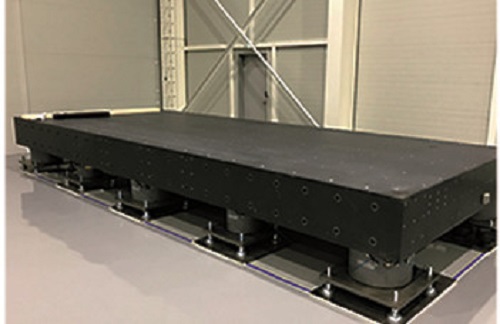

Embonini yamabhethri e-lithium, njengemishini yokukhiqiza eyinhloko, ukuzinza kwepulatifomu yokunyakaza yomshini wokumboza kudlala indima ebalulekile ekhwalithini yokukhiqiza yamabhethri e-lithium. Eminyakeni yamuva nje, amabhizinisi amaningi okukhiqiza amabhethri e-lithium athole ukuthi lapho ethuthukisa imishini yawo, ngemva kokushintsha isisekelo sensimbi esivamile ngesisekelo se-granite, ukuzinza kwepulatifomu ehambayo kufinyelele igxathu elifanele. Ngokusho kokuhlolwa kwangempela, izinga lokuthuthukisa ukuzinza lifinyelele ku-200%. Okulandelayo, sizohlola izizathu zalokhu.

Umehluko ezimpahleni zezinto ezibonakalayo ubeka isisekelo sokuqina

Ukuqina kokushisa: I-Granite inezinzuzo ezibalulekile

Ngesikhathi sokusebenza komshini wokumboza ibhethri le-lithium, izici ezifana nokusebenza kwemoto nokushisa okubangelwa ukungqubuzana kungabangela ukuguquguquka kwezinga lokushisa elizungeze imishini. I-coefficient yokwanda kokushisa kwensimbi ephonswe cishe ingu-12×10⁻⁶/℃, futhi usayizi wayo ushintsha kakhulu lapho izinga lokushisa lishintsha. Isibonelo, lapho izinga lokushisa likhuphuka ngo-10℃, isisekelo sensimbi ephonswe esingamamitha angu-1 singandiswa ngo-120μm. I-coefficient yokwanda kokushisa kwe-granite iphansi kakhulu, kuphela (4-8) ×10⁻⁶/℃. Ngaphansi kwezimo ezifanayo, ukunwetshwa kwesisekelo se-granite esingamamitha angu-1 ubude kungu-40-80μm kuphela. Ukuguquguquka okuncane kokushisa kusho ukuthi endaweni yokukhiqiza enezinguquko zokushisa ezivamile, isisekelo se-granite singagcina kangcono ukunemba kokuqala kwepulatifomu ehambayo futhi siqinisekise ukuzinza kwenqubo yokumboza.

Ukusebenza kokuqina nokunciphisa: I-Granite ingcono kakhulu

Ukuqina kunquma ikhono lento yokumelana nokuguquguquka, kuyilapho ukusebenza kokuncibilikisa kuhlobene nokusebenza kahle kokumunca amandla okudlidliza. Nakuba insimbi ephonswe inokuqina okuthile, inesakhiwo se-graphite esiqhekekile ngaphakathi. Ngaphansi kwesenzo sesikhathi eside sokushintshana kokucindezeleka okubangelwa ukusebenza kwemishini, ithambekele ekugxiliseni ukucindezeleka, okuholela ekuguqukeni futhi kuthinte ukuzinza kwepulatifomu. Ngokuphambene nalokho, i-granite iqinile ekubunjweni, inesakhiwo sangaphakathi esiminyene kanye nokuqina okuhle kakhulu. Isakhiwo sayo esiyingqayizivele samaminerali siyinika ukusebenza okuhle kakhulu kokuncibilikisa, okwenza ikwazi ukuguqula ngokushesha amandla okudlidliza abe amandla okushisa ukuze ahlakazeke. Izifundo zikhombisile ukuthi endaweni yokudlidliza engu-100Hz, i-granite inganciphisa ngempumelelo ukudlidliza ngaphakathi kwemizuzwana engu-0.12, kuyilapho i-cast iron idinga imizuzwana engu-0.9. Lapho umshini wokumboza ibhethri le-lithium usebenza ngesivinini esikhulu, isisekelo se-granite singanciphisa kakhulu ukuphazamiseka kokudlidliza ekhanda lokumboza, siqinisekise ukujiya kokugqoka okufanayo nokungaguquguquki.

Ukusekelwa kwedatha yobuningi ukuze kuthuthukiswe ukuzinza

Ukuhlolwa kokudlidliza: Umehluko we-amplitude uhlukile

Izikhungo zobungcweti zenze izivivinyo zokudlidliza ezisekelweni zokunyakaza zemishini yokumboza ibhethri le-lithium ehlonyiswe ngezisekelo zensimbi ecijile kanye nezisekelo ze-granite ngokulandelana. Lapho umshini wokumboza usebenza ngokujwayelekile futhi ijubane libekwe ku-100m/min, kusetshenziswa inzwa yokudlidliza enembile kakhulu ukukala ubukhulu bezingxenye ezibalulekile zepulatifomu. Imiphumela ikhombisa ukuthi ubukhulu bepulatifomu yokuhamba yesisekelo sensimbi ecijile bungu-20μm ohlangothini lwe-X-axis kanye no-18μm ohlangothini lwe-Y-axis. Ngemva kokufakwa esikhundleni sesisekelo se-granite, ubukhulu be-X-axis behle baba ngu-6μm kanti obe-Y-axis behle baba ngu-5μm. Kusukela kudatha ye-amplitude, kungabonakala ukuthi isisekelo se-granite sinciphise ubukhulu be-vibration yepulatifomu ehambayo eziqondisweni ezimbili eziyinhloko cishe ngo-70%, kunciphisa kakhulu umthelela wokudlidliza ekunembileni kwe-coating futhi kunikeze ubufakazi obuqinile bokuthuthukiswa kokuzinza.

Ukugcinwa kokunemba kwesikhathi eside: Ukukhula kancane kwamaphutha

Ngesikhathi sokuhlolwa kokusebenza kokumboza okuqhubekayo kwamahora angu-8, ukunemba kokubekwa kwepulatifomu kwaqashwa ngesikhathi sangempela. Uma kusetshenziswa isisekelo sensimbi ephonswe, iphutha lokubekwa kwepulatifomu landa kancane kancane ngokuhamba kwesikhathi. Ngemva kwamahora angu-8, iphutha lokubekwa elihlanganisiwe lama-axes e-XY lifinyelela ku-±30μm. Iphutha lokubekwa kwepulatifomu yokunyakaza enesisekelo se-granite ngemva kwamahora angu-8 liyi-±10μm kuphela. Lokhu kubonisa ukuthi ngesikhathi senqubo yokukhiqiza yesikhathi eside, isisekelo se-granite singalondoloza kangcono ukunemba kwepulatifomu, sigweme ngempumelelo ukuphambuka kwesikhundla sokumboza okubangelwa ukukhukhuleka kokunemba, futhi siqinisekise ngokwengeziwe inzuzo yaso yokuzinza.

Ukuzinza kokuqinisekiswa komphumela wokukhiqiza kwangempela kuthuthukisiwe

Emgqeni wangempela wokukhiqiza webhizinisi elithile lokukhiqiza amabhethri e-lithium, izisekelo zensimbi ezibunjiwe zeminye imishini yokumboza zathuthukiswa zaba izisekelo ze-granite. Ngaphambi kokuthuthukiswa, izinga lokukhubazeka komkhiqizo laliphezulu njengo-15%, kanti amaphutha amakhulu afaka phakathi ukujiya kokugqoka okungalingani kanye nokuphambuka kokugqoka emaphethelweni eshidi le-electrode. Ngemuva kokuthuthukiswa, izinga lokukhubazeka kwemikhiqizo lehle kakhulu laya ku-5%. Ngemva kokuhlaziywa, kungenxa yokuthi isisekelo se-granite sithuthukisa ukuzinza kwepulatifomu ehambayo ukuthi inqubo yokumboza iba nembe kakhulu futhi ilawuleke, kunciphisa ngempumelelo amaphutha omkhiqizo abangelwa amapulatifomu angazinzile. Lokhu kubonisa ngokugcwele umthelela omuhle wesisekelo se-granite ekhwalithini yokukhiqiza emishinini yokumboza ibhethri le-lithium.

Ekuphetheni, kungakhathaliseki ukuthi kuvela ekuhlaziyweni kwemibono yezakhiwo zezinto ezibonakalayo, idatha yangempela yokuhlola inani, noma impendulo yomphumela emgqeni wokukhiqiza, kubonisa ngokusobala ukuthi ukuthuthukiswa kokuzinza kwepulatifomu yokuhamba yomshini wokumboza ibhethri le-lithium kusetshenziswa isisekelo se-granite uma kuqhathaniswa nesisekelo sensimbi ephonswe kungafinyelela ku-200%. Kumabhizinisi akhiqiza amabhethri e-lithium aphishekela ikhwalithi ephezulu kanye nomthamo ophezulu, isisekelo se-granite ngokungangabazeki siyisinqumo esibalulekile sokuthuthukisa ukusebenza komshini wokumboza.

Isikhathi sokuthunyelwe: Meyi-19-2025