Umzamo ongapheli wokwenza izinto zibe zincane kanye nokusebenza kahle kwezobuchwepheshe besimanje—kusukela kumaphaneli okubonisa athuthukile kuya kumathuluzi esayensi asezingeni eliphezulu—usuqede imingcele yezinto zobunjiniyela zendabuko. Ekufuneni ukunemba kwe-sub-micron ngisho nasezingeni le-nanometer, onjiniyela bahlala bephendukela ezintweni ezilungiselelwe iminyaka eyizinkulungwane ze-geological: i-granite yemvelo. Leli tshe elibonakala liphansi seliyisisekelo esingenakuxoxiswana ngaso semishini ebumba ikusasa lethu ledijithali.

Isidingo sokuqina nokunemba okungaguquki emikhakheni efana nokwenziwa kwe-semiconductor kanye ne-metrology ethuthukisiwe sigcizelela ukuthi kungani izingxenye ze-granite ezinembile zibaluleke kakhulu. Ngokungafani nezinsimbi, ezisengozini enkulu yokwanda kokushisa nokudlidliza, i-granite emnyama inikeza inhlanganisela eyingqayizivele yezakhiwo zomzimba ezidala indawo efanelekile yokusebenza okunembile kakhulu.

Isisekelo Sobuchwepheshe Bokubonisa Amaphaneli Ayisicaba

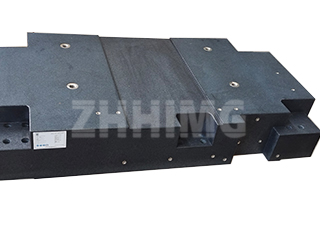

Ukwenziwa kwamaphaneli okubonisa esimanje—ikakhulukazi lawo asekelwe kubuchwepheshe be-Amorphous Silicon (a-Si) kanye ne-Low-Temperature Polycrystalline Silicon (LTPS)—kudinga imishini engagcina ukuthamba okumangalisayo kanye nokunemba kwendawo ezindaweni ezinkulu. Yilapho izingxenye ze-granite mechanical ze-a-Si Array kanye ne-precision granite yemishini ye-LTPS Array ziba zibaluleke kakhulu.

Lapho kukhiqizwa izisekelo zengilazi zendawo enkulu zokubonisa, ngisho nokuphambuka okuncane kakhulu esakhiweni somshini kungaholela ezinkingeni ezibizayo kanye nokulahlekelwa yisivuno. I-coefficient ephansi kakhulu ye-granite yokwanda kokushisa (cishe ingxenye yensimbi) iqinisekisa ukuthi isakhiwo somshini sihlala sizinzile ngisho nangesikhathi sokushintshashintsha kwezinga lokushisa endaweni ehlanzekile. Ngaphezu kwalokho, amandla ayo amahle kakhulu okudambisa ngaphakathi—aphakeme kakhulu kunensimbi ecijile noma insimbi—abalulekile ekuqedeni ukudlidliza okungabonakali. Lokhu kudlidliza, okungase kungabonakali ekuthinteni komuntu, kungaba yinhlekelele ezinqubweni ze-lithography, etching, noma zokubeka ezisetshenziswa ukwakha ama-transistors amancane namasekethe ku-array. Ngokuchitha la mandla ngokushesha, izisekelo ze-granite, imisebe, kanye nezingxenye ze-gantry kuqinisekisa ukuthi izigaba ezibucayi zihamba ngokunemba okuphindaphindekayo, okuphindaphindekayo okudingekayo ekukhiqizweni okuphezulu, okunezinga eliphezulu lokukhiqiza izibonisi ezinesinqumo esiphezulu.

Ukuqina okungokwemvelo kwe-granite kusho nokuthi izingxenye zomshini zingasekela imithwalo esindayo—njengezinhlelo ezinkulu ze-gantry, amakamelo okuhlanza, kanye namakhanda enqubo—ngokuphambuka okuncane, okuqinisekisa ukusebenza okuqhubekayo kuyo yonke imvilophu yokusebenza.

Ukunika amandla ukutholakala kwesayensi yangempela nge-Metrology

Ngaphandle kokukhiqiza, izici eziyingqayizivele ze-precision granite zibalulekile ocwaningweni lwesayensi oluyisisekelo kanye ne-metrology. Isibonelo esiyinhloko indima yayo kumathuluzi okuhlaziya anesinqumo esiphezulu, ikakhulukazi i-precision granite yemishini ye-XRD (i-X-ray Diffraction).

I-X-ray Diffraction iyindlela enamandla esetshenziswa ukunquma isakhiwo se-athomu kanye nesamangqamuzana sekristalu. Ukunemba okudingekayo kwi-goniometer—idivayisi ejikeleza isampula kanye ne-X-ray detector—kuyamangalisa. Noma yikuphi ukunyakaza noma ukudlidliza okuthinta i-engeli yokwenzeka noma yokuthola kungenza idatha eyinkimbinkimbi eqoqwe ingasebenzi ngokuphelele.

Ipulatifomu ye-metrology yesistimu ye-XRD ephezulu kumele ingabi nokukhukhuleka kokushisa futhi ikwazi ukusekela izinhlangano eziyinkimbinkimbi ze-optical neze-mechanical ngokuqina okumangalisayo. I-precision granite inikeza i-reference plane eyisicaba neyi-inert efanelekile edingekayo ukuze kufezwe izixazululo ze-angular ezidingekayo ekuhlaziyweni kwezinto ezithuthukisiwe. Izakhiwo zayo ezingezona ze-magnetic ziyinzuzo eyengeziwe, ukuqinisekisa ukuthi izinzwa ze-elekthronikhi ezizwelayo kanye nezinhlelo zokulawula i-electromagnetic ngaphakathi kwemishini azithintwa yi-magnetism eseleyo, inkinga evamile ngezinsimbi ze-ferrous.

Izinzuzo Ezingenakuqhathaniswa Zetshe Lemvelo Esikhathini Sokunemba

Impumelelo ye-granite kulezi zicelo ezidinga umzamo akuyona into eyenzeka ngengozi; ingumphumela oqondile wesayensi yayo yezinto ezibonakalayo:

-

Ukuzinza Okulinganayo: Ngemva kokuguga kwe-geological iminyaka eyizigidi, isakhiwo sangaphakathi se-granite emnyama esezingeni eliphezulu siyafana futhi sincishisiwe ekucindezelekeni, okuhlinzeka cishe ngokunyakaza kwangaphakathi okungenawo nhlobo ngokuhamba kwesikhathi, okuyinto ebalulekile ekugcineni ukulinganiswa.

-

Ukwanda Okuphansi Kokushisa: Ukusabela kwayo okuncane ekushintsheni kokushisa kugcina i-geometry, okuyisici esibalulekile kuzo zonke izinqubo zokunemba ezisebenza ezimweni ezilawulwayo, kodwa hhayi ezingezona ezishisayo ngokuphelele.

-

Ukudambisa Ukudlidliza: Ukwakheka kwamaminerali emvelo kunikeza ukudambisa okuvelele okungokwemvelo, okucindezela umsindo wemishini ngokushesha nangendlela ephumelela kakhulu kunezinsimbi ezakhiwe ngobunjiniyela.

-

Ayiboli futhi Ayinamagnethi: I-Granite ayigqwali futhi ayisebenzisi magnethi, yenza kube lula ukugcinwa kwayo futhi isuse izinkinga zokuphazamiseka kwe-electromagnetic ezingaphazamisa ukusetshenziswa kwezinsimbi ezibucayi.

Ngokusebenzisa lezi zakhiwo, abakhiqizi bangafinyelela ukubekezelelana kwezinga le-micron kanye ne-nanometer okudingekayo ukuze kuqhutshwe igagasi elilandelayo lokusungula izinto ezintsha kwezobuchwepheshe. Ukushintsha kusuka ezisekelweni zensimbi zendabuko kuya ezisekelweni ze-granite ezenziwe ngokwezifiso, ezisicaba kakhulu kumelela ushintsho oluyisisekelo kubunjiniyela obunembe kakhulu—ukuqashelwa ukuthi ukuze kube nokuzinza kwangempela, ngezinye izikhathi izinto ezindala kakhulu yizo ezingcono kakhulu. Kunoma iyiphi inkampani ezinikele ekufinyeleleni ukunemba okungenakuqhathaniswa kumishini ye-a-Si, i-LTPS, noma ye-metrology ethuthukisiwe, i-precision granite akuyona nje into yokukhetha izinto ezibonakalayo; kuyisidingo sokuncintisana.

Isikhathi sokuthunyelwe: Disemba-03-2025