Ipulatifomu ye-granite kanye nepulatifomu yensimbi ephonswe ngensimbi zinezici zazo ngokwezindleko, okufanele kakhulu kuye ngezici ezahlukahlukene, okulandelayo ukuhlaziywa okufanele:

Izindleko zezinto ezibonakalayo

Ipulatifomu yegranite: Igranite yenziwe ngamatshe emvelo, ngokusika, ukugaya nezinye izinqubo. Intengo yezinto zokusetshenziswa zegranite ezisezingeni eliphezulu iphakeme kakhulu, ikakhulukazi igranite ethile engeniswa ngokunemba okuphezulu, futhi izindleko zayo zezinto zibangela ingxenye enkulu yezindleko zepulatifomu yonke.

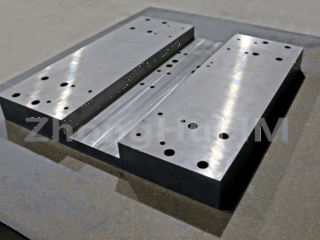

Ipulatifomu yensimbi ephothiwe: Ipulatifomu yensimbi ephothiwe yenziwe kakhulu ngezinto zensimbi ephothiwe, insimbi ephothiwe iyinto evamile yobunjiniyela, inqubo yokukhiqiza isivuthiwe, umthombo wezinto ezibonakalayo ubanzi, izindleko ziphansi kakhulu. Ngokuvamile, izindleko zezinto ezibonakalayo zezincazelo ezifanayo zepulatifomu yensimbi ephothiwe ziphansi kunezepulatifomu yegranite.

Izindleko zokucubungula

Ipulatifomu yegranite: Ubulukhuni begranite buphezulu, ukucubungula kunzima, futhi imishini yokucubungula nezidingo zenqubo ziphezulu. Inqubo yokucubungula idinga ukusetshenziswa kwemishini yokugaya enembile kakhulu namathuluzi ochwepheshe, ukusebenza kahle kokucubungula kuphansi, futhi izindleko zokucubungula ziphezulu. Ngaphezu kwalokho, ukuze kuqinisekiswe ukunemba kanye nekhwalithi yobuso bepulatifomu yegranite, kuyadingeka futhi ukwenza ukugaya nokuhlola okuningi, okwandisa izindleko zokucubungula.

Ipulatifomu yensimbi ephothiwe: izinto zensimbi ephothiwe zithambile, ubunzima bokucubungula buncane, futhi ukusebenza kahle kokucubungula kuphezulu. Izindlela ezahlukahlukene zokucubungula zingasetshenziswa, njengokufaka, ukwenza imishini, njll., futhi izindleko zokucubungula ziphansi kakhulu. Ngaphezu kwalokho, ukunemba kwepulatifomu yensimbi ephothiwe kungalawulwa ngokulungisa inqubo ngesikhathi sokucubungula, futhi asikho isidingo sokwenza ukugaya okuningi okunembe kakhulu njengepulatifomu ye-granite, okunciphisa kakhulu izindleko zokucubungula.

Izindleko zokusebenza

Ipulatifomu yegranite: Ipulatifomu yegranite inokumelana okuhle nokuguguleka, ukumelana nokugqwala kanye nokuqina, akulula ukuyishintsha ngesikhathi sokusetshenziswa, futhi inokugcinwa okuhle kokunemba. Ngakho-ke, impilo yayo yesevisi inde, yize izindleko zokutshalwa kwezimali zokuqala ziphezulu, kodwa ngokuhamba kwesikhathi, izindleko zokusebenzisa ziphansi kakhulu.

Ipulatifomu yensimbi ephothiwe: Ipulatifomu yensimbi ephothiwe isengozini yokuguga nokugqwala ngesikhathi sokusetshenziswa, futhi idinga ukulungiswa nokugcinwa njalo, njengokupenda, ukwelashwa kokulwa nokugqwala, njll., okwandisa izindleko zokusetshenziswa. Futhi ukunemba kwepulatifomu yensimbi ephothiwe akukuhle njengepulatifomu yegranite, ngokwanda kokusetshenziswa kwesikhathi, kungase kube nokuguquguquka nezinye izinkinga, okudingeka zilungiswe noma zishintshwe, kuzokwandisa nezindleko zokusetshenziswa.

Izindleko zokuhamba

Ipulatifomu yegranite: Ubuningi begranite bukhulu, futhi incazelo efanayo yepulatifomu yegranite inzima kakhulu kunepulatifomu yensimbi ephonswe, okuholela ezindleleni zokuhamba eziphakeme. Ngesikhathi sokuhamba, ukupakisha okukhethekile kanye nezinyathelo zokuzivikela nazo ziyadingeka ukuvimbela umonakalo wepulatifomu, okwandisa izindleko zokuhamba.

Ipulatifomu yensimbi ephothiwe: Ipulatifomu yensimbi ephothiwe ilula ngesisindo, futhi izindleko zokuhamba ziphansi. Ngaphezu kwalokho, isakhiwo sepulatifomu yensimbi ephothiwe silula kakhulu, okungelula ukusonakalisa ngesikhathi sokuthuthwa, futhi akudingi izinyathelo ezikhethekile zokupakisha nezokuvikela, okunciphisa izindleko zokuhamba.

Ngamafuphi, maqondana nezindleko, uma kuwukusetshenziswa kwesikhathi esifushane, izidingo zokunemba aziphezulu kakhulu futhi isabelomali sinqunyelwe, ipulatifomu yensimbi ecijile ifaneleka kakhulu, ngoba izindleko zayo zezinto zokwakha, izindleko zokucubungula kanye nezindleko zokuhamba ziphansi kakhulu. Kodwa-ke, uma kuwukusetshenziswa kwesikhathi eside, izidingo zokunemba okuphezulu, isidingo sokuqina okuhle kanye nezikhathi zokumelana nokuguguleka, yize izindleko zokutshalwa kwezimali zokuqala zepulatifomu ye-granite ziphezulu, kodwa ngokombono wezindleko zokusetshenziswa kwesikhathi eside kanye nokuqina kokusebenza, kungaba ukukhetha okonga kakhulu.

Isikhathi sokuthunyelwe: Mashi-31-2025