Emkhakheni wokukhiqiza imishini yezokwelapha, ukubeka kahle kuyisihluthulelo sokuqinisekisa ukunemba kokuxilonga kanye nokuphepha kokwelashwa. Izingxenye zokunemba kwe-granite, ngezakhiwo zazo zomzimba ezihlukile kanye nokusebenza okuvelele, seziba yingxenye ebalulekile nebalulekile yemishini yezokwelapha futhi zisetshenziswa kabanzi emikhakheni eminingi ebalulekile.

Amasimu okusetshenziswa kwezesekeli zokunemba kwe-granite emishinini yezokwelapha

Imishini yokuthwebula izithombe zezokwelapha: Emishinini emikhulu yokuthwebula izithombe zezokwelapha njenge-CT ne-MRI, izingxenye zokunemba kwe-granite zisetshenziselwa ukukhiqiza isisekelo nesakhiwo sokusekela semishini. Lawa madivayisi anezidingo eziphakeme kakhulu zokuzinza. Ngisho nokudlidliza okuncane noma ukufuduka kungabangela ukuthwebula izithombe okufiphele futhi kuthinte imiphumela yokuxilonga. Isakhiwo somswakama ophezulu kanye nesakhiwo esizinzile se-granite kungahlukanisa ngempumelelo ukuphazamiseka kokudlidliza kwangaphandle, kuqinisekiswe ukuthi imishini ihlala izinzile ngesikhathi sokusebenza futhi ngaleyo ndlela kutholakale izithombe ezicacile nezinembile.

Imishini yokwelapha ngemisebe: Imishini yokwelapha ngemisebe idinga ukugxila ngqo emisebeni endaweni yesimila ngenkathi inciphisa umonakalo ezicutshini ezizungezile ezinempilo ngezinga elikhulu. Izesekeli zokunemba kwe-granite zisetshenziselwa ukwenza imibhede yokwelapha kanye namadivayisi okubeka imishini yokwelapha ngemisebe. Ukunemba kwazo okuphezulu kanye nokuqina kwazo kungaqinisekisa ukuthi iziguli zigcina indawo eqondile neqondile ngesikhathi senqubo yokwelapha, okuvumela imisebe ukuthi ikhanyise indawo eqondiwe futhi ithuthukise umphumela wokwelapha.

Amarobhothi okuhlinza: Amarobhothi okuhlinza anezidingo eziphakeme kakhulu zokunemba kokunyakaza kanye nokuzinza. Izinsika zokuqondisa ngokunemba kwe-granite kanye nezilayidi nezinye izesekeli zinganikeza ukunyakaza okubushelelezi nokunembile kwengalo yomshini werobhothi lokuhlinza, okuqinisekisa ukuthi izinsimbi zokuhlinza zingafinyelela ngokunembile endaweni ekhethiwe ngesikhathi sokuhlinza, kufezwe ukusebenza okucwengekile ekuhlinzeni okungangeni kakhulu futhi kuncishiswe izingozi zokuhlinzwa.

Umgomo i-granite efinyelela ngawo indawo eqondile yezinsimbi zezokwelapha

Okokuqala, i-granite ine-coefficient ephansi kakhulu yokwanda kokushisa, ngokuvamile kusukela ku-5 kuya ku-7×10⁻⁶/℃. Imishini yezokwelapha ikhiqiza ukushisa ngesikhathi sokusebenza isikhathi eside, futhi izinga lokushisa elizungezile lingashintsha. Izinto ezijwayelekile zithambekele ekushintsheni kobukhulu ngenxa yokwanda kokushisa kanye nokufinyela, okuthinta ukunemba kokubekwa kwemishini. I-granite cishe ayithinteki yizinguquko zokushisa futhi ingahlala igcina usayizi nesimo esizinzile, ihlinzeka ngesisekelo esiqinile sokuma okunembile kwemishini yezokwelapha.

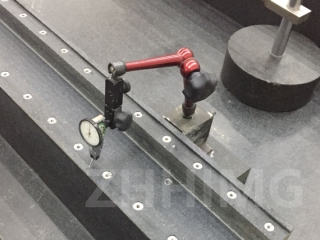

Okwesibili, isakhiwo sangaphakathi se-granite siminyene futhi sifana, futhi siqinile futhi siyamelana nokuguguleka. Ngesikhathi sokusetshenziswa njalo kwemishini yezokwelapha, izingxenye zokunemba kwe-granite azigugi futhi azigugi futhi zingagcina ukusebenza okunembile isikhathi eside. Okwamanje, ukusebenza kwayo okuhle kakhulu kokudlidliza kungamunca ngempumelelo ukudlidliza kwangaphandle, kunciphise ukuphazamiseka kokudlidliza ngesikhathi sokusebenza kwemishini, kuqinisekise ukuzinza kwethuluzi ezindaweni ezahlukahlukene eziyinkimbinkimbi, futhi kufinyelele ekubekweni okunembile.

Ngaphezu kwalokho, ngokusebenzisa amasu okucubungula athuthukile, izesekeli zokunemba kwe-granite zingafinyelela ukunemba okuphezulu kakhulu kokukhiqiza. Ukuthamba okuphezulu kobuso kanye nokulawula ukubekezelelana kobukhulu kwenza ukufakwa kwe-granite kufane kahle nezinye izingxenye zezinsimbi zokwelapha, okuthuthukisa kakhulu ukunemba kokubekwa kwemishini.

Ekuphetheni, izesekeli zokunemba kwe-granite, ngezinzuzo zazo zokusebenza ezihlukile, zidlala indima ebalulekile emkhakheni wemishini yezokwelapha, zinikeza iziqinisekiso ezithembekile zokubekwa okunembile kwemishini yezokwelapha futhi zikhuthaza ukuthuthuka okuqhubekayo kobuchwepheshe bezokwelapha emazingeni aphezulu.

Isikhathi sokuthunyelwe: Meyi-07-2025