindele. I-Granite ayibekezeleli ukufakwa kwentambo okunamandla noma ukujula ngokweqile ngendlela efanayo nezinsimbi. Izithako, ama-bushing, noma imikhono yensimbi eboshiwe zivame ukusetshenziselwa ukuhlinzeka ngezintambo eziqinile ngenkathi kuvikelwa itshe elizungezile. Ukukhetha uhlobo lokufaka kanye nendlela yokufaka akuthonyi nje amandla omshini kodwa futhi nokuzinza kwesikhathi eside. Izithako ezifakwe kabi zingaletha imifantu emincane noma ukucindezeleka okusele okonakalisa ukunemba ngokuhamba kwesikhathi.

Esinye isimiso esibalulekile ukulingana. Amaphethini emigodi angalingani angaholela ekusabalaleni kokucindezeleka okungalingani, ikakhulukazi lapho ipulatifomu ibhekene nezinguquko zokushisa noma imithwalo enamandla. Nakuba ukungalingani ngezinye izikhathi kungenakugwenywa ngenxa yokuklama imishini, onjiniyela abanolwazi bahlose ukulinganisela ukubekwa kwemigodi noma kuphi lapho kungenzeka khona. Ukulingana kusiza ukugcina ukuziphatha kokuguquguquka okubikezelwayo, okubalulekile ekulondolozeni ukuthamba kanye nokunemba kwejometri ngaphansi kwezimo zangempela.

Ukuziphatha kokushisa kumele kucatshangelwe nalapho kuklanywa imigodi yokufaka. I-Granite ine-coefficient ephansi yokwanda kokushisa, kodwa izinto zokufaka zensimbi nezingxenye ezifakiwe zinganda ngamazinga ahlukene. Ukuhlelwa kwemigodi okuvimbela izingxenye ngokuqinile kungadala ukucindezeleka kokushisa esibonakalayo se-granite-metal. Ukuvumela ukunyakaza okulawulwayo noma ukukhetha izinto zokufaka ezifanele kusiza ukuvimbela ukuqongelela kokucindezeleka kwesikhathi eside, ikakhulukazi ezindaweni ezinokushintshashintsha kokushisa.

Ngokombono wokukhiqiza, ukulandelana kwemisebenzi kubaluleke kakhulu njengokwakheka ngokwako. Ekukhiqizeni kwekhwalithi ephezulu, ukubhoboza nokufaka imigodi yokufaka kuhlanganiswa ngokucophelela nezinqubo zokugaya nokuhlanganisa. Ukwenza imishini enzima ngemva kokuqeda kokugcina kobuso kuyingozi yokuletha ukucindezeleka noma ukuphambuka kobuso. Yingakho ukwakheka kwemigodi okwenziwe ngokwezifiso kufanele kuchazwe ekuqaleni kwesigaba sokuklama, okuvumela umenzi ukuthi awahlanganise enkambisweni yokukhiqiza elawulwayo kunokuba awaphathe njengokucabanga kamuva.

Ukuhlolwa nokuqinisekiswa kudlala indima ebalulekile uma ukwenza ngokwezifiso sekuqediwe. Ipulatifomu yegranite enembile enezimbobo zokufaka kufanele ikalwe ekucushweni kwayo kokugcina, kufakwe izinto zokufaka kanye nezindawo eziqediwe ngokuphelele. Imibiko yokuhlola ukuthamba kanye ne-geometry kufanele ibonise isimo sangempela sokulethwa kunokuba ibe yisimo esiphakathi. Lokhu kunikeza ukuqiniseka kokuthi ukwenza ngokwezifiso akuzange kuphazamise indima yepulatifomu njengereferensi enembile.

Kubasebenzisi, ukuqonda lezi zimiso kusiza ekubekeni okulindelwe okungokoqobo. Izimbobo zokufaka ezenziwe ngokwezifiso aziyona ingozi uma zenziwe ngendlela efanele. Ngokuphambene nalokho, zivame ukuthuthukisa ukunemba kwesistimu ngokuqinisekisa ukuhambisana okufanele, ukufakwa okuphindaphindwayo, kanye nokudluliswa komthwalo okuzinzile. Izinkinga zivela kuphela lapho ukwakheka kwezimbobo kuqhutshwa kuphela ukulula noma izindleko, ngaphandle kokunaka ukuziphatha kwezinto ze-granite kanye nezidingo zokunemba.

Ezisetshenzisweni ezisebenzayo ezifana nezisekelo zemishini ye-semiconductor, izinhlelo zokunyakaza okunembile, amapulatifomu okuhlola okubonakalayo, kanye nezigaba zokuthwala umoya, amapulatifomu e-granite enziwe ngokwezifiso anezakhiwo zemigodi eziklanywe kahle aseyindinganiso. Abonisa ukuthii-granite enembileakuyona into ebuthakathaka okufanele igwenywe ekuhlanganisweni kwesakhiwo, kodwa iyisisekelo esinamandla kakhulu uma siphathwa ngesiyalo sobunjiniyela.

Ekugcineni, umbuzo awukhona ukuthi imigodi yokufaka ingenziwa ngokwezifiso yini epulatifomu ye-granite enembile, kodwa ukuthi iklanywe ngokuqonda okwanele kokunemba, ukuzinza, kanye nokusebenza kwesikhathi eside. Lapho izimiso zokubeka zihlonishwa futhi kwenziwa ngokwezifiso ngokunemba engqondweni, imigodi yokufaka iba yinzuzo esebenzayo kunokuba kube ukuvumelana. Kubunjiniyela obunembile kakhulu, ukwakheka okucatshangelwe kahle yikho okuvumela i-granite ukuthi isebenze hhayi nje njengendawo engaphezulu, kodwa njengereferensi yesakhiwo ethembekile eminyakeni ezayo.

Isikhathi sokuthunyelwe: Disemba 15-2025