Embonini yezimoto, ukunemba kobukhulu bezingxenye kuthinta ngqo ukusebenza, ukuphepha kanye nokuthembeka kwemoto yonke. Kusukela ezingxenyeni ezibalulekile zenjini kuya ezingxenyeni zokudlulisa ngokunemba, konke ukuphambuka okuncane kobukhulu kungabangela ukusabela kweketanga, okuholela emisindweni engavamile, ukusetshenziswa kukaphethiloli okwandisiwe ngisho nezingozi zokuphepha emotweni. Amathuluzi okulinganisa i-granite, anezakhiwo zawo zomzimba ezihlukile kanye nezinzuzo zobuchwepheshe, abe ngamathuluzi ayinhloko okuqinisekisa ukunemba kobukhulu ekugcineni enkambisweni yokukhiqiza izingxenye zezimoto, ebeka isisekelo esiqinile sentuthuko yekhwalithi ephezulu yemboni yezimoto.

Izinzuzo zemvelo zamathuluzi okulinganisa i-granite: isisekelo sokuqina nokunemba

I-Granite uhlobo lwetshe lemvelo elakhiwe ngezinqubo ze-geological zesikhathi eside. Amakristalu ayo angaphakathi amaminerali aminyene futhi isakhiwo siminyene futhi sifana, okwenza kube nokusebenza okuvelele. Okokuqala, i-granite ine-coefficient ephansi kakhulu yokwanda kokushisa, ngokuvamile kusukela ku-5 kuya ku-7×10⁻⁶/℃. Lesi sici senza ukuthi ingathinteki kakhulu yizinguquko zokushisa. Emashabhu okukhiqiza izingxenye zezimoto, ukushisa okubangelwa ukusebenza kwemishini kanye nokuguquguquka kokushisa kwemvelo kuvamile kakhulu. Amathuluzi okulinganisa enziwe ngezinto ezivamile angabangela amaphutha ngobukhulu ngenxa yokwanda kokushisa kanye nokufinyela, okuthinta ukunemba kokulinganisa. Amathuluzi okulinganisa i-granite angagcina ukuzinza kobukhulu lapho izinga lokushisa lishintsha, aqinisekise ukuthembeka kwedatha yokulinganisa futhi anikeze amazinga okubhekisela anembile okucubungula izingxenye.

Okwesibili, ubulukhuni obuphezulu kanye nokumelana nokuguguleka kwe-granite kungenye inzuzo enkulu yayo. I-granite enobulukhuni be-Mohs obungu-6 kuya ku-7 ayigugi ngesikhathi sokusebenza njalo kokulinganisa. Ukukhiqizwa kwezingxenye zezimoto kuvame ukuhilela inani elikhulu lomsebenzi wokulinganisa ophindaphindwayo. Amathuluzi okulinganisa i-granite angagcina izindawo zokulinganisa ezinembile kakhulu phakathi nokusetshenziswa kwesikhathi eside, anciphise ukuphambuka kokulinganisa okubangelwa ukuguguleka kwamathuluzi, andise impilo yesevisi futhi anciphise izindleko zokufaka amathuluzi ezinkampanini ngesikhathi esifanayo. Ngaphezu kwalokho, i-granite iphinde ibe nokusebenza okuhle kakhulu kokudlidliza, okungamunca ngempumelelo ukudlidliza okubangelwa ukusebenza kwamathuluzi omshini kanye nokuthuthwa kwezinto endaweni yokusebenzela, kunikeze indawo ezinzile yenqubo yokulinganisa, kugwenywe ukuphazamiseka kokudlidliza ngemiphumela yokulinganisa, futhi kuqinisekiswe ukunemba kokuhlolwa kobukhulu.

Ukusetshenziswa okubalulekile kwamathuluzi okulinganisa i-granite ekukhiqizeni izingxenye zezimoto

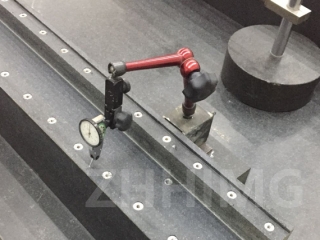

Enqubweni yokukhiqiza injini, amathuluzi okulinganisa i-granite adlala indima ebalulekile. Ukunemba kobukhulu bezingxenye eziyinhloko njenge-engine block kanye ne-cylinder head kuthinta ngqo ukusebenza kahle kokushisa kanye nokukhishwa kwamandla. Ipulatifomu ye-granite, enobukhulu bayo obuphezulu kakhulu (kufika ku-±0.005mm/m), inikeza inkomba enembile yokutholakala kobukhulu be-cylinder block futhi iqinisekisa ukuvalwa kwendawo ngayinye ehlangene. Amabhulokhi e-granite gauge, izitendi ze-dial indicator kanye namanye amathuluzi angalinganisa ngokunembile amapharamitha ayisihluthulelo njengobubanzi bembobo yephini ye-piston kanye nosayizi wejenali ye-crankshaft, elawula ngokuqinile iphutha ezingeni le-micrometer ukuqinisekisa ukunemba kokuhlanganiswa kanye nokuzinza kokusebenza kwenjini.

Amathuluzi okulinganisa i-granite nawo abalulekile ekukhiqizweni kwezingxenye zesistimu yokudlulisa izimoto. Ukunemba kwephrofayili yamazinyo yamagiya okudlulisa, ukuqina kwezingxenye zomgodi kanye nezinye izinkomba kuhlobene ngqo nokushelela kokushintsha kwegiya kanye nokusebenza kahle kokudlulisa kwemoto. Ithuluzi lokulinganisa uhlobo lwesitimela somhlahlandlela we-granite lingaqondisa i-probe yokulinganisa ukuze iskena ngokunembile iphrofayili yamazinyo egiya ngokunemba okuphezulu kakhulu nokuzinza, futhi ukunemba kokuthola amaphutha kungafinyelela ku-±0.002mm. Amabhokisi esikwele e-granite asetshenziselwa ukuthola ukugoba kanye nokulingana kwezingxenye zomgodi, ukuqinisekisa ukunemba kobudlelwano bokuhlanganisa phakathi kwengxenye ngayinye nokuthuthukisa ukuthembeka kohlelo lokudlulisa.

Ngaphezu kwalokho, ngesikhathi senqubo yokukhiqiza izingxenye ze-chassis yezimoto, izidingo zokunemba kobukhulu bezingxenye ezifana nohlelo lokumiswa kanye nohlelo lokuqondisa ziqinile ngokulinganayo. Amathuluzi okulinganisa i-granite alinganisa futhi alawule ngokunembile ubukhulu obufana nobubanzi bembobo, ububanzi besikhala, kanye nobude bezingxenye, ukuqinisekisa ukushintshana kanye nokunemba kokuhlanganiswa kwengxenye ngayinye ye-chassis, futhi anikeze isiqinisekiso sokuzinza nokuphathwa kokusebenza kwemoto.

Khuthaza ukuthuthuka kokukhiqizwa kwezimoto kube ngokunemba okuphezulu

Njengoba imboni yezimoto iqhubekela phambili ekuhlakanipheni nasekufakeni ugesi, izidingo zokunemba kwezingxenye ziya ngokuya ziba nzima. Amathuluzi okulinganisa i-granite, ngokusebenza kwawo okuzinzile kanye nokunemba okuvelele, abe yisikhali esibalulekile samabhizinisi akhiqiza izimoto ukuthuthukisa ikhwalithi yomkhiqizo nokuthuthukisa ukuncintisana emakethe. Ngokusebenzisa amathuluzi okulinganisa i-granite, amabhizinisi angalawula ngokuqinile ubukhulu bezingxenye, anciphise izinga lokulahla, anciphise umjikelezo wokukhiqiza futhi athuthukise ukusebenza kahle kokukhiqiza.

Esikhathini esizayo, ngokuthuthuka okuqhubekayo kobuchwepheshe bokukhiqiza izimoto, amathuluzi okulinganisa i-granite nawo azohlanganiswa ngokujulile nobuchwepheshe bokulinganisa bedijithali kanye nezinhlelo zokuthola ezenzakalelayo, okuthuthukisa kakhulu izinga lobuhlakani kanye nokunemba kokulinganisa. Kusukela ezimotweni zikaphethiloli zendabuko kuya ezimotweni ezintsha zamandla, amathuluzi okulinganisa i-granite azoqhubeka nokuvikela ukukhiqizwa okunembile kokugcina kwezingxenye zezimoto, ekhuthaza imboni yezimoto ukuthi iqhubekele phambili ekuthuthukisweni kwekhwalithi ephezulu.

Isikhathi sokuthunyelwe: Meyi-08-2025