Emikhakheni yezimboni esezingeni eliphezulu njengokukhiqiza ngokunemba kanye nokucubungula ama-semiconductor, ukuzinza kwemishini yokukhiqiza kunquma ngqo ikhwalithi yemikhiqizo kanye nokusebenza kahle kokukhiqiza. Kodwa-ke, izisekelo zensimbi ezivamile zivame ukuba nezinkinga zokuguquguquka kokushisa lapho zisebenza isikhathi eside noma lapho izinga lokushisa lemvelo lishintsha, okuholela ekwandeni kwezindleko kanye nokwehla kokwethenjwa kwamakhasimende. Ngokusho kwedatha yocwaningo lomkhakha, izinga lokukhubazeka kwemikhiqizo okubangelwa ukuguqulwa kokushisa kwezisekelo zensimbi ezihlanganisiwe lingafinyelela ngisho nangaphezu kuka-30% kwezinye izinqubo zokukhiqiza ezithinta izinga lokushisa, okukhawulela kakhulu intuthuko yamabhizinisi.

Imbangela eyinhloko yenkinga yokuguquguquka kokushisa kwezisekelo zensimbi ephonswe itholakala ezimpahleni zazo zezinto ezibonakalayo. I-coefficient yokwanda kokushisa kwensimbi ephonswe iphakeme kakhulu. Lapho imishini isebenza isikhathi eside futhi ikhiqiza ukushisa, noma lapho izinga lokushisa elizungezile lishintshashintsha, isisekelo sensimbi ephonswe sizobhekana nezinguquko ezingalawuleki zobukhulu. Ukuguquguquka okuncane okunjalo, ezimweni zokucubungula ngokunemba, kwanele ukuholela ochungechungeni lwemiphumela emibi njengokuphambuka kokunemba kokucubungula, ukuphazamiseka kwephethini yokuqopha, kanye namaphutha okuhlanganisa izingxenye, ekugcineni okuholela enanini elikhulu lemikhiqizo ekubeni yizinsalela ngenxa yokwehluleka ukuhlangabezana namazinga ekhwalithi.

Ukuphendula leli phuzu elibuhlungu embonini, kwavela ipulatifomu yokugoba i-granite ye-ZHHIMG, yanikeza amabhizinisi isisombululo sokuqina kokushisa esiphumelelayo. Ipulatifomu yokugoba i-granite ye-ZHHIMG yenziwe nge-granite yemvelo, enenzuzo eyingqayizivele ekuzinzeni kokushisa. I-coefficient yokwanda kokushisa kwe-granite iphansi kakhulu, ingu-1/5 kuya ku-1/10 kuphela yensimbi ephonswe. Ingagcina izinga eliphezulu lokuqina kobukhulu endaweni enezinguquko ezinkulu zokushisa, igweme ngempumelelo amaphutha okucubungula abangelwa ukuguqulwa kokushisa. Kungakhathaliseki ukuthi yindawo yokukhiqiza yokushisa okuphezulu noma indawo yokusebenza enomehluko omkhulu wokushisa phakathi kwemini nobusuku, ipulatifomu yokugoba i-granite ye-ZHHIMG ingaqinisekisa ukusebenza okunembile kwemishini futhi ithuthukise ngokuyisisekelo isivuno somkhiqizo.

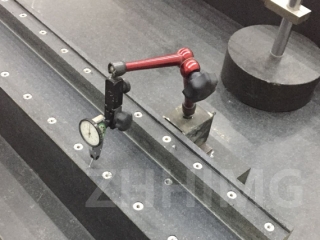

Ngaphezu kokuqina kwayo okuvelele kokushisa, ipulatifomu yokuqopha i-granite ye-ZHHIMG nayo inezinzuzo eziningi. Inobulukhuni obuphezulu kanye nokumelana okuqinile kokuguguleka, ingamelana nemithwalo yokucubungula enamandla aphezulu, futhi impilo yayo yesevisi inde kakhulu kuneyezisekelo zensimbi ephonswe. Izinto zemvelo ze-granite zinokusebenza okuhle kakhulu kokumunca ukushaqeka, okungamunca ngempumelelo ukudlidliza okukhiqizwa ngesikhathi sokusebenza kwemishini futhi kuqinisekise ukunemba kokucubungula. Okwamanje, ubuso bepulatifomu budlule ekuphathweni okunembile kokugaya, okunobucaba obungafinyelela ezingeni le-micrometer, okuhlinzeka ngesisekelo esiqinile nesithembekile sokucubungula ngokunembile.

Amacala amaningi okusetshenziswa okusebenzayo amabhizinisi aqinisekise ngokugcwele ukusebenza okuvelele kwepulatifomu yokusika i-granite ye-ZHHIMG. Ngemva kokwethula ipulatifomu yokusika i-granite ye-ZHHIMG, izinga lokukhubazeka kwebhizinisi elithile lokukhiqiza i-semiconductor lehle kakhulu lisuka ku-25% wokuqala laya ngaphakathi ku-5%, ukusebenza kahle kokukhiqiza kwanda ngo-30%, izindleko zokukhiqiza zehliswe kakhulu, futhi ukuncintisana kwemakethe kwathuthukiswa ngokuphawulekayo.

Uma ibhizinisi lakho likhathazwa yinkinga yokukhiqiza ebangelwa ukuguquguquka kokushisa kwezisekelo zensimbi ephonswe, ipulatifomu yokuqopha i-granite ye-ZHHIMG ngokungangabazeki iyisinqumo sakho esifanele. Ngokusebenza kwayo okuzinzile nokuthembekile, izokusiza ukuthi udlule ezinkingeni zokukhiqiza futhi ufinyelele ukuthuthuka okubili kwekhwalithi yomkhiqizo kanye nokusebenza kahle kokukhiqiza.

Isikhathi sokuthunyelwe: Meyi-14-2025