Ukuphishekela ukunemba okuphezulu kuyisisekelo sokukhiqiza kwesimanje okuthuthukisiwe. Emikhakheni esukela ekukhiqizweni kwe-semiconductor kanye ne-precision metrology kuya ekucutshungulweni kwe-laser kanye ne-CNC machining ephezulu, ukuzinza nokunemba kwesisekelo somshini kubaluleke kakhulu. Isisekelo esinamaphutha sihumusha ngqo emaphutheni ahlanganisiwe kumkhiqizo wokugcina.

Lo mhlahlandlela obalulekile unikeza abakhiqizi kanye nochwepheshe bokuthenga uhlaka oludingekayo ukuze bahambe emakethe eyinkimbinkimbi futhi bavikele i-Top Rated Custom Izisekelo Zomshini Wegranite, ukuqinisekisa ukusebenza kwesikhathi eside kanye nokuthembeka kwemishini yabo ebiza kakhulu.

Ukuqonda Indima Yesisekelo Somshini

Isisekelo somshini singaphezu nje kwesakhiwo esisekelayo esilula; yingxenye ebalulekile elawula i-geometry kanye nokusebenza okuguqukayo kwesistimu yonke. I-Granite iyinto ekhethwayo yokusetshenziswa okunembe kakhulu ngenxa yezici zayo ezivelele: i-coefficient yokwandisa ukushisa ephansi, amandla aphezulu okudambisa, kanye nokuzinza okungavamile kobukhulu. Lezi zakhiwo zinciphisa imiphumela yokushintshashintsha kwezinga lokushisa nomsindo wokudlidliza, okuyizimbangela ezimbili eziyinhloko zokunganembi kwemishini.

Izinkomba Zokusebenza Eziyinhloko Zezisekelo Ezisezingeni Eliphezulu

Lapho kuhlolwa isisekelo somshini we-granite owenziwe ngokwezifiso, abathengi kumele bagxile kuzilinganiso zobunjiniyela ezithile, ezingabalwa ezichaza ikhwalithi nokusebenza. Ukuhambisana nezindinganiso zamazwe ngamazwe, njengezindinganiso ze-DIN 876 noma ze-ISO, akunakuxoxiswana ngazo; ngemishini enembile kakhulu, izinga lokubekezelelana elingcono kune-Grade 00 livame ukudingeka, liqinisekiswe ngamathuluzi e-metrology anembile njenge-laser interferometers. Ikhwalithi ye-granite eluhlaza, ngokuvamile izinhlobo ezimnyama eziqinile, ibalulekile, njengoba ubuningi obuphezulu kanye nesakhiwo sezinhlamvu ezincane kuhlobene nokuzinza okungcono kobukhulu. Ngaphezu kwalokho, ikhono lesisekelo lokususa ukudlidliza komshini ngokushesha, okulinganiswa ngesilinganiso sokunciphisa okuphezulu, kubalulekile ekuvimbeleni ukusabalala kwamaphutha ekusikeni kwamandla noma ukunyakaza kwezimoto. Okokugcina, njengoba imishini eminingi ethuthukile idinga amajiyomethri ahlukile, ikhono lomhlinzeki lokuhlanganisa izingxenye ezifana nama-air bearings, ama-linear motors, kanye ne-guide rails ngqo ebusweni be-granite ngokunemba kwe-sub-micron kuyisici esichaza isisekelo esisezingeni eliphezulu.

Umehluko Phakathi Kwezisekelo Ezinhle NezingaPhansi

Umehluko omkhulu phakathi kwesisekelo somshini we-granite osezingeni eliphezulu, osezingeni eliphezulu kanye nophansi awukho nje ekupholiseni kokugcina, kodwa nasenqubweni yonke yokukhiqiza kanye nesisekelo sayo.

Isisekelo esingcono sisebenzisa ukugoqa okunembe kakhulu, okuvame ukuba yizigaba eziningi noma i-robotic, njengendlela yaso eyinhloko yokukhiqiza, ngokungafani nokugaya okulula kanye nokuklwebha ngesandla okusetshenziswa emikhiqizweni ephansi. Le nqubo ethuthukisiwe isekelwe yi-Quality Control eqinile, ehilela ukumepha kwe-laser interferometer kanye nokuqinisekiswa ngaphakathi kwezimo ezilawulwa amazinga okushisa aqinile, okunikeza abathengi imibiko yokulinganisa elandelekayo. Ngakolunye uhlangothi, izisekelo ezincane zithembele ekuhlolweni okuyisisekelo kwe-dial gauge kanye nokulawulwa okulinganiselwe kwemvelo. Ikhwalithi Yezinto Ezibalulekile ingenye into ebalulekile ehlukanisayo: izisekelo ezisezingeni eliphezulu zenziwe nge-granite emnyama eqinisekisiwe, egugile ngokwemvelo, enobukhulu obuphezulu, eqinisekisiwe ukuthi izonikeza ukuzinza okuqinisekisiwe kwesikhathi eside ngenxa yokukhululeka kokucindezeleka okufanele. Izisekelo eziphansi zisebenzisa i-granite yezinga eliphansi engase ihlupheke ngamaphutha angaphakathi, ukuguga okungafanele, futhi ngenxa yalokho ithambekele "ekungeneni" noma ekushintsheni kobukhulu ngokuhamba kwesikhathi. Okokugcina, ikhono lokuhlanganiswa ngokwezifiso libalulekile; umhlinzeki wekhwalithi ephezulu uqinisekisa ukuthi ukufakwa okunemishini enembile (njengezimbobo ze-T noma izimbobo ezinentambo) kuhlanganiswe ngaphandle kokubeka engcupheni ukuthamba okuphelele, kuyilapho ukufakwa okungafanele ezisekweni eziphansi kungabangela ukucindezeleka kwezinto zendawo noma ukungalingani.

Izindleko Ezifihliwe Zokuyekethisa Ngekhwalithi Eyisisekelo

Ukukhetha isisekelo se-granite esiphansi kuveza izingozi ezinkulu zesikhathi eside ezidlula kakhulu noma yikuphi ukonga kwezindleko kokuqala. Umthelela osheshayo nojulile kakhulu usekunciphiseni Ukunemba Kwemishini. Isisekelo esingenaso isicaba esidingekayo noma ukuzinza kobukhulu kunegalelo ngqo emaphutheni ahlelekile ku-geometry yomshini, okwenza kube nzima ukuhlangabezana nokubekezelelana okuqondiwe kwezingxenye zenani eliphezulu. Ngokuhamba kwesikhathi, amandla anganele okudambisa angaholela ekugugeni nasekudabukeni kwangaphambi kwesikhathi ezingxenyeni zomshini ezibizayo, kufaka phakathi iziqondiso eziqondile, ama-bearings, nama-spindles, okuholela ekwandeni kwezindleko zokulungisa kanye nesikhathi sokungasebenzi. Ngaphezu kwalokho, uma izinto ze-granite zingagugiswanga kahle ukuze kuncishiswe ukucindezeleka kwangaphakathi, isisekelo singase sibhekane ne-Geometric Creep, ushintsho oluhamba kancane kodwa olubucayi ngesimo esenza wonke umshini ungabi usizo emsebenzini wokunemba okukhulu, odinga ukulinganiswa okubizayo noma ukushintshwa okuphelele. Ekugcineni, isisekelo esingaphansi kwesilinganiso senza ikhwalithi yomkhiqizo ibe sengozini, sandisa amazinga okulahlwa, futhi sonakalise kakhulu idumela lomenzi ngokunemba.

Ukukhetha Umhlinzeki Ofanelekayo: Ukugxila Esikalini Nasebuchwephesheni

Kubalulekile ukuhlonza umhlinzeki onekhono lobuchwepheshe elidingekayo kanye namandla okukhiqiza. Funa izinkampani ezinerekhodi eliqinisekisiwe, ezisebenza ngaphansi kwezinhlelo zokuphatha ikhwalithi eziqinile, futhi ezingabhekana nezidingo zokwenza ngokwezifiso ngokweqile.

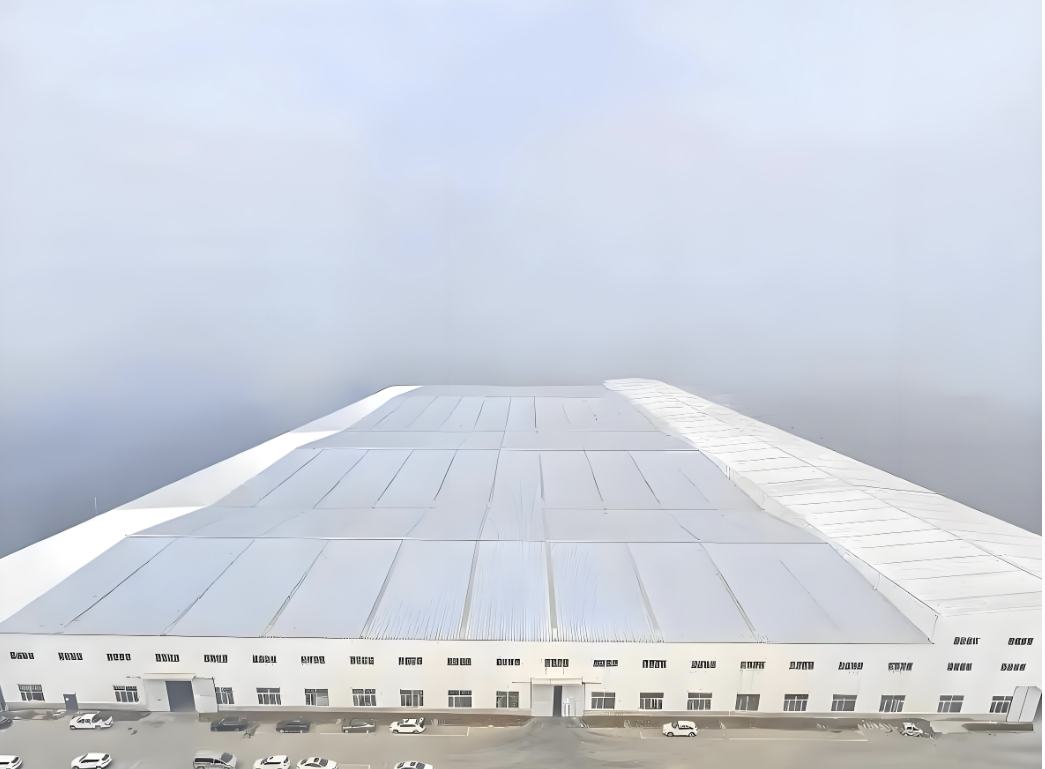

Isilinganiso sika-ZHHIMG ngokunemba okungeyona eyensimbi

Njengomholi oqashelwayo kulo mkhakha okhethekile,I-Zhonghui Intelligent Manufacturing (Jinan) Co., Ltd. (ZHHIMG®)ikhombisa amakhono adingekayo ukukhiqiza izisekelo zemishini ezisezingeni eliphezulu ngempela. Kusukela ngawo-1980, i-ZHHIMG ibilokhu igxile emishinini yokukhiqiza engeyona eyensimbi enembile kakhulu, ikakhulukazi izingxenye ezinkulu ze-granite.

Izindinganiso zabo zokusebenza zilandela ngokuqinile amazinga omhlaba wonke, okufakazelwa yizitifiketi ezihambisanayo ze-ISO 9001 (Ukuphathwa Kwekhwalithi), i-ISO 14001 (Ukuphathwa Kwemvelo), i-ISO 45001 (Impilo Nokuphepha Emsebenzini), kanye nophawu lwe-EU CE. Lesi sitifiketi esinezici eziningi siqinisekisa umkhiqizo owenziwe hhayi nje kuphela ngezincazelo zobuchwepheshe eziphezulu kodwa futhi nangomthwalo wemfanelo wemvelo kanye nokuphepha kwabasebenzi engqondweni.

Izinzuzo Zobuchwepheshe Nokukhiqiza

Izinzuzo eziyinhloko ze-ZHHIMG zibhekana ngqo nezidingo ezidinga kakhulu zezingxenye ze-granite ezenziwe ngokwezifiso: I-Extreme Scale Capability ibavumela ukuthi basebenze izingxenye ezinkulu kakhulu, bakhiqize izingcezu ze-granite ezenziwe ngokwezifiso ezingafika kumathani ayi-100 ngeyunithi eyodwa noma amamitha angama-20 ubude. Lo mthamo ubalulekile emishinini yesizukulwane esilandelayo, njengaleyo esetshenziswa ekukhiqizeni izibonisi zefomethi enkulu noma ekulingiseni izindiza. Ngaphezu kwalokho, umthamo wabo wokucubungula i-High-Volume, ofinyelela kumasethi ayi-10,000 ngenyanga, uqinisekisa isivinini kanye nokuvumelana kwama-oda amakhulu ngaphandle kokubeka engcupheni ukunemba okudingekayo kwezingxenye ngazinye. Ngaphandle kobukhulu obulula kanye nesimo, ubuchwepheshe be-ZHHIMG bufinyelela ku-Comprehensive Customization, obugxile ekuhlanganisweni okuyinkimbinkimbi kwezinto zemishini nezikagesi, okuhlanganisa ukucutshungulwa okunembile kwemigodi, izikhala, izinto ezifakiwe, kanye nemiklamo yokulinganisa ukukhanya kwesakhiwo emzimbeni we-granite, ukuqinisekisa ukushintshela okungenamthungo ekuhlanganisweni kokugcina kwethuluzi lomshini.

Isiphetho: Ukutshala imali ku-Precision

Isinqumo sokuthenga isisekelo somshini we-granite ngokwezifiso siwukutshalwa kwezimali kwesikhathi eside ekuqondeni, ekuzinzeni, kanye nekhono lokukhiqiza lesikhathi esizayo. Ngokugxila ezimisweni zobunjiniyela ezisunguliwe—ikakhulukazi, amazinga okubekezelelana okuqinile, ikhwalithi yezinto ezibonakalayo ephezulu, kanye nekhono lomhlinzeki eliqinisekisiwe lokwenza ngokwezifiso okukhulu nokuyinkimbinkimbi—abathengi bangakhetha ngokuqiniseka Izisekelo Zomshini We-Granite Olinganiselwe Kakhulu Ezizosebenza njengesisekelo esingaguquki sezinhlelo zabo zokusebenza ezibaluleke kakhulu.

Ukuze ufunde kabanzi mayelana nezingxenye ze-granite ezenziwe ngokwezifiso kanye nezixazululo zokukhiqiza ezinembile kakhulu, sicela uvakashele iwebhusayithi esemthethweni:https://www.zhhimg.com/

Isikhathi sokuthunyelwe: Disemba-29-2025