Ekufuneni isizukulwane esilandelayo sokukhiqizwa kwe-semiconductor kanye ne-sub-micron metrology, "isisekelo" kanye "nendlela" yizinto ezimbili ezibaluleke kakhulu. Njengoba abaklami bemishini belwela ukugeleza okuphezulu kanye nokuphindaphindwa kwezinga le-nanometer, ukukhetha phakathi kwe-umhlahlandlela wokuthwala umoya we-granitekanye nomhlahlandlela wendabuko wokuthwala ama-roller ube yisinqumo esibalulekile sobunjiniyela. Ngaphezu kwalokho, izinto ezisetshenziswa emshinini ngokwawo—ukuqhathanisa i-granite kanye ne-ceramics esebenza kahle kakhulu—zinquma imingcele yokushisa nokudlidliza yesistimu yonke.

Ukuqhathanisa Iziqondiso Zokuthwala Umoya Ze-Granite kanye Neziqondiso Zokuthwala Ama-Roller

Umehluko omkhulu phakathi kwalezi zinhlelo ezimbili usendleleni yazo yokusekela umthwalo kanye nokuphatha ukungqubuzana.

Iziqondiso Zokuthwala Umoya We-Granitezimelela ukuphakama kokunyakaza okungenakho ukungqubuzana. Ngokusebenzisa ifilimu elincane lomoya ocindezelwe—ngokuvamile eliphakathi kwama-micron angu-5 kuya kwangu-20—inqola ehambayo intanta ngokoqobo ngaphezu kwesitimela sokuqondisa se-granite.

-

Akukho Kungqubuzana Nokuguguleka:Ngenxa yokuthi akukho ukuthintana ngokomzimba, akukho "ukunamathela" (ukungqubuzana okungaguquki) okufanele kunqotshwe, futhi uhlelo alulokothi luguge. Lokhu kuvumela ukuskena okushelelayo nokusheshayo okuqhubekayo.

-

Iphutha Lokulinganisa:Enye yezinzuzo ezibaluleke kakhulu zama-air bearings yikhono lawo "lokulinganisa" ukungalingani kobuso obuncane be-granite rail, okuholela ekuhambeni okuqondile kune-rail uqobo.

-

Ukuhlanzeka:Ngaphandle kwesidingo sokugcotshwa, lezi ziqondiso zihambisana ngokwemvelo negumbi elihlanzekile, okwenza zibe yindinganiso yokuhlola i-wafer kanye nokukhiqizwa kwesibonisi sephaneli eyisicaba.

Iziqondiso Zokuthwala Ama-Roller, ngokuphambene nalokho, thembela ekuthinteni okungokoqobo kwama-roller noma amabhola ensimbi anembe kakhulu.

-

Umthamo Womthwalo Ophakeme:Ngezinhlelo zokusebenza ezifaka imithwalo esindayo noma amandla okusika aphezulu (njengokugaya ngokunemba), ama-roller bearings anikeza ukuqina okuphezulu kakhulu kanye nomthamo wokuthwala umthwalo.

-

Ukulula Kokusebenza:Ngokungafani nama-air bearings, adinga izinhlelo zokuhambisa umoya ezicindezelwe njalo nezihlanzekile kakhulu, ama-roller bearings “ayi-plug-and-play.”

-

Umklamo Oncane:Ama-bearings omshini avame ukusekela imithwalo ephezulu endaweni encane uma kuqhathaniswa nendawo enkulu edingekayo ukuze kube nephedi yokuthwala umoya ephumelelayo.

Nakuba ama-roller bearings eqinile futhi engabizi kakhulu ngokunemba okuvamile, ama-air bearings ayisinqumo esingaxoxiswana ngaso sezinhlelo zokusebenza lapho "ukuthintana" kuyisitha sokunemba.

Ukusetshenziswa Kweziqondiso Zokuthwala Umoya: Lapho Ukunemba Kuhlangana Nokugeleza Komoya

Ukwamukelwa kweziqondiso zokuthwala umoya kuye kwanda ngale kwelabhorethri kwaya ekukhiqizweni kwezimboni okunomthamo omkhulu.

Ku-Imboni Ye-semiconductor, ama-air bearings asetshenziswa ku-lithography kanye ne-wafer probing. Amandla okunyakaza ngesivinini esiphezulu ngaphandle kokudlidliza okuqinisekisa ukuthi inqubo yokuskena ayizifaki izinto ezisetshenziswayo kumjikelezo wesilinganiso se-nanometer.

In Ukuthwebula Izithombe Zedijithali kanye Nokuskena Okunefomethi Enkulu, ijubane elingaguquki lebhereyi yomoya libalulekile. Noma yikuphi "ukugoba" noma ukudlidliza okuvela kubhereyi yomshini kungaholela "ekuboshweni" noma ekuphambukeni esithombeni sokugcina esinesinqumo esiphezulu.

Imishini Yokulinganisa Ehlanganisiwe (i-CMM)thembela eziqondisweni zokuthwala umoya we-granite ukuqinisekisa ukuthi i-probe ingahamba ngokuthinta okulula kakhulu. Ukuntuleka kokungqubuzana kuvumela uhlelo lokulawula lomshini ukuthi luphendule ngokushesha ezinguqukweni ezincane kakhulu zobuso bengxenye elinganiswayo.

Isisekelo Sezinto Ezibonakalayo: I-Granite vs. I-Ceramic Yezisekelo Zomshini

Ukusebenza kwanoma yiluphi uhlelo lokuqondisa kunqunyelwe ukuzinza kwesisekelo esifakwe kuso. Sekungamashumi eminyaka, i-granite ibilokhu iyindinganiso embonini, kodwa izinto zobumba ezithuthukisiwe (njenge-Alumina noma i-Silicon Carbide) ziveza indawo ezinhlelweni zokusebenza ezisezingeni eliphezulu.

Izisekelo Zomshini WegraniteKuhlala kuyisinqumo esikhethwayo sama-90% ezinhlelo zokusebenza ezinembe kakhulu.

-

Izakhiwo Zokumanzisa:I-granite ingcono ngokwemvelo ekumunceni ukudlidliza okuvama kakhulu, okuyinto ebalulekile ku-metrology.

-

Ukuphumelela Kwezindleko:Ezisekelweni ezinkulu (kufika kumamitha amaningana), i-granite iyonga kakhulu ekutholeni nasekucubunguleni kunezitsha zobumba zobuchwepheshe.

-

I-Inertia Yokushisa:Ubukhulu be-granite busho ukuthi isabela kancane ekushintsheni kwezinga lokushisa elizungezile, okunikeza indawo ezinzile yokulinganisa isikhathi eside.

Izisekelo Zomshini We-Ceramic(ikakhulukazi i-Alumina) zisetshenziswa lapho kudingeka ukusebenza "okuphelele".

-

Isilinganiso Esiphezulu Sokuqina-kuya-Esisisindoni:I-ceramics iqine kakhulu kune-granite ngesisindo esifanayo. Lokhu kuvumela ukusheshisa okuphezulu kanye nokwehla kwejubane lezigaba ezihambayo ngaphandle kokuphazamisa isisekelo.

-

Ukuqina Okukhulu Kokushisa:Ezinye izinto zobumba zine-coefficient of thermal expansion (CTE) ephansi ngisho nangaphezu kwe-granite, futhi ukuhanjiswa kwazo okuphezulu kokushisa kuvumela isisekelo ukuthi sifinyelele ukulingana kokushisa ngokushesha.

-

Ubulukhuni:Izinto zobumba azikwazi ukuklwebheka futhi azikwazi ukuguguleka ngamakhemikhali, yize ziphuka kalula futhi zibiza kakhulu ukwenziwa ngezindlela ezinkulu.

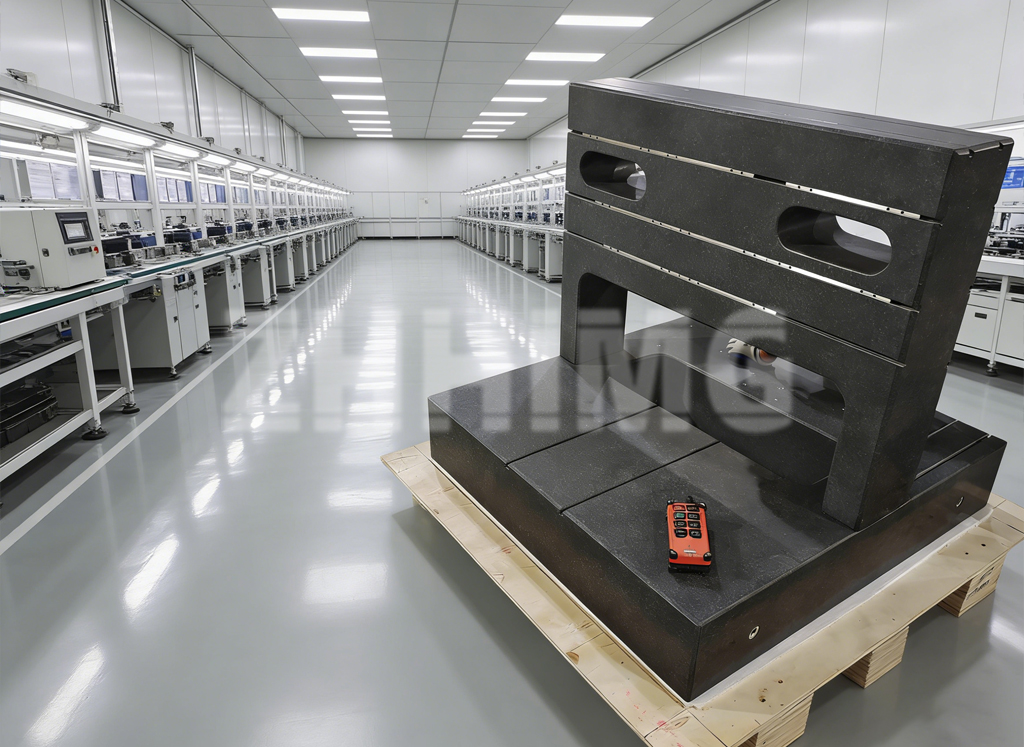

Ukuzibophezela kwe-ZHHIMG kwiSayensi Yezinto Ezibonakalayo

Kwa-ZHHIMG, sikholelwa ukuthi ikhambi elingcono kakhulu akuvamile ukuba yindlela eyodwa efanelana nazo zonke izinto. Ithimba lethu lobunjiniyela ligxile ekuhlanganisweni okuhlanganisiwe kwalezi zobuchwepheshe. Sivame ukusebenzisa isisindo sokudlidliza sesisekelo se-granite ukusekela ukunyakaza okungenakuphikiswana komhlahlandlela wokuthwala umoya, ngezinye izikhathi sifaka izinto zobumba ezindaweni ezibalulekile zokuguga okuphezulu noma ukuqina okuphezulu.

Njengomkhiqizi ohamba phambili, sinikeza imakethe yomhlaba wonke ukuqiniseka kwe-geological kwe-granite yezinga eliphezulu kanye nobuchwepheshe bezinhlelo zokunyakaza zesimanje. Indawo yethu yokukhiqiza ihlanganisa ubuchwepheshe bendabuko bokugoqa ngesandla—ikhono elidingekayo ukuze kufezwe ukuthambekela okudingekile kuma-air bearings—ne-CNC machining kanye ne-laser interferometry yesimanje.

Isiphetho: Ukwakha Impumelelo Yakho

Ukukhetha phakathi kwe-granite ne-ceramic, noma phakathi kwama-air kanye nama-mechanical bearings, ekugcineni kunquma imikhawulo yokusebenza kobuchwepheshe bakho. Konjiniyela emkhakheni we-aerospace, semiconductor, kanye ne-metrology, ukuqonda lokhu kuthengiselana kuyisihluthulelo sokuqamba izinto ezintsha. I-ZHHIMG Group iyaqhubeka nokucindezela imingcele yalokho okungenzeka ngokunyakaza okunembile, iqinisekisa ukuthi umshini wakho umi esisekelweni sokuqina okuphelele futhi uhamba ngokunemba okungenakuqhathaniswa.

Isikhathi sokuthunyelwe: Jan-22-2026