Uma ukhetha ipulatifomu yokucacisa yezicelo zezimboni, izinto ezikhethiwe zidlala indima ebalulekile ekunqumeni kokubili ukusebenza kanye nezindleko. Amapulatifomu okucacisa i-granite, amapulatifomu ensimbi ensimbi, kanye namapulatifomu e-ceramic ngalinye linezinzuzo nezithiyo ezihlukile, okwenza lifanelekele izinhlelo zokusebenza ezahlukene. Ngokombono wezindleko, umehluko wentengo phakathi kwalezi zinto ungathonya kakhulu izinqumo zokuthenga, ikakhulukazi ezimbonini lapho ukucacisa kuyinto eza kuqala khona.

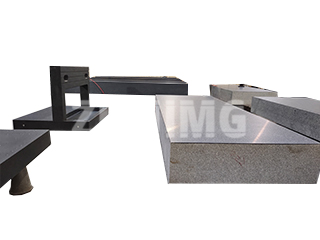

Amapulatifomu okunemba kwe-granite abhekwa kabanzi njengenye yezinketho ezizinzile nezithembekile kakhulu zokulinganisa nokulungisa ngokunemba okuphezulu. I-Granite, ikakhulukazi i-ZHHIMG® Black Granite, yaziwa ngezakhiwo zayo ezibonakalayo ezihlukile, okuhlanganisa ukuminyana kwayo okuphezulu, ukwanda kokushisa okuphansi, kanye nokumelana nokuguguleka nokuguquka. Inqubo yokukhiqiza amapulatifomu e-granite iyinkimbinkimbi futhi idinga imishini ethuthukisiwe ukuze kufezwe amazinga aphezulu okunemba okudingekayo. Le nqubo yokukhiqiza eyinkimbinkimbi, ehambisana nezakhiwo zezinto ezibonakalayo eziphakeme, yenza amapulatifomu e-granite abe yizinketho ezibiza kakhulu kwezintathu. Kodwa-ke, ukuqina kwawo kwesikhathi eside, izidingo zokunakekelwa okuncane, kanye nokunemba okungenakuqhathaniswa kuwenza abe ukukhetha okuthandwayo ezimbonini ezifana nezindiza, ukukhiqizwa kwe-semiconductor, kanye nokulinganisa ngokunemba okuphezulu.

Amapulatifomu ensimbi ehlanganisiwe, ngenkathi enikeza ukuzinza okuhle nokuqina, ngokuvamile ashibhile kunepulatifomu ye-granite. Insimbi ehlanganisiwe kulula ukuyikhiqiza, futhi izinto ngokwazo zishibhile kune-granite noma i-ceramic. Ngenkathi insimbi ehlanganisiwe inikeza ukwesekwa okwanele kwezicelo eziningi zezimboni, ithambekele kakhulu ekukhuleni kokushisa futhi ingase ingagcini izinga elifanayo lokunemba ngokuhamba kwesikhathi njengamapulatifomu e-granite. Ngakho-ke, amapulatifomu ensimbi ehlanganisiwe avame ukusetshenziswa ezimweni lapho izindleko ziyinkinga eyinhloko, futhi izidingo zokunemba aziqinile kangako. Ezinhlelweni zokusebenza lapho kukhona khona imikhawulo yesabelomali, amapulatifomu ensimbi ehlanganisiwe ayindlela ephumelelayo nengabizi kakhulu, enikeza ibhalansi enhle yokusebenza kanye nentengo.

Amapulatifomu e-ceramic, enziwe ngezinto ezifana ne-alumina (Al₂O₃), i-silicon carbide (SiC), noma i-silicon nitride (Si₃N₄), angenye indlela enikeza ukuzinza nokunemba okuhle kakhulu. Ama-ceramic aziwa ngokuqina kwawo okuphezulu, ukumelana nokuguguleka, kanye nokukhula okuphansi kokushisa, okwenza abe afaneleke kakhulu ezindaweni ezinembe kakhulu. Kodwa-ke, inqubo yokukhiqiza amapulatifomu e-ceramic ikhethekile kakhulu, futhi izinto ngokwazo zivame ukubiza kakhulu kune-cast iron. Ngenkathi amapulatifomu e-ceramic ngokuvamile enikeza iphuzu lentengo phakathi kwe-granite ne-cast iron, abhekwa njengangabizi kakhulu kune-granite kwizicelo eziningi ezinembe, ikakhulukazi ezimbonini ezifana nokukhiqiza i-semiconductor, izinhlelo zokulinganisa ze-optical, kanye ne-electronics yobuchwepheshe obuphezulu.

Ngokombono wezindleko, izinga livame ukulandela lo myalelo: Amapulatifomu e-Cast Iron abiza kancane, alandelwe amapulatifomu e-Ceramic, kanti amapulatifomu e-Granite Precision yiwo abiza kakhulu. Ukukhetha phakathi kwalezi zinto kuncike ezidingweni ezithile zohlelo lokusebenza, njengezinga lokunemba elidingekayo, izici zemvelo, kanye nesabelomali esitholakalayo.

Ezimbonini ezifuna amazinga aphezulu okunemba, ukutshala imali kumapulatifomu e-granite noma e-ceramic kunganikeza izinzuzo zesikhathi eside maqondana nokusebenza kahle nokuqina. Kodwa-ke, ezinhlotsheni zokusebenza lapho ukusebenza kahle kwezindleko kubaluleke kakhulu futhi izidingo zokunemba zingadingi kakhulu, amapulatifomu ensimbi ensimbi ahlinzeka ngesisombululo esisebenzayo ngaphandle kokubeka engcupheni ukusebenza kakhulu.

Isikhathi sokuthunyelwe: Okthoba-23-2025