Enqubweni yokukhiqiza amabhethri e-lithium-ion, inqubo yokumboza, njengesixhumanisi esiyinhloko, ithinta ngqo ukusebenza nokuphepha kwamabhethri. Ukuqina kwepulatifomu yokulawula ukunyakaza komshini wokumboza ibhethri le-lithium kudlala indima ebalulekile ekunembileni kokumboza. I-Granite ne-cast iron, njengezinto ezisetshenziswa kakhulu zepulatifomu, umehluko ekuzinzeni kwazo kobukhulu udonsele ukunaka okukhulu. Lesi sihloko sizohlaziya ngokujulile ukuthuthuka okuphawulekayo ekuzinzeni kobukhulu be-granite uma kuqhathaniswa ne-cast iron epulatifomu yokulawula ukunyakaza kwemishini yokumboza ibhethri le-lithium ngokusebenzisa izakhiwo zezinto ezibonakalayo, idatha yokuhlola kanye namacala okusebenza asebenzayo.

Izakhiwo zezinto ezibonakalayo zinquma isisekelo sokuqina

Insimbi ephothiwe, njengezinto zendabuko zezimboni, yayisetshenziswa kabanzi emkhakheni wamapulatifomu okulawula ukunyakaza ngenxa yokusebenza kwayo okuhle kakhulu kokuphothiwe kanye nezinzuzo zezindleko. Kodwa-ke, izinto zensimbi ephothiwe zineziphambeko ezingokwemvelo. Isakhiwo sayo sangaphakathi siqukethe inani elikhulu le-graphite ephothiwe, elilingana nemifantu yangaphakathi futhi lizonciphisa ukuqina kwezinto. Okwamanje, i-coefficient yokwanda kokushisa kwensimbi ephothiwe iphakeme kakhulu, cishe ngo-10-12 ×10⁻⁶/℃. Ngaphansi kokuqongelela kokushisa okubangelwa ukusebenza kwesikhathi eside kokumbozwa kwebhethri le-lithium, ithambekele ekuguqukeni kokushisa. Ngaphezu kwalokho, kukhona ukucindezeleka kokuphothiwe ngaphakathi kwensimbi ephothiwe. Ngokuhamba kwesikhathi, ukukhululwa kokucindezeleka kuzobangela izinguquko ezingenakuguqulwa ngobukhulu bepulatifomu, okuthinta ukunemba kokumbozwa.

I-granite iyinto yemvelo eyakhiwe ngezinqubo ze-geological eminyakeni engamakhulu ezigidi. Isakhiwo sayo sangaphakathi sekristalu siminyene futhi siyafana, futhi sinokuzinza okuphezulu okungokwemvelo. I-coefficient yokwandisa okuqondile kwe-granite ingu-0.5-8×10⁻⁶/℃ kuphela, okuyi-1/2-1/3 yaleyo yensimbi ephonswe, futhi ayizweli kakhulu ezinguqukweni zokushisa. Okwamanje, i-granite iqinile ekubunjweni, inamandla okucindezela afinyelela ku-1,050-14,000 kilograms ngesentimitha lesikwele. Ingamelana ngempumelelo nemiphumela yamandla angaphandle kanye nokudlidliza, inikeze isisekelo esiqinile nesizinzile sepulatifomu yokulawula ukunyakaza. Cishe akukho ukucindezeleka okusele ngaphakathi kwayo, futhi ngeke kubangele izinguquko zobukhulu ngenxa yokukhululwa kokucindezeleka, okuqinisekisa ukuzinza kobukhulu bepulatifomu kusukela engqikithini yezinto.

Idatha yokuhlola iqinisekisa umehluko wokusebenza

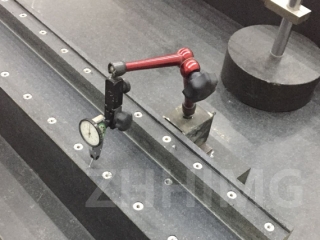

Ukuze kuqhathaniswe ngokubonakalayo umehluko ekuzinzeni kobukhulu phakathi kwe-granite ne-cast iron, ithimba locwaningo lenze ukuhlolwa okukhethekile. Kwakhethwa amapulatifomu amabili okulawula ukunyakaza komshini wokumboza ibhethri le-lithium onencazelo efanayo, enziwe nge-granite ne-cast iron ngokulandelana, futhi ahlolwa ngaphansi kwezimo ezifanayo zemvelo. Ukuhlolwa kwalingisa isimo sangempela sokusebenza komshini wokumboza ibhethri le-lithium. Ngokusebenzisa imishini ngokuqhubekayo, izinguquko zosayizi wepulatifomu ngezikhathi ezahlukene zaqashwa.

Imiphumela yokuhlola ikhombisa ukuthi ngemva kokusebenza okuqhubekayo amahora angama-24, ngenxa yokushisa okudalwe ukusebenza kwemishini, izinga lokushisa lobuso beplatifomu yezinto zensimbi ephonswe landa cishe ngo-15℃, okwaholela ekukhuleni okungu-0.03mm ebangeni lobude beplatifomu. Ngaphansi kwezimo ezifanayo, ukushintshashintsha kosayizi weplatifomu yegranite cishe akunakwa, futhi ububanzi bokuguquguquka kosayizi balo bungaphansi kuka-0.005mm. Ngemva kwamahora ayi-1000 okuhlolwa kokuguga kwesikhathi eside, ngenxa yokukhululwa kokucindezeleka kwangaphakathi kanye nokuqongelela kokuguquguquka kokushisa, iphutha lokuba yisicaba leplatifomu yensimbi ephonswe landa kusukela ku-0.01mm yokuqala kuya ku-0.05mm. Iphutha lokuba yisicaba leplatifomu yegranite lihlala ligcinwe ngaphakathi kuka-0.015mm, futhi inzuzo yokuzinza kobukhulu isobala.

Impumelelo emangalisayo ekusetshenzisweni okusebenzayo

Ekukhiqizweni kwangempela kwebhizinisi elikhulu lokukhiqiza amabhethri e-lithium, kwakusetshenziswa amapulatifomu okulawula ukunyakaza kwensimbi ephothiwe. Njengoba isikhathi sokusebenza kwemishini sanda, ukunemba kokugqoka kwehla kancane kancane, okwaholela ekuqineni kokugqoka okungalingani, ukungaguquguquki kahle kwamashidi e-electrode ebhethri, kanye nesilinganiso somkhiqizo esinamaphutha esifinyelela ku-8%. Ukuze kuxazululwe le nkinga, ibhizinisi lithathe indawo yamapulatifomu okulawula ukunyakaza kwemishini ethile ngezinto ze-granite.

Ngemva kokushintsha, ukuzinza kobukhulu bemishini kuthuthukiswe kakhulu. Ngesikhathi somjikelezo wokukhiqiza wezinyanga eziyisithupha, umshini wokumboza osebenzisa ipulatifomu yegranite uhlale ugcina iphutha lokujiya kwengubo ngaphakathi kuka-±2μm, futhi izinga lomkhiqizo onephutha lehliswe kakhulu laba ngaphansi kuka-3%. Okwamanje, njengoba amapulatifomu egranite engadingi ukulinganiswa nokugcinwa okunembile okuvamile njengamapulatifomu ensimbi ensimbi, asindisa amabhizinisi inani elikhulu lezindleko zokulungisa imishini kanye nesikhathi sokungasebenzi minyaka yonke, futhi andise ukusebenza kahle kokukhiqiza ngaphezu kuka-15%.

Ekuphetheni, ekusetshenzisweni kwepulatifomu yokulawula ukunyakaza kwemishini yokumboza ibhethri le-lithium, i-granite, enezakhiwo zayo ezivelele zezinto ezibonakalayo, isebenza kahle kakhulu kunensimbi ecijile ngokwezinga lokuqina. Kungakhathaliseki ukuthi ngokombono wemvelo yezinto ezibonakalayo, idatha yokuhlola, noma imiphumela yokusetshenziswa engokoqobo, i-granite inikeza isiqinisekiso esithembekile sokukhiqizwa okunembile nokuzinzile kwezinqubo zokumboza ibhethri le-lithium. Ngokuthuthuka okuqhubekayo kwezidingo zekhwalithi yomkhiqizo embonini yebhethri le-lithium, amapulatifomu okulawula ukunyakaza enziwe nge-granite nakanjani azoba ukukhetha okuyinhloko embonini.

Isikhathi sokuthunyelwe: Meyi-22-2025