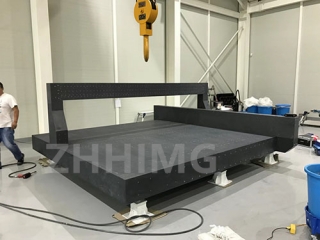

Eshabhu lokukhiqiza le-semiconductor, izidingo zenqubo yokukhiqiza ama-chip zezimo zemvelo kanye nokunemba kwemishini ziphakeme kakhulu, futhi noma yikuphi ukuphambuka okuncane kungaholela ekwehleni okukhulu kwesivuno sama-chip. Ipulatifomu yokunyakaza kwe-gantry ngokunemba kwe-XYZT incike ezingxenyeni ze-granite ukuze zisebenzisane nezinye izingxenye zepulatifomu ukwakha isisekelo esiqinile sokufeza ukunemba kwe-nanoscale.

Izakhiwo ezinhle kakhulu zokuvimba ukudlidliza

Eshabhu lokukhiqiza le-semiconductor, ukusebenza kwemishini yangaphandle kanye nabasebenzi abahambahambayo kungabangela ukudlidliza. Isakhiwo sangaphakathi sezingxenye ze-granite siminyene futhi sifana, sinezici zemvelo eziphakeme zokudambisa, njenge-"vibration" ephumelelayo yokudlidliza. Lapho ukudlidliza kwangaphandle kudluliselwa epulatifomu ye-XYZT, ingxenye ye-granite inganciphisa ngempumelelo amandla angaphezu kuka-80% okudlidliza futhi inciphise ukuphazamiseka kokudlidliza ekunembileni kokunyakaza kwepulatifomu. Ngesikhathi esifanayo, ipulatifomu ifakwe uhlelo lomhlahlandlela wokudlidliza umoya olunembile kakhulu, olusebenza ngokubambisana nezingxenye ze-granite. Umhlahlandlela wokudlidliza umoya usebenzisa ifilimu yegesi ezinzile eyakhiwe yigesi yokucindezela okuphezulu ukuze kufezwe ukunyakaza kokumiswa okungenakuthintana kwezingxenye ezihambayo zepulatifomu futhi kuncishiswe ukudlidliza okuncane okubangelwa ukungqubuzana komshini. Ndawonye, laba ababili baqinisekisa ukuthi ukunemba kokubeka ipulatifomu kuhlala kugcinwa ezingeni le-nanometer ezinqubweni ezibalulekile njenge-chip lithography kanye nokuqopha, futhi kugweme ukuphambuka kwamaphethini wesekethe ye-chip okubangelwa ukudlidliza.

Ukuqina okuhle kakhulu kokushisa

Ukuguquguquka kwezinga lokushisa kanye nomswakama eshabhu kunethonya elikhulu ekunembeni kwemishini yokukhiqiza ama-chip. I-coefficient yokwandisa ukushisa kwe-granite iphansi kakhulu, ngokuvamile ku-5-7 × 10⁻⁶/℃, usayizi awushintshi lapho izinga lokushisa lishintsha. Ngisho noma umehluko wokushisa phakathi kwemini nobusuku eshabhu noma ukukhiqizwa kokushisa kwemishini kubangela ukuthi izinga lokushisa elizungezile lishintshe, izingxenye ze-granite zingahlala zizinzile ukuvimbela ukuguquka kwepulatifomu ngenxa yokwanda nokuncipha kokushisa. Ngesikhathi esifanayo, uhlelo lokulawula izinga lokushisa oluhlakaniphile olufakwe eshabhu luqapha izinga lokushisa elizungezile ngesikhathi sangempela, lulungisa ngokuzenzakalelayo imishini yokupholisa umoya kanye nokusabalalisa ukushisa, futhi lugcina izinga lokushisa leshabhu ku-20 ° C ±1 ° C. Kuhlanganiswe nezinzuzo zokuzinza kokushisa kwe-granite, qinisekisa ukuthi ishabhu lisebenza isikhathi eside, ukunemba kokunyakaza kwe-axis ngayinye kuhlale kuhlangabezana nezindinganiso zokunemba zokukhiqiza ama-chip, ukuqinisekisa ukuthi usayizi wephethini ye-chip lithography unembile, ukujula kokuqopha kuyafana.

Ukuhlangabezana nezidingo zendawo ehlanzekile

Isitolo sokukhiqiza ama-semiconductor sidinga ukugcina izinga eliphezulu lokuhlanzeka ukuze kuvinjelwe izinhlayiya zothuli ukuthi zingangcolisi i-chip. Izinto ze-granite ngokwazo azikhiqizi uthuli, futhi ubuso bubushelelezi, akulula ukumunca uthuli. Ipulatifomu iyonke isebenzisa umklamo wesakhiwo ovaliwe ngokuphelele noma ovalwe kancane ukuze kuncishiswe ukungena kothuli lwangaphandle. Uhlelo lokujikeleza komoya lwangaphakathi luxhunywe nohlelo lokupholisa umoya oluhlanzekile lwe-workshop ukuqinisekisa ukuthi ukuhlanzeka komoya kwangaphakathi kufinyelela ezingeni elidingekayo ekukhiqizweni kwama-chip. Kulesi simo esihlanzekile, izingxenye ze-granite ngeke zithinte ukusebenza ngenxa yokuguguleka kothuli, futhi izingxenye ezibalulekile njengezinzwa ezinembile kakhulu nama-motor epulatifomu nazo zingasebenza ngokuzinzile, zinikeze isiqinisekiso sokunemba kwe-nanoscale okuqhubekayo nokuthembekile ekukhiqizweni kwama-chip, futhi zisize imboni yama-semiconductor ukuthi ifinyelele ezingeni lenqubo ephezulu.

Isikhathi sokuthunyelwe: Ephreli-14-2025