Izingxenye ze-granite mechanical zisetshenziswa kabanzi embonini yesimanje ngenxa yobunzima obungavamile bezinto zemvelo, amandla okucindezela, kanye nokumelana nokugqwala. Ngamasu okusebenza ngokunemba, i-granite iba yindlela engcono kakhulu esikhundleni sensimbi ezinhlobonhlobo zezicelo ze-mechanical, chemical, kanye nezakhiwo.

Lesi sihloko sichaza inqubo yokukhiqiza, izici ezibalulekile, kanye nezimo ezijwayelekile zokusetshenziswa kwezingxenye ze-granite emishinini yezimboni.

Kungani Ukhetha I-Granite Yezingxenye Zemishini?

I-Granite iyidwala eliyi-igneous elivela ngokwemvelo elakhiwe ngokuyinhloko yi:

-

I-Pyroxene

-

I-Plagioclase feldspar

-

I-Minor olivine kanye ne-biotite mica

-

I-Trace magnetite

Ngemva kokuguga ngokwemvelo, i-granite ibonisa ukuthungwa okufanayo, ukubhoboka okuphansi, kanye nokuqina kwesakhiwo okuphezulu—okwenza ifaneleke ukusetshenziswa ezimbonini ngokunemba.

Izinzuzo Eziyinhloko Zezingxenye Zemishini Ye-Granite

1. Ukuqina Okuphezulu Nokumelana Nokugqoka

I-Granite inobulukhuni be-Mohs obungaphezu kuka-6, okwenza imelane kakhulu nokuguguleka. Ilungele izingxenye ezithwala umthwalo omkhulu, ezisheshayo njengezisekelo zamathuluzi omshini, amagiya, kanye neziqondiso eziqondile.

2. Ukumelana Okuhle Kakhulu Kokugqwala

Ngokungafani nezingxenye zensimbi, i-granite imelana ngokwemvelo nama-acid, ama-alkali, nosawoti. Ilungele imishini yokucubungula amakhemikhali, imishini yasolwandle, kanye nezindawo ezigqwalisayo.

3. Amandla Okucindezela Aqinile

Isakhiwo se-granite sivumela ukuthi sikwazi ukumelana nemithwalo ephezulu yemishini ngaphandle kokuguquguquka, okwenza kube kuhle kakhulu ezingxenyeni ezithwala ingcindezi njengezitsha, amakholomu okusekela, kanye nohlaka lomthwalo.

4. Ukuqina Okulinganayo

Njengoba ine-coefficient yokwandisa ukushisa ephansi, i-granite igcina isimo sayo ngaphansi kwezinguquko ezinkulu zokushisa. Ivame ukusetshenziswa ezindaweni ezinembe kakhulu nezinokushisa okuphezulu.

5. Ubuhle Nokusebenza Kahle

Ngenxa yemibala yayo ecebile kanye nobuso obucwebezelayo, i-granite isetshenziswa nasemishinini yokwakha, ezikhumbuzweni, nasezintweni zemishini eziqoshiwe, okuhlanganisa ukusebenza nokukhanga okubonakalayo.

Inqubo Yokukhiqiza Ingxenye Yemishini Ye-Granite

1. Ukukhethwa Kwezinto Ezibalulekile

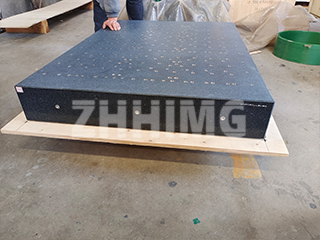

Kukhethwa amabhlogo e-granite kuphela angenamifantu, okusanhlamvu okufanayo, kanye nokucindezeleka okuncane kwangaphakathi. I-granite emnyama ivame ukuthandwa ngenxa yezakhiwo zayo ezishisayo nezisezingeni eliphezulu.

2. Ukusika

I-granite inqunywa ibe amabhlogo aqinile anobukhulu obudingekayo kusetshenziswa ama-diamond wire saw noma ama-blade cutters, kuye ngokuthi ingxenye injani.

3. Ukubumba kanye ne-CNC Machining

Amabhulokhi asikiwe kahle ahlanganiswa abe yizimo zokugcina kusetshenziswa imishini ye-CNC, ama-grinder, noma ukupholisha ngesandla, kuye ngezidingo zokubekezelela. Izingxenye ezifana nezisekelo zomshini noma izindlu zamagiya zidinga ukunemba kwezinga le-micron.

4. Ukwelashwa Komphezulu

Izindawo ziyagaywa kahle, zilolongwe, futhi zipholishwe ukuze kuhlangatshezwane nezidingo zobuchwepheshe. Ezingxenyeni zemishini, lokhu kuqinisekisa ukulingana okuqinile nokuqondana okunembile.

5. Ukuhlolwa Kokugcina

Ingxenye ngayinye ihlolwa ngokulinganisa ubukhulu, ukuhlolwa kwendawo, kanye nokuhlolwa kwesakhiwo ukuqinisekisa ukuhambisana nezindinganiso zomhlaba wonke kanye nezincazelo ezenziwe ngokwezifiso.

Izindawo Eziyinhloko Zokusebenza

1. Ukukhiqiza Amathuluzi Omshini

I-granite ivame ukusetshenziselwa ukukhiqiza izisekelo zomshini we-CNC, ukuhlanganisa imibhede yomshini wokulinganisa, kanye nezindawo zokubopha i-spindle, ngenxa yokuzinza kwayo kanye nokusebenza kwayo kokunciphisa ukudlidliza.

2. Imishini Yobunjiniyela

Amagiya e-granite, imiphini, nezinye izingxenye ezingagugi zilungele imishini yokwakha neyokumba esebenza kanzima.

3. Imishini Yokucubungula Amakhemikhali

Imikhumbi ye-granite, amaphampu, noma izisekelo zamapayipi zinikeza ukumelana okuphezulu kokugqwala ezindaweni ezinolaka zamakhemikhali.

4. Izingxenye Zokwakha Nokuhlobisa

Izingxenye ze-granite mechanical nazo ziyasetshenziswa ekufakweni kwezakhiwo okusezingeni eliphezulu, okuhlanganisa umsebenzi wobunjiniyela nomklamo wobuhle, njengakumakholomu enziwe ngokwezifiso, ama-casing emishini yobuciko, noma izithombe ezibaziweyo zezinga lezimboni.

Isiphetho

Izingxenye ze-granite mechanical zinikeza inhlanganisela enamandla yokuqina, ukunemba, kanye nokumelana nokugqwala, okwenza kube ukukhetha okuhle kakhulu kwezimboni ezifuna ukusebenza okuthembekile ngaphansi kwezimo ezinzima. Ngokuthuthuka komshini we-CNC granite kanye nomklamo we-modular, i-granite iba yindlela esebenzayo neqhubekayo kunezinhlelo zendabuko ze-mechanical ezisekelwe ensimbi.

Isikhathi sokuthunyelwe: Agasti-01-2025