Enhliziyweni yezimboni zokukhiqiza imishini kanye ne-metrology kukhona ithuluzi eliyisisekelo: i-Cast Iron Surface Plate. Lezi zinsimbi zokubhekisela ezihleliwe zibalulekile ekuhlolweni okunembile kwezingxenye zokusebenza, ukubhala ngokunembile, kanye nokusebenza njengezilinganiso ezizinzile zokusethwa kwamathuluzi omshini. Kwa-ZHHIMG®, ukuzibophezela kwethu ekuqondeni okuphezulu kudlulela ngale kwemikhiqizo yethu edumile ye-granite kuya ezindinganisweni eziqinile ezilawula wonke amathuluzi abalulekile e-metrology. Ukuqonda inqubo ecophelelayo—kusukela ekubunjweni kuya ekufakweni—kubaluleke kakhulu ekuqinisekiseni ikhwalithi kanye nobude besikhathi sale mpahla ebalulekile yesitolo.

Ukuqeqeshwa Kwezinto Zokwakha: Izinyathelo Zokuqapha Ekubunjweni Kwensimbi Ecijile

Ukukhiqizwa kwamapuleti obuso bensimbi ecijile esezingeni eliphezulu kuqala ngokuziphatha okuqinile embonini yokusekela. Abasebenzi kumele banamathele ngokuqinile ekugelezeni kwenqubo okulawulwayo okuhloselwe ukuba lula nokufana. Lokhu kuhilela ukuklama amaphethini anciphisa inani lezindawo zokuhlukanisa kanye nezinsimbi zesihlabathi ngenkathi kuqinisekiswa ama-engeli afanele okudweba kanye nobukhulu bodonga obuguqukayo ngokushelela. Ukukhetha uhlelo lokubopha olufanele kubalulekile; kumele kuqinisekiswe ukuqina okulandelanayo, okuholela ekubunjweni okuhlelekile ngokulinganayo, okuncishiswe ukucindezeleka.

Okubaluleke kakhulu, ikhwalithi yesihlabathi sokubumba ithonya ngqo ukuthungwa kokugcina. Ingxube yesihlabathi kumele ibe nokuvuleka okuhle kakhulu, amandla amanzi, ukugeleza, i-plasticity, kanye nokugoqeka. Lokhu kufezwa ngokulandela ngokuqinile ukulandelana kokudla kwezinto—isihlabathi esidala, isihlabathi esisha, ubumba, impuphu yamalahle, namanzi—nokulawula isikhathi sokuxuba ngqo emizuzwini eyisithupha kuya kweyisikhombisa. Isihlabathi esixubile sibe sesiphunyuzwa futhi sihlungwe ukuze kuthuthukiswe ukuvuleka kwaso kanye nokugeleza kwaso ngaphambi kokusetshenziswa.

Inqubo yokuthela ngokwayo idinga ukugxila okungantengantengi. Insimbi encibilikisiwe kumele igonywe kahle futhi isuswe ngokuphelele ngaphambi kokuba kuqale ukuthela. Ukugeleza okuqhubekayo nokuzinzile kubalulekile ukuvimbela amaphutha njengokuguguleka kwesihlabathi kanye nokwakheka kwemigodi yesihlabathi. Ukusabela okusheshayo kunoma yikuphi ukuvuza kuyadingeka ukuze kugwenywe amaphutha amakhulu njengokuvala okubandayo kanye nokuthululwa okungaphelele. Okokugcina, inqubo yokuhlanza ngokucophelela iqinisekisa ukuthi ukuphola okupholile kususwa esikhumbeni ngaphandle kokulimala, okuveza indawo engenamaphutha okuqala.

Umklamo, Amaphutha, kanye Nobuningi: Ukuqinisekisa Ubuqotho Besakhiwo

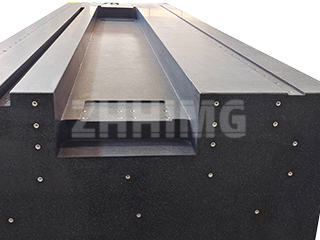

Ipulatifomu yensimbi ecijile esezingeni eliphezulu yenzelwe ukuhlala isikhathi eside. Ngokuvamile yakhelwe njengezakhiwo ezinezinhlangothi ezimbili noma uhlobo lwebhokisi, izindawo zazo zokusebenza zivame ukuba yisikwele noma unxande. Ukuqina kwesakhiwo kuncike kakhulu ezicini ezifana nezindonga eziseceleni kanye nezimbambo zokuqinisa, okumele zilinganiswe ngokunembile ngokusekelwe kumthamo odingekayo wokuthwala umthwalo kanye nebanga lokunemba. Ukuphakama kwalezi zimbambo zokuqinisa—kungakhathaliseki ukuthi zinohlangothi olulodwa, uhlanga olugcwele, noma uhlanga oluyisicaba—kunikeza ukucindezeleka nokusekelwa okudingekayo.

Ngisho noma kunezilawuli zokuphonsa eziqinile kakhulu, kungase kube namaphutha amancane. Kumapulatifomu angaphansi kokunemba kweBanga "0," amazinga embonini avumela ukulungiswa kokuvalwa kwemigodi emincane yesihlabathi (ububanzi obungaphansi kuka-14 mm) kusetshenziswa izinto ezifanayo, uma nje ubulukhuni bezinto zokulungisa buphansi kunensimbi ezungezile. Kodwa-ke, indawo yokusebenza kumele ekugcineni ingabi namaphutha amakhulu, okuhlanganisa imifantu, ama-porosity, ukufakwa kwe-slag, kanye nemigodi yokuncibilika, futhi indawo yokuphonsa kumele ibe bushelelezi ngopende onamathele ngokuqinile. Ukukhetha ipulatifomu eye yaguga ngokwemvelo noma ukwelashwa kokushisa okwenziwe kubaluleke kakhulu, njengoba lezi zinqubo zinciphisa ukucindezeleka kwangaphakathi futhi zivimbela ukuguquka kwe-diagonal esikhathini esizayo.

Ukufakwa Nokunakekelwa: Ukulondoloza Ukunemba

Ipulatifomu yensimbi ephonswe ngensimbi, kungakhathaliseki ukuthi ikhwalithi yayo injani, inembe njengokufakwa kwayo. Kumelwe ilinganiswe ngokuvundlile nomthwalo usatshalaliswe ngokulinganayo kuzo zonke izindawo zokusekela, ngokuvamile kufezwa kusetshenziswa izinyawo ezilungisekayo zebhulakhethi elisekelayo. Le nqubo yokulinganisa, eqondiswa ileveli ye-elekthronikhi enembile kakhulu noma ileveli yohlaka, ibalulekile ekufezeni ukunemba kwayo okulinganiselwe.

Ukuze kugcinwe ukunemba, indawo ezungezile ibalulekile. Izinga lokushisa lokusebenza kufanele ligcinwe cishe ku-20℃ (± 5℃), futhi ukudlidliza kumele kugwenywe ngokuqinile. Ngaphambi kokuba umsebenzi uqale, indawo kufanele ihlanzwe ngokucophelela ukuze kususwe isihlabathi esisele, ama-burrs, uwoyela, kanye nokugqwala, njengoba ngisho nezinto ezincane ezingcolisayo ziphazamisa ukunemba. Indawo esezingeni eliphansi, noma ebushelelezi, ibalulekile ukuze kuhlale isikhathi eside.

Ngokusetshenziswa okufanele kanye nokugcinwa ngokucophelela—ukugwema izindawo ezinomswakama, ezigqwalisayo, noma ezishisa kakhulu—ukunemba kwendawo yokusebenza yesikhulumi sensimbi engagqwali kungagcinwa iminyaka emibili noma ngaphezulu. Isakhiwo sesikhulumi ngokwaso singahlala amashumi eminyaka. Uma ukunemba kwehla, singabuyiselwa ngokuphelele ngokulungiswa kochwepheshe noma ukuphinda sibekwe kabusha (ukuklwebha). Ukuhlolwa njalo ngokumelene nendinganiso yaso yokulinganisa kuyimpoqo, njengoba ukusebenzisa ipuleti elingaphansi kwendinganiso kuzoholela ekuphambukeni kokulinganisa futhi kuthinte ikhwalithi yomkhiqizo wokugcina.

Njengethuluzi eliyisisekelo emkhakheni wezimoto, wezindiza, wezinsimbi, kanye nowemishini esindayo, ipulatifomu yensimbi ecijile iyisiqiniseko sokuthi ukunemba kwakhiwe kusukela phansi kuya phezulu.

Isikhathi sokuthunyelwe: Okthoba-31-2025