Emkhakheni wokukhiqiza i-PCB (Printed Circuit Board), ukunemba kokubhoboza kunquma ngqo ukusebenza kukagesi kanye nezinga lokukhiqiza lebhodi lesifunda. Kusukela kuma-chips efoni ephathekayo kuya kumabhodi esifunda sezindiza, ukunemba kwawo wonke umgodi wezinga le-micron kubalulekile empumelelweni noma ekwehlulekeni komkhiqizo. Izisekelo ze-granite, ngezakhiwo zazo ezihlukile zezinto ezibonakalayo kanye nezinzuzo zesakhiwo, ziba "umlingani wegolide" wemishini yokubhoboza i-PCB, okwenza ukunemba kwemboni kufinyelele ekuphakameni okusha.

I. Inzuzo Engokwemvelo: Ukusebenza okuzinzile kubeka isisekelo sokunemba

Ukuqina okuvelele kokushisa

Ngesikhathi senqubo yokubhoboza i-PCB, ukushisa okukhiqizwa ukujikeleza okusheshayo kwe-drill bit kungafinyelela ku-60-80℃. Ukwanda kwezinto zensimbi ezivamile ngenxa yokushisa kungabangela kalula ukuthi indawo yokubhoboza ishintshe. I-coefficient yokwanda kokushisa kwe-granite ingu-4-8×10⁻⁶/℃ kuphela, okuyi-1/5 kuphela yensimbi. Lokhu kusho ukuthi noma izinga lokushisa elizungezile lishintsha kakhulu, ukuguquka kwesisekelo se-granite kungashaywa indiva. Ngemva kokuba umenzi othile webhodi lesifunda amukele isisekelo se-granite, iphutha lendawo yokubhoboza lancishiswa kusuka ku-±50μm kuya ku-±10μm, okuthuthukisa kakhulu ukuhambisana kokusebenza kukagesi kwebhodi lesifunda.

2. Ukusebenza okunamandla kakhulu kokuzamazama komhlaba

Ukudlidliza okuvama kakhulu komshini wokubhoboza ngezinkulungwane zokujikeleza ngomzuzu kungathinta ukuma kwebhithi lokubhoboza, okuholela ekuphambukeni kobubanzi bemigodi. Izakhiwo zemvelo zokudambisa ngaphakathi kwe-granite ziyenza ikwazi ukumunca ngaphezu kwama-90% okudlidliza kwemishini (20-50Hz). Idatha elinganisiwe ikhombisa ukuthi ngemuva kokufaka isisekelo se-granite, ubukhulu bokudlidliza bebhithi lokubhoboza behle kusuka ku-15μm kuya ku-3μm, kanti inani le-Ra lobunzima bodonga lwemigodi olubhoboziwe lehle ngo-60%, okunciphisa kakhulu izinkinga ze-burrs kanye ne-delamination yodonga lwemigodi.

3. Ukumelana nokuguguleka okuhlala isikhathi eside

Ukubhoboza i-PCB kuwumsebenzi ovame kakhulu futhi unezidingo eziphakeme kakhulu zokumelana nokuguguleka kobuso besisekelo. I-Granite inobulukhuni be-Mohs obungu-6 kuya ku-7 futhi ukumelana kwayo nokuguguleka kuphindwe kathathu kunokwensimbi evamile. Ifektri enkulu ye-PCB ibilokhu isebenzisa izisekelo ze-granite iminyaka emithathu. Ukuguguleka kobuso kungaphansi kuka-0.01mm. Uma kuqhathaniswa nezisekelo zensimbi, umjikelezo wokufaka esikhundleni welulwa kabili, okunciphisa ngempumelelo izindleko zokulungisa imishini.

Ii. Ukuthuthukiswa Kwenqubo: Umklamo owenziwe ngokwezifiso uthuthukisa ukusebenza kahle kokukhiqiza

Izisekelo ze-granite zesimanje, ngokucubungula okunembile kanye nezakhiwo ezintsha, zithuthukisa kakhulu inani lazo lokusebenza:

Ukucubungula okuhlelekile okunembe kakhulu: Ngokusebenzisa ubuchwepheshe bokulawula izinombolo obuhambisana nama-axis amahlanu, ukuba yisicaba kwesisekelo kulawulwa ngaphakathi kuka-±0.5μm/m, okuhlinzeka ngendawo yokubhekisela eyisicaba kakhulu yemishini yokubhoboza nokuqinisekisa ukuthi iphutha lokuma kwe-drill bit lingaphansi kuka-0.01°.

Isakhiwo sokumunca ukushaqeka kwe-honeycomb: Umklamo wangaphakathi we-honeycomb wakha umgodi ozimele, ofinyelela ekunciphiseni amandla okudlidliza ngamazinga amaningi, futhi ufanelekela kakhulu ukucutshungulwa kwe-micro-hole engu-0.1mm noma ngaphansi.

Iziteshi zokupholisa amanzi ezifakwe kusengaphambili: Emishinini yokubhoboza enamandla amakhulu, kufakwa uhlelo lokupholisa amanzi olufakwe ngaphakathi ukuze lulawule umehluko wokushisa ebusweni besisekelo ngaphakathi kuka-±0.5℃, okususa ngokuphelele ingozi yokuguquguquka kokushisa.

Ukuhlelwa kwe-T-slot okwenziwe ngokwezifiso: Isikhala se-T-slot kanye nokunemba (± 0.01mm) kwenziwa ngokwezifiso ngokwemodeli yomshini wokubhoboza ukuze kufezwe indawo esheshayo nokufakwa kwemishini, kunciphisa isikhathi sokusebenza kwedivayisi eyodwa ngo-70%.

Iii. Ubufakazi Bemboni: Ukuthuthukiswa Kokusebenza Kahle Okubonakalayo

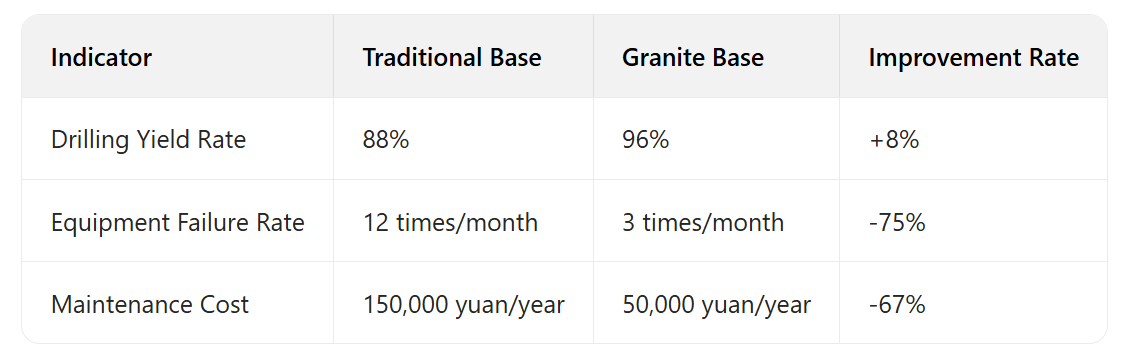

Ngemva kokuba umkhiqizi othile ohamba phambili we-PCB ethule izisekelo ze-granite, idatha yokukhiqiza kwayo ithole ukuthuthuka okuphawulekayo:

Okubaluleke kakhulu, isisekelo se-granite sisize amabhizinisi ukuthi adlule ezinkingeni zobuchwepheshe, aphumelele eku-odeni ama-micro-holes angu-0.2mm noma ngaphansi, futhi avule izimakethe ezinenani eliphezulu.

Iv. Izinzuzo Ezisimeme: Ukukhetha okuhle kakhulu kokukhiqiza okuvikela imvelo

I-Granite iyitshe lemvelo elingenazo izembozo zamakhemikhali futhi ayinazo izingcoliso ze-VOC, ihlangabezana nezindinganiso zokuvikela imvelo ze-RoHS. Isikhathi sayo senkonzo eside kakhulu sinciphisa imvamisa yokushintsha imishini, yehlisa ukusetshenziswa kwezinsiza kanye nokukhishwa kwekhabhoni. Ukubalwa kwenhlangano ethile yokuvikela imvelo kukhombisa ukuthi ukusebenzisa isisekelo se-granite sedivayisi eyodwa yokubhoboza i-PCB kunganciphisa ukukhishwa kwekhabhoni ngamathani ama-3 kuyo yonke imijikelezo yayo yokuphila, okuhambisana nomkhuba wokuguqulwa okuluhlaza embonini yokukhiqiza.

Kusukela ekulawuleni ngokunemba kwezinga le-micron kuya ekwenzeni ngcono izindleko zenqubo egcwele, izisekelo ze-granite zishintsha amazinga ezinqubo zokubhoboza ze-PCB ngezinzuzo zazo zokusebenza ezingenakuguqulwa. Esikhathini samanje sokufunwa okukhulu kwama-chip e-5G ne-AI, ukukhetha isisekelo se-granite akugcini nje ngokutshala imali kwikhwalithi yomkhiqizo kodwa futhi kuyisinyathelo esibalulekile sokuthatha indawo ephezulu yobuchwepheshe.

Isikhathi sokuthunyelwe: Juni-17-2025