Amasu Okufaka Afanele Ama-Granite Precision Bearings

Inqubo yokufaka ama-granite precision bearings idinga ukunakwa ngokucophelela emininingwaneni, njengoba ngisho nokungalungi okuncane kungonakalisa izakhiwo zokunemba zengxenye. Ngaphambi kokuqala noma yikuphi ukufakwa, ngihlala ngincoma ukuthi kwenziwe ukuhlolwa okuphelele kwangaphambi kokufakwa ukuze kuqinisekiswe ubuqotho bengxenye, ukunemba kokuxhumeka, kanye nokusebenza kwezingxenye ezihambayo ezihlobene. Lokhu kuhlola kokuqala kufanele kufake phakathi ukuhlola izindlela zomjaho wama-bearings kanye nezinto ezigoqekayo ukuze kutholakale izimpawu zokugqwala noma umonakalo, ukuqinisekisa ukunyakaza okubushelelezi ngaphandle kokumelana—isinyathelo esivame ukunganakwa kodwa esibalulekile ekuvimbeleni ukuguguleka kwangaphambi kwesikhathi.

Uma ulungiselela ukufaka amabheringi, qala ngokuhlanza zonke izindawo ukuze ususe izembozo noma izinsalela ezivikelayo. Indwangu engena-lint ene-isopropyl alcohol (ukuhlushwa okungu-70-75%) isebenza kahle kakhulu kulo msebenzi, njengoba ihwamuka ngokuphelele ngaphandle kokushiya izinsalela ezingathinta ukubekezelelana kokufakwa. Phakathi nale nqubo yokuhlanza, naka ngokukhethekile izindawo zokubeka amabheringi; noma yiziphi izinhlayiya ezivaleleke phakathi kwezindawo ngesikhathi sokufakwa zingadala amaphuzu okucindezeleka angalingani awona ukunemba ngokuhamba kwesikhathi.

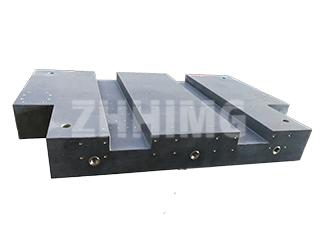

Inqubo yangempela yokufaka idinga ukuphathwa ngokucophelela ukuze kugwenywe ukulimaza izindawo eziphansi ze-granite ngokunemba.

Ukuze uthole ama-bearing anembile, sebenzisa i-lithium-thickened mineral grease (NLGI Grade 2) ezimweni ezijwayelekile noma i-SKF LGLT 2 synthetic grease ezindaweni ezinesivinini esikhulu/ezinokushisa okuphezulu. Gcwalisa ama-bearing ku-25-35% wesikhala samahhala bese wenza i-run-in yesivinini esiphansi ukuze usabalalise i-lubricant ngokulinganayo.

Ukuvikela amabheringi kahle kuhilela ukukhetha amadivayisi afanele okulwa nokukhulula ngokusekelwe ezidingweni zokusebenza. Izinketho zifaka phakathi ama-double nuts, ama-spring washer, ama-split pin, noma ama-lock washer anama-slotted nuts nama-tab washer, ngalinye linikeza izinzuzo ezihlukile ezinhlelweni ezahlukene. Uma uqinisa ama-bolt amaningi, sebenzisa njalo i-crisscross sequence, ukhuphule kancane kancane i-torque kunokuqinisa ngokuphelele i-fastener eyodwa ngaphambi kokushintshela kwenye. Le ndlela iqinisekisa amandla afanayo okubopha azungeze indlu yamabheringi. Ukuze uthole ukuxhumana okude, qala ukuqinisa kusukela maphakathi bese usebenza ngaphandle kuzo zombili izinhlangothi ukuze uvimbele ukugoba noma ukuphambuka kwezindawo zokuhlangana. Umthetho omuhle wesithupha ukushiya iziphetho zentambo zivele ngale kwama-nuts ngezintambo ezingu-1-2 ukuqinisekisa ukuhlangana okugcwele ngaphandle kokuphuma phansi.

Ngemva kokufakwa komshini, inqubo ebalulekile yokuvumelanisa izingxenye ze-granite iyaqala. Usebenzisa izinga le-elekthronikhi noma izinga lomoya oqondile, beka ithuluzi ezindaweni eziningi phezu kobuso ukuze uhlole ukufana. Uma ibhamuza libonakala ngakwesobunxele sendawo ephakathi, uhlangothi lwesobunxele luphakeme; uma ngakwesokudla, uhlangothi lwesokudla ludinga ukulungiswa. Ukuqondanisa okuqondile okuqondile kufezwa lapho ibhamuza lihlala liphakathi kuwo wonke amaphuzu okulinganisa—isinyathelo esithinta ngqo ukunemba kwayo yonke imisebenzi elandelayo yokugaya noma yokulinganisa.

Isigaba sokugcina sokufakwa sihilela ukuqapha ukulandelana kokuqala ukuqinisekisa ukuthi wonke amapharamitha awela ngaphakathi kwamazinga amukelekayo. Izilinganiso ezibalulekile okufanele zibonwe zifaka phakathi ijubane lokujikeleza, ukushelela kokunyakaza, ukuziphatha kwe-spindle, ingcindezi yokugcoba kanye nokushisa, kanye namazinga okudlidliza nomsindo. Ngihlala ngincoma ukugcina i-log yalezi zibalo zokuqala ukuze zibhekwe esikhathini esizayo, njengoba zisungula isisekelo sokusebenza okuvamile. Kuphela uma wonke amapharamitha okuqala ezinza ngaphakathi kokubekezelelana okucacisiwe lapho kufanele uqhubekele ekuhlolweni kokusebenza, okufanele kufake phakathi ukuqinisekiswa kwamazinga okuphakelayo, ukulungiswa kokuhamba, ukusebenza kwendlela yokuphakamisa, kanye nokunemba kokujikeleza kwe-spindle—ukuhlolwa kwekhwalithi okubalulekile okuqinisekisa impumelelo yokufaka.

Imikhuba Ebalulekile Yokulungisa Ukwandisa Isikhathi Sokuphila Sengxenye Yegranite

Nakuba izakhiwo ze-granite ezingokwemvelo zinikeza ukuqina okuhle kakhulu, isikhathi sayo sokuphila isikhathi eside ekusetshenzisweni kokunemba ekugcineni sincike ekusebenziseni izinqubo zokulungisa ezifanele ezivikela ubuqotho besakhiwo sayo kanye nezici zokunemba. Njengoba ngigcine amalabhorethri okulinganisa anezindawo ze-granite iminyaka eminingi, ngithuthukise inqubo yokulungisa ehlala inweba impilo yezingxenye ngale kokuqagela komkhiqizi—ngokuvamile ngo-30% noma ngaphezulu—ngenkathi ngigcina imininingwane yokunemba ebalulekile.

Ukulawulwa kwemvelo kwakha isisekelo sokugcinwa kwezingxenye zegranite okuphumelelayo.

Gcina indawo yokusebenza ku-20±2°C kanye nomswakama ongu-45-55%. Hlanza izindawo usebenzisa i-isopropyl alcohol engu-75% kanye nezindwangu ezithambile ze-microfiber; gwema izihlanzi ezine-acidic. Hlela ukulinganisa kwaminyaka yonke ngama-laser interferometers (isb., i-Renishaw) ukuqinisekisa ukuthi zithambile ngaphakathi kuka-±0.005mm/m.

Lawa mathuluzi okunemba kufanele afakwe ezimweni ezizinzile. Avimbela imijikelezo yokushisa, ukumuncwa komswakama, kanye nokuguguleka kwezinhlayiya okonakalisa ukuqeda kobuso.

Uma izilawuli zingenakugwenywa, sebenzisa izembozo ezivikela ukushisa ngezikhathi ezingasebenzi. Zivikela ekushintsheni kwezinga lokushisa ezindaweni ezisebenzisa imijikelezo yokushisa yansuku zonke.

Imikhuba yokusebenzisa nsuku zonke ithinta kakhulu ukusebenza kwesikhathi eside. Beka njalo izinto zokusebenza ngobumnene ezindaweni ze-granite ukuze ugweme ukulimala kokushayisana.

Ungalokothi ushelele izinto eziqinile phezu kwendawo eqondile nephansi. Lokhu kuvimbela imihuzuko emincane ephazamisa ukunemba kokulinganisa ngokuhamba kwesikhathi.

Okubaluleke ngokulinganayo ukuhlonipha imikhawulo yomthwalo. Ukweqa umthamo olinganisiwe kuyingozi yokulimala okusheshayo kanye nokuguquguquka kancane kancane okuthinta ukunemba.

Ngigcina ishadi lomthamo womthwalo elibekwe eceleni eduze kwendawo ngayinye yokusebenza njengesikhumbuzo esiqhubekayo kubo bonke opharetha.

Ukuhlanza njalo kubalulekile ukuze kulondolozwe izakhiwo ze-granite ezinembile. Ngemva kokusetshenziswa ngakunye, susa yonke imfucumfucu bese usula indawo ngendwangu ethambile.

I-Microfiber isebenza kahle kakhulu ekubambeni izinhlayiya ezincane ngaphandle kokuklwebha. Ukuze uhlanze kahle, sebenzisa insipho ye-pH engathathi hlangothi eyenzelwe izindawo zamatshe.

Gwema amakhemikhali aqinile noma izihlanzi ezihudulayo ezingasusa noma zinciphise ukuqeda. Ithimba lami lisebenzisa i-isopropyl alcohol engu-75% ukususa amafutha ngaphandle kokulimaza izingxenye.

Uma ingasetshenziswa isikhathi eside, indawo yokugcina efanele iba yinto ebalulekile. Hlanza kahle zonke izindawo ngaphambi kokugcina.

Faka ungqimba oluncane lwesivimbeli sokugqwala ezingxenyeni zensimbi. Mboza yonke inhlangano ngesembozo esiphefumulayo nesimelana nothuli.

Ngincoma ukusebenzisa iphakheji yokuqala yokugcina isikhathi eside. Isekela izingxenye ngaphandle kokudala amaphuzu okucindezela angabangela ukugoba.

Ngemisebenzi yesizini, le nqubo yokugcina ivimbela ukuminyana kanye nokucindezeleka okuhlobene nokushisa ngezikhathi zokungasebenzi.

Isici esivame ukunganakwa ukuphinda kulinganiswe ngemva kwanoma yikuphi ukunyakaza. Ngisho nokushintsha indawo encane kungaphazamisa amathuluzi okunemba.

Linganisa kabusha ukuqondanisa okuvundlile usebenzisa amasu e-elekthronikhi noma amazinga e-spirit kusukela ekufakweni kokuqala. Izinkinga eziningi zokunemba zibuyela emuva ezingxenyeni ezingalingani ngemva kokunyakaza.

Hlela isimiso sokuhlola njalo ukuze uthole izinkinga ezingaba khona ngaphambi kokuba zithinte ukusebenza. Ukuhlolwa kwamasonto onke kufanele kufake phakathi ukuhlolwa kwesimo sobuso.

Ukuhlolwa kwekota kungase kuhilele ukulinganisa okuningiliziwe kokusicaba kanye nokulingana kusetshenziswa amathuluzi okunemba. Ukubhala phansi lokhu kudala umlando wokugcinwa.

Lokhu kusiza ukubikezela ukuthi kudingeka nini ukulungiswa kokuvimbela, okuvumela isikhathi sokungasebenzi esihleliwe kunokwehluleka okungalindelekile. Izikhungo ezinokulungiswa kwamatshe ezimboni okusebenzayo zithola impilo yesevisi ende kanye nokusebenza okuthembekile kakhulu ngemishini yazo.

Ukuqina okumangalisayo kobukhulu be-Granite kanye nokumelana nokuguguleka kwenza kube yinto ebaluleke kakhulu ezingxenyeni zemishini enembile. Lezi zinzuzo zitholakala ngokugcwele ngemikhuba efanele yokufaka nokulungisa.

Njengoba sesihlolisisile, ukunaka ngokucophelela ukuhambisana, ukuhlanza, kanye nokulawula imvelo ngesikhathi sokufakwa kusungula isisekelo sokusebenza kwesikhathi eside. Ukugcinwa njalo kulondoloza ukunemba futhi kwandise impilo yesevisi.

Kwabochwepheshe bokukhiqiza abasebenza ngalezi zingxenye ezikhethekile, ukwazi kahle lawa masu kunciphisa isikhathi sokungasebenzi kanye nezindleko zokufaka esikhundleni eziphansi. Aqinisekisa ukulinganiswa okunembile okuthembekile njalo.

Khumbula ukuthi amathuluzi okulinganisa ukunemba kwe-granite amelela ukutshalwa kwezimali okukhulu ekhwalithini yokukhiqiza. Ukuvikela lokho kutshalwa kwezimali ngokunakekelwa okufanele kuqinisekisa ukuthi imishini iletha imiphumela enembile iminyaka ezayo.

Isikhathi sokuthunyelwe: Novemba-19-2025