Ezweni le-metrology enembile kakhulu, ithuluzi lokulinganisa i-granite—njengepuleti elingaphezulu, i-straightedge, noma i-master square—liyireferensi ephelele ye-planar. Lawa mathuluzi, aqedwe ngobuchwepheshe ngomshini futhi anikezelwe ukugoqa ngesandla, athola ukuqina kwawo nokunemba kwawo ngenxa yetshe eliqinile, elidala ngokwemvelo elakhiwe ngalo. Kodwa-ke, isikhathi sokuphila kanye nokunemba okugcinwe kwala mathuluzi abalulekile akuqinisekisiwe; kungumphumela wezindawo ezilawulwayo kanye nemikhuba yokusebenza ngokucophelela.

Kwa-ZHONGHUI Group (ZHHIMG®), siyaqaphela ukuthi nakuba i-granite yethu enobukhulu obuphezulu inikeza isisekelo esiyingqayizivele, izici eziningana eziseceleni komsebenzisi zithonya ngqo ukuthi ithuluzi lokunemba ligcina isikhathi esingakanani ukunemba kwalo okuqinisekisiwe. Ukuqonda lezi zici kubalulekile ekuvikeleni utshalomali lwakho.

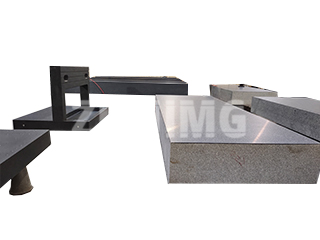

Izinsongo Eziyinhloko Zokuphila Isikhathi Eside Kwe-Granite

Ukuwohloka kwepulatifomu yokulinganisa i-granite kuvame ukubangelwa ukucindezeleka kwemishini kanye nemvelo kunokuba kube ukwehluleka kwezinto ezibonakalayo.

- Ukusatshalaliswa Komthwalo Okungafanele: Ingcindezi enkulu noma engalingani, ikakhulukazi uma igxile endaweni eyodwa yesikhulumi, ingaholela ekugugeni kwendawo noma ngisho nasekuguquguqukeni okuncane kwesikhathi eside. Lokhu kuvame ukubonakala lapho izinto zokusebenza ezisindayo zibekwa ngokuphindaphindiwe endaweni efanayo, okubangela ukuba indawo yokusebenza yengxenye ilahlekelwe ukuthamba kwayo okufanele.

- Ukungcola Kwemvelo: I-chip eyodwa, ukushefa insimbi, noma uthuli oluqothulayo lungasebenza njengephepha lesihlabathi phakathi kwe-granite kanye ne-workpiece. Indawo yokusebenza engcolile ayigcini nje ngokufaka amaphutha okulinganisa ngokushesha kodwa isheshisa kakhulu ukuguguleka kwendawo ye-granite, inciphise ngqo impilo yayo yenkonzo enembile.

- Izinto Zokusebenza Nekhwalithi Yomphezulu: Ukwakheka kanye nokuphela kwezinto ezilinganiswayo kudlala indima ebalulekile emazingeni okuguguleka. Izinto ezithambile njengethusi ne-aluminium zibangela ukuguguleka okuncane, kuyilapho izinto eziqinile, ikakhulukazi insimbi ecijile, zingenza i-granite iguge kakhulu. Ngaphezu kwalokho, izinto zokusebenza ezinobulukhuni obuphansi (ukuphela okuqinile) zithambekele ekuklwebheni ipulatifomu ye-granite egobile kahle, zilimaze unomphela indiza yokubhekisela.

- Ukusetshenziswa Kabi Kokusebenza Nokuthintana Okubi: Ubulukhuni obuphansi bomphezulu we-granite, yize buzuzisa ngezakhiwo zayo ezingezona ezikagesi futhi ezingaboli, buyenza iguge kalula ngenxa yokungqubuzana. Amasu anjengokuhamba ngokweqile kwento yokusebenza noma ithuluzi lokubhekisela phezu komphezulu—kunokuba iphakamise futhi ibeke—ethula ukungqubuzana okonakalisa ngokushesha ungqimba oluphezulu lwe-granite. Lokhu kuqinisekisa umthetho: amathuluzi okulinganisa i-granite ayizinto zokusebenza, hhayi amabhentshi okusebenza.

Ukukhiqiza Ngokucophelela: Isibopho Semishini Esizayo

Ukudalwa kwethuluzi lokulinganisa i-granite elisezingeni eliphezulu nelinembile kuncike kakhulu ekunembeni kwemishini yokucubungula esekelayo njengoba kwenza etsheni ngokwalo.

Ukuqinisekisa ukunemba kobukhulu bomkhiqizo wokugcina, yonke ingxenye yemishini yokucubungula amatshe kumele igcinwe ngokwezindinganiso ze-metrology. Lokhu kudinga ukuhlolwa okuphindaphindiwe kobukhulu bokuhlanganiswa komshini kanye nokunamathela ngokuqinile emikhubeni yobuchwepheshe yokuhlanza. Ngaphambi kokuba noma yikuphi ukucubungula amatshe okusemthethweni kuqale, imishini kumele ihlolwe ukuze kuqinisekiswe ukusebenza okuvamile. Ukusebenza komshini okungalungile akugcini nje ngokonakalisa kodwa kungaholela ekulahlekelweni kwezinto eziyigugu ze-granite ezikhethiwe.

Ukugcina izingxenye zangaphakathi zomshini—kusukela ebhokisini le-spindle kuya emishinini yokuphakamisa—kubaluleke kakhulu. Ukugcoba kumele kusetshenziswe ngokunembile kuzo zonke izindawo zokuhlanganisa, kufaka phakathi ama-bearings kanye nama-screw assemblies e-lead, ngaphambi kwanoma yikuphi ukusebenza. Ukuxhuma kumele kungabi namabala noma ama-burrs, futhi noma yikuphi ukugqwala kwangaphakathi noma ukungcola kumele kuhlanzwe ngokucophelela futhi kuphathwe ngezingubo zokulwa nokugqwala ukuze kuvinjelwe izinto zangaphandle ukuthi zingabeki engcupheni inqubo yokugaya.

Indima Ebalulekile Yekhwalithi Yokuhlanganiswa Kwemishini

Ikhwalithi yemishini esetshenziselwa ukucubungula i-granite ihlobene ngqo nokuzinza komkhiqizo wokugcina we-granite. Lokhu kudinga ukunakwa okujulile emininingwaneni yokuhlanganiswa kwemishini:

- Ubuqotho Bokubethela Nokuvala: Ama-bearings kumele ahlanzwe kahle ukuze kususwe izinto ezilwa nokugqwala futhi kuhlolwe ukuthi ajikeleziswa kahle yini ngaphambi kokuhlanganiswa. Amandla asetshenziswa ngesikhathi sokufakwa kwama-bearings kumele alingane, alingane, futhi afanele, kugwenywe ukucindezeleka emigwaqweni yomjaho futhi kuqinisekiswe ukuthi ubuso bokugcina buqondile ku-shaft. Ama-seal kumele acindezelwe ngokuhambisana nemigqa yawo ukuze kuvinjelwe ukusonteka, okuzofaka ukudlala nokungazinzi emshinini wokucubungula.

- Ukuqondaniswa Kwezinhlelo Zokunyakaza: Ezingxenyeni ezifana nezinhlelo zama-pulley, ama-axes kumele ahambisane kahle futhi aqondaniswe ukuze kuvinjelwe ukucindezeleka okungalingani, ukushelela kwebhande, kanye nokuguguleka okusheshayo—konke okuholela ekudlidlizeni okuphazamisa ukugoqana okunembile kwe-granite. Ngokufanayo, ukuthamba kanye nokuxhumana kwangempela kwezindawo zokuhlangana ekuxhumeni komshini kumele kuqinisekiswe futhi kulungiswe uma kutholwa noma yikuphi ukuguquguquka noma ama-burrs.

Ngamafuphi, ithuluzi lokulinganisa i-granite liyindinganiso yokubhekisela eqinile kodwa ehlelwe kahle. Isikhathi sayo sokuphila esiyingqayizivele siwumkhiqizo we-granite emnyama ye-ZHHIMG® esezingeni eliphezulu, ehlanganiswe nokulawula okuqinile kokuhlanzeka kokusebenza, ukuphathwa kahle kwezingxenye zomsebenzi, kanye nokugcinwa ngokucophelela kwemishini enembile eyiletha ekunembeni kwayo kokugcina, okuqinisekisiwe.

Isikhathi sokuthunyelwe: Okthoba-30-2025