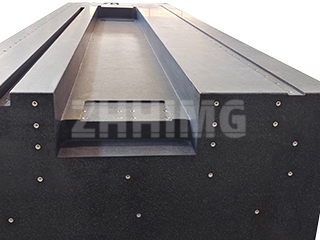

Uma uklama ipulatifomu yokucacisa i-granite, omunye wemibuzo evame ukubuzwa onjiniyela kanye nabakhiqizi bemishini ukuthi ngabe izimbobo zokufaka zingenziwa ngokwezifiso yini — nokuthi kufanele zihlelwe kanjani ukuqinisekisa ukusebenza kanye nokunemba.

Impendulo emfushane ithi yebo — izimbobo zokufaka epulatifomu yegranite zingenziwa ngokwezifiso ngokugcwele ngokwesakhiwo semishini kanye nezidingo zokufakwa kwemishini. Kodwa-ke, ukwakheka kumele kulandele izimiso ezithile zobunjiniyela kanye ne-metrology ukuze kulondolozwe ukuzinza nokunemba kwepulatifomu.

Amathuba Okwenza Ngokwezifiso

I-ZHHIMG® inikeza ukuguquguquka okuphelele kosayizi womgodi wokufaka, uhlobo, kanye nendawo. Izinketho zifaka:

-

Izithako ezifakwe intambo (insimbi engagqwali noma ithusi)

-

Ngezimbobo zamabholidi noma izikhonkwane ze-dowel

-

Izimbobo eziboshiwe zezikhonkwane ezifihliwe

-

Iziteshi zemigodi yomoya zezinhlelo ezithwala umoya noma i-vacuum clamping

Imbobo ngayinye iklanywa ngokunemba ezikhungweni zokucubungula i-CNC granite ngaphansi kwezimo zokushisa nomswakama ezingaguquki, okuqinisekisa ukunemba kokubekwa kwezinga le-micron kanye nokuhambisana kahle nomdwebo womklamo.

Izimiso Zokuklama Zokuhlelwa Kwemigodi

Ukuhlelwa kahle kwezimbobo zokufaka kubalulekile ukuze kulondolozwe kokubili amandla esakhiwo kanye nokuqina kobukhulu bepulatifomu ye-granite. Kunconywa izimiso ezilandelayo:

-

Gwema ukugxila ekucindezelekeni: Izimbobo akufanele zibe seduze kakhulu nemiphetho yesikhulumi noma eduze kwezicucu ezinkulu, okungenza buthaka ubuqotho besakhiwo.

-

Ukusatshalaliswa okulinganayo: Ukuhlelwa okulinganiselayo kunciphisa ukucindezeleka kwangaphakathi futhi kugcina ukwesekwa okufanayo.

-

Gcina ukubekezelelana kokusicaba: Ukuma kwembobo akumele kuthinte ukusicaba kwendawo yokubhekisela noma ukusebenza kokulinganisa.

-

Ukufanisa isikhombimsebenzisi semishini: Isikhala sembobo kanye nokujula kumele kuhambisane kahle nesisekelo semishini yekhasimende noma uhlelo lwesitimela sokuqondisa.

-

Cabanga ngokulungiswa kwesikhathi esizayo: Izindawo zemigodi kufanele zivumele ukuhlanza okulula nokufaka kabusha izinto ezifakiwe uma kudingeka.

Umklamo ngamunye uqinisekiswa ngokuhlaziywa kwezinto ezilinganiselwe (i-FEA) kanye nokulinganisa, okuqinisekisa ukuthi ipulatifomu yokugcina ifinyelela ukuqina nokunemba okuhle kakhulu.

Inzuzo Yokukhiqiza ye-ZHHIMG®

I-ZHHIMG® ingenye yabakhiqizi abambalwa bomhlaba wonke abakwazi ukukhiqiza izakhiwo ze-granite ezingafika kumamitha angu-20 ubude kanye namathani ayi-100 ngesisindo, ezinezimbobo zokufaka ezenziwe ngokwezifiso. Ithimba lethu lobunjiniyela lihlanganisa iminyaka eminingi yesipiliyoni se-metrology nobuchwepheshe besimanje bokucubungula ukuqinisekisa ukuthi yonke imininingwane ihlangabezana nezindinganiso ze-DIN, JIS, ASME, kanye ne-GB.

Zonke izinto ze-granite ezisetshenziswayo yi-ZHHIMG® Black Granite (ubuningi ≈3100 kg/m³), eyaziwa ngokuqina okumangalisayo, ukuzinza kokushisa, kanye nokunciphisa ukudlidliza. Ipulatifomu ngayinye ilinganiswa kusetshenziswa ama-interferometer e-laser e-Renishaw® kanye namazinga kagesi e-WYLER®, angalandelelwa ezikhungweni ze-metrology zikazwelonke.

Isikhathi sokuthunyelwe: Okthoba-16-2025