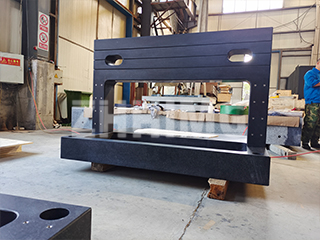

Ipuleti lobuso be-granite, elaziwa nangokuthi ipulatifomu yokuhlola i-granite, liyisisekelo sokubhekisela esinembile kakhulu esisetshenziswa kabanzi ekukhiqizweni kwezimboni, emalabhorethri, nasezikhungweni ze-metrology. Lenziwe nge-granite yemvelo yekhwalithi ephezulu, linikeza ukunemba okuphezulu, ukuzinza kobukhulu, kanye nokumelana nokugqwala, okwenza libe yindawo ekahle kakhulu yezinhlelo zokusebenza zokulinganisa nokulinganisa.

Ukwakheka Kwezinto Nezakhiwo Ezibonakalayo

I-Granite esetshenziselwa amapulatifomu okunemba ngokuvamile iqukethe:

-

I-Pyroxene

-

I-Plagioclase

-

Inani elincane le-olivine

-

I-mica ye-biotite

-

I-Trace magnetite

Lezi zingxenye zamaminerali zinika i-granite umbala omnyama, isakhiwo esiminyene, kanye nokuthungwa okufanayo. Ngemva kokuguga kwemvelo, itshe lifinyelela:

-

Amandla aphezulu okucindezela

-

Ubulukhuni obuhle kakhulu

-

Ukuqina okuphezulu ngaphansi kwemithwalo esindayo

Lokhu kuqinisekisa ukuthi ipuleti elingaphezulu ligcina liyisicaba futhi linembile, ngisho nasezindaweni zezimboni ezidinga kakhulu.

Izindlela Zokusebenzisa Zanamuhla: Ukuthamba Ngaphezu Kwamaphuzu Okuxhumana

Esikhathini esidlule, abasebenzisi babevame ukugcizelela inani lezindawo zokuxhumana lapho behlola amapuleti obuso be-granite. Kodwa-ke, ngosayizi okhulayo kanye nobunzima bezinto zokusebenza, imboni isishintshele ekubekeni phambili ukuthambekela kobuso esikhundleni salokho.

Namuhla, abakhiqizi nabasebenzisi bagxila ekuqinisekiseni ukubekezelelana kokuthamba kunokwandisa izindawo zokuthintana. Le ndlela inikeza:

-

Ukukhiqizwa okungabizi kakhulu

-

Ukunemba okwanele kwezicelo eziningi zezimboni

-

Ukuzivumelanisa nezimo kwezingxenye zokusebenza ezinkulu kanye nemishini

Kungani Ukhetha I-Granite Yezicelo Zokulinganisa?

1. Ukuqina Okulinganayo

I-granite idlula eminyakeni eyizigidi yokuguga kwemvelo, isusa ukucindezeleka kwangaphakathi. Umphumela uba yinto ezinzile, engaguquki efanelekile ukusetshenziswa isikhathi eside ezindaweni ezinembile.

2. Ukumelana Kwamakhemikhali Nokune-Magnetic

I-granite imelana nama-acid, ama-alkali, ukugqwala, kanye nokuphazamiseka kwamagnetic, okwenza ifaneleke ezindaweni zokugcina amakhemikhali, amakamelo okuhlanza, kanye nokukhiqizwa kobuchwepheshe obuphezulu.

3. Ukwanda Okuphansi Kokushisa

Njengoba i-coefficient yokwandisa ukushisa iphakathi kuka-4.7 × 10⁻⁶ kuya ku-9.0 × 10⁻⁶ intshi/intshi, izindawo ze-granite zithinteka kancane yizinguquko zokushisa, okuqinisekisa ukufundwa okunembile ezimweni eziguquguqukayo.

4. Ivikela umswakama futhi ayinawo umhlwa

Ngokungafani nezinye izindlela zensimbi, i-granite ayithinteki emswakama futhi ayisoze yagqwala, okuqinisekisa ukuthi ayinakekelwa kahle futhi ihlala isikhathi eside.

5. Ukuqina Okuphezulu Nokumelana Nokugqokwa

Njengenye yezinto zokwakha eziqinile kakhulu, i-granite inikeza ukumelana okuhle kakhulu nokuguguleka, ngisho noma isetshenziswa njalo.

6. Ukuqeda Okubushelelezi Komphezulu

Ubuso bungagaywa kahle futhi bupholishwe, kuhlinzeke ngokuqedwa okufana nesibuko okuqinile okuqinisekisa ukuthintana kahle nezingxenye ezilinganisiwe.

7. Ukubekezelelana Komthelela

Uma ubuso buklwebheka noma bushaywa, i-granite ivame ukuba nezimbobo ezincane kunokuba kube nezimbobo noma imiphetho ephakanyisiwe—ukugwema ukuphambuka ekulinganisweni okubucayi.

Izinzuzo Ezengeziwe Zamapuleti Okuhlola I-Granite

-

Okungeyona i-magnetic futhi okulwa nokungaguquguquki

-

Kulula ukuhlanza nokunakekela

-

Inobungani nemvelo futhi yakhiwe ngokwemvelo

-

Itholakala ngamamaki nobukhulu obuhlukahlukene

Isiphetho

Ipuleti lobuso le-granite liyaqhubeka liyithuluzi eliyisisekelo ezimbonini zanamuhla zokunemba. Ngokunemba kwalo okulinganiselwe, ukuzinza kwesikhathi eside, kanye nokumelana nezici zemvelo, lisekela izinhlelo zokusebenza ezisukela ekusetshenzisweni kwe-CNC kuya ekulawulweni kwekhwalithi kwezobuchwepheshe, izindiza, kanye nokusetshenziswa kwezinsimbi.

Njengoba ubukhulu bezinto zokusebenza kanye nobunzima bokuhlola bukhula, amapuleti obuso be-granite ahlala eyisisombululo esithembekile nesingabizi kakhulu sokugcina amazinga okulinganisa aphezulu kakhulu.

Isikhathi sokuthunyelwe: Agasti-01-2025