Izinhlelo zokumetha ngokunemba zakha umgogodla wokulawulwa kwekhwalithi yokukhiqiza yesimanje. Njengoba ukubekezelelana kuqina futhi ubunzima bezingxenye bukhula, ukunemba nokuzinza kwemishini yokulinganisa kuye kwaba yizinto ezibalulekile zokuncintisana kubakhiqizi emhlabeni wonke. Enhliziyweni yalezi zinhlelo eziningi kukhona amapuleti obuso be-granite nezakhiwo ezisekelwe ku-granite, ezihlinzeka ngamajiyometri okubhekisela azinzile okuhlolwa kobukhulu kanye nokulinganisa okuhlelekile.

EYurophu naseNyakatho Melika, isidingo sabakhiqizi bamapuleti obuso be-granite abasebenza kahle kakhulu sikhule kancane kancane kanye nokwanda kokukhiqizwa kwe-semiconductor, ukukhiqizwa kwezindiza, kanye nokwenza izinto ngokuzenzakalela okuthuthukisiwe. Lesi sihloko sihlola indima yabakhiqizi bamapuleti obuso be-granite ngaphakathi kwe-precision metrology ecosystem, sihlola ukusetshenziswa okubalulekile kwe-granite emishinini yokulinganisa ehlanganisiwe (ama-CMM), futhi sichaza ukuthi i-granite isekela kanjani ukusebenza kwezinhlelo zesimanje ze-precision metrology.

Abakhiqizi Bepuleti Lomphezulu Wegranite: Okulindelwe Emakethe Nezidingo Zobuchwepheshe

Amapuleti obuso be-granite ayizinto eziyisisekelo ku-metrology enobukhulu. Ahlinzeka ngezindawo zokubhekisela ezisicaba nezizinzile zokuhlola, ukulinganisa, kanye nemisebenzi yokuhlanganisa. Kodwa-ke, akubona bonke abakhiqizi bepuleti lobuso be-granite abanikeza izinga elifanayo lokusebenza noma ukuhambisana.

Abakhiqizi bekhwalithi ephezulu bagxila ekukhetheni izinto njengento ehlukanisayo eyinhloko. I-granite emnyama yekhwalithi ephezulu enesakhiwo esifanayo sokusanhlamvu kanye nobuningi obuphezulu inikeza ukuzinza okuphezulu kobukhulu kanye nokumelana nokuguguleka. Izinto eziphansi zingahlangabezana nezidingo zokuqala zokusicaba kodwa zingabonisa ukukhukhuleka kwesikhathi eside noma ukuguguleka kwendawo ngaphansi kokusetshenziswa okuqhubekayo.

Amandla okukhiqiza nawo abaluleke kakhulu. Ukugaya nokugoqa ngokunemba kumele kwenziwe ezindaweni ezilawulwa amazinga okushisa ukuze kufezwe ukuthamba kanye nokuqondile kwezinga le-micron. Abakhiqizi bepuleti lobuso be-granite abadumile nabo bagcina izinhlelo zokuhlola eziqinile, okuhlanganisa i-laser interferometry kanye nezinsimbi zokubhekisela ezilinganisiwe, ukuqinisekisa ukuhambisana nezindinganiso zomhlaba wonke.

Kumakhasimende aseYurophu naseNyakatho Melika, ukulandeleka, ukubhalwa kwamadokhumenti, kanye nekhwalithi ehambisanayo kubalulekile. Amapuleti angaphezulu avame ukufakwa ezinhlelweni zekhwalithi eziqinisekisiwe, okwenza ukunemba kwesikhathi eside kanye nokuqina kokulinganisa kabusha kube yizindlela zokuhlola ezibalulekile lapho kukhethwa umhlinzeki.

Ukusetshenziswa kweGranite kuMishini Yokulinganisa Ehlanganisiwe (ama-CMM)

Imishini yokulinganisa ehlanganisiwe imelela enye yezicelo ezidinga kakhulu izingxenye ze-granite ezinembile. Kuma-CMM, i-granite ayikhawulelwe kumapuleti angaphezulu kuphela, kodwa isetshenziswa kabanzi njengezinto zokwakha kuwo wonke umshini.

I-Granite njengeSakhiwo Sesisekelo se-CMM

Isisekelo se-CMM kumele sinikeze ukuqina okungavamile kanye nokuqina kokushisa ukuze kusekelwe ukulinganisa okunembile okunezinhlangothi ezintathu. Izisekelo ze-granite zinikeza ukwanda okuphansi kokushisa kanye nokunciphisa ukudlidliza okuhle kakhulu, okunciphisa ukungaqiniseki kokulinganisa okubangelwa izinguquko zemvelo noma ukuphazamiseka kwangaphandle.

Ngokungafani nezakhiwo zensimbi ezishisiwe noma ezibunjiwe, izisekelo zegranite azinawo ukucindezeleka okusele, okuzivumela ukuthi zilondoloze ubuqotho bejometri isikhathi eside. Lokhu kwenza igranite ibe yinto efanelekile kokubili imiklamo ye-CMM yohlobo lwebhuloho kanye ne-gantry.

Amabhuloho Namakholomu E-Granite

I-granite isetshenziselwa futhi amabhuloho, amakholomu, kanye nezakhiwo zendlela yokuqondisa ngaphakathi kwe-CMM. Lezi zingxenye kumele zigcine ukuhambisana okunembile ngaphansi kokunyakaza okuguquguqukayo ngenkathi zisekela izinto ezihambayo njengezinhlelo zokuhlola kanye nezinqola. Izici zokunciphisa umswakama ezitholakala ngaphakathi kwe-granite zithuthukisa ukuzinza kwesistimu futhi zinciphise isikhathi sokuhlala ngesikhathi semijikelezo yokulinganisa.

Ukuhlanganiswa nama-Air Bearings nama-Linear Drives

Ama-CMM amaningi aphezulu asebenzisa ama-air bearings nama-linear motors ukuze afinyelele ukunyakaza okubushelelezi nokuphansi kokungqubuzana. Izindawo ze-granite zinikeza izindiza ezinhle kakhulu zokubhekisela ezinhlelweni zokuthwala umoya, zisekela ukuziphatha kwefilimu yomoya okuqhubekayo kanye nokunemba kokubekwa okuphindaphindwayo. Lokhu kuhlanganiswa kuthuthukisa ukusebenza okuphelele kwezinhlelo zokulinganisa ngokunemba.

I-Granite kuzinhlelo ze-Modern Precision Metrology

Ngaphandle kwama-CMM endabuko, i-granite idlala indima ebalulekile ezinhlobonhlobo zezinhlelo ze-precision metrology. Amapulatifomu okulinganisa okubonakalayo, ukusethwa kwe-laser interferometer, kanye nemishini yokulinganisa ifomu konke kuncike ezisekelweni zesakhiwo ezizinzile ukuze kutholakale imiphumela ethembekile.

Amapuleti ongaphezulu kwe-granite avame ukusetshenziswa njengezingxenyekazi eziyisisekelo zama-comparators optical, izinhlelo zokulinganisa umbono, kanye nemishini ye-hybrid metrology. Izakhiwo zawo zokudambisa ukudlidliza zisiza ukuhlukanisa izinqubo zokulinganisa ezibucayi ekuphazamisekeni kwendawo ezindaweni zokukhiqiza.

Emigqeni yokuhlola ezenzakalelayo, izakhiwo ezisekelwe ku-granite zisekela iziteshi zokulinganisa ezingaphakathi ezisebenza njalo. Ukuqina kwesikhathi eside kwe-granite kunciphisa isidingo sokulungiswa kabusha njalo, kuthuthukiswe isikhathi sokusebenza futhi kuncishiswe izindleko eziphelele zobunikazi.

Izitayela Zemboni Ezibangela Isidingo Sezixazululo Ze-Metrology Ezisekelwe Ku-Granite

Izitayela eziningana zemboni zinegalelo ekwandeni kwesidingo samapuleti ongaphezulu e-granite kanye nezingxenye ze-metrology ezisekelwe ku-granite. Ukukhiqizwa kwe-semiconductor kuyaqhubeka nokucindezela izidingo zokulinganisa ebangeni le-sub-micron kanye ne-nanometer, okwandisa ukuthembela ezakhiweni zemishini ezizinzile kakhulu.

Ngesikhathi esifanayo, izimboni zezindiza nezimoto zamukela amajiyometri ayinkimbinkimbi kakhulu kanye nokubekezelelana okuqinile, okudinga amakhono okuhlola athuthukile. Izinhlelo zokulinganisa ngokunemba ezakhiwe ezisekelweni ze-granite zinikeza ukuzinza okudingekayo ukuze kuhlangatshezwane nalezi zinselele.

Ukuzenzakalela kanye nokukhiqizwa kwedijithali kuyayikhulisa le mfuno. Njengoba izinhlelo zokulinganisa zihlanganiswa ngqo emigqeni yokukhiqiza, ukuzinza kwesakhiwo kanye nokuqina kwemvelo kuba yizinto ezibalulekile ezicatshangelwayo zokuklama.

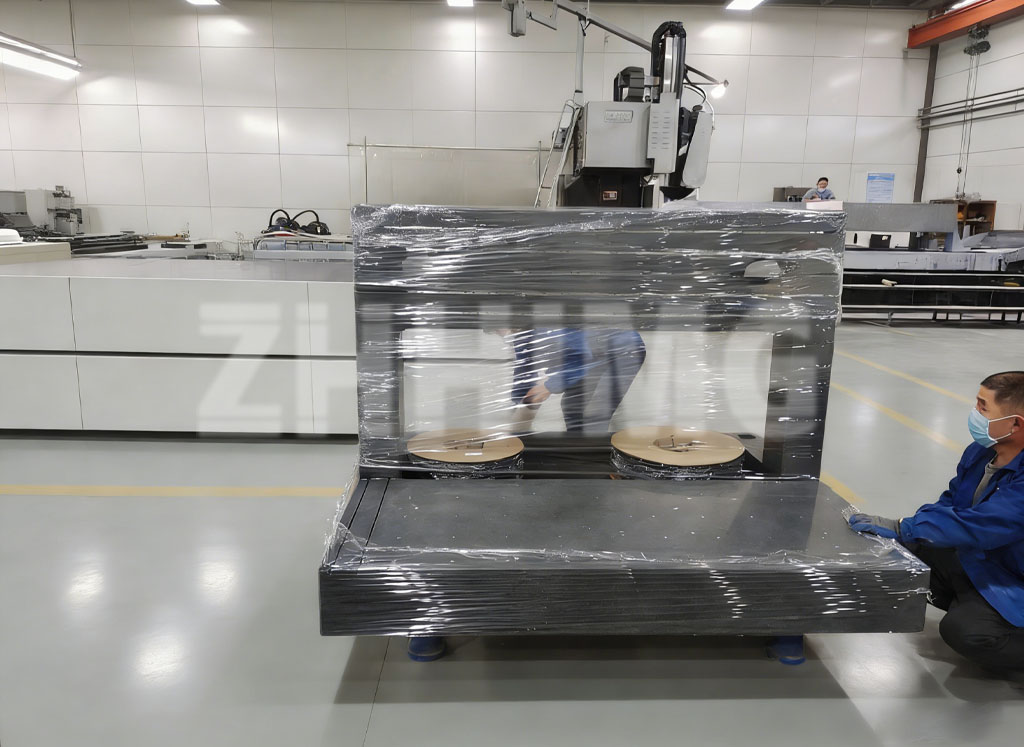

Amakhono e-ZHHIMG njengomkhiqizi we-Precision Granite

I-ZHHIMG ingumkhiqizi onolwazi lwe-izingxenye ze-granite ezinembileukukhonza amakhasimende omhlaba wonke ku-metrology kanye nokukhiqiza okuthuthukisiwe. Ngokuhlanganisa izinto ze-granite zekhwalithi ephezulu nobuchwepheshe bokugaya nokuhlola obuthuthukisiwe, i-ZHHIMG iletha amapuleti obuso be-granite kanye nezakhiwo ze-CMM ezihlangabezana nezindinganiso eziqinile zokunemba zomhlaba wonke.

Amakhono enkampani afaka phakathi amapuleti asezingeni eliphezulu e-granite ajwayelekile nangokwezifiso, izisekelo ze-granite ze-CMM, izakhiwo zamabhuloho nezindawo zokubeka izindonga, kanye nezixazululo ze-granite eziqondene nesicelo sezinhlelo ze-metrology ezinembile. Ingxenye ngayinye ikhiqizwa ngaphansi kwezimo ezilawulwayo futhi iqinisekiswe ngokuhlolwa kwekhwalithi okuphelele.

Ngokubambisana okuseduze nabakhiqizi bemishini kanye nochwepheshe be-metrology, i-ZHHIMG isekela ukuhlanganiswa kwesistimu okuthembekile kanye nokusebenza kwesikhathi eside kuzo zonke izinhlelo zokusebenza zokulinganisa ngokunemba.

Isiphetho

Amapuleti obuso be-granite kanye nezakhiwo ezisekelwe ku-granite zihlala ziyizingxenye ezibalulekile ngaphakathi kwezinhlelo zesimanje zokukala ngokunemba. Kusukela ezinhlotsheni zokubhekisela eziyisisekelo kuya ezakhiweni ze-CMM eziphelele, i-granite inikeza ukuzinza, ukufiphaza, kanye nokuqina okudingekayo ukusekela ukulinganiswa okunembile kobukhulu.

Njengoba izimboni ziqhubeka nokuthuthuka zibheke ekuqondeni okuphezulu kanye nokwenza izinto ngokuzenzakalelayo okukhulu, indima yabasebenzi abanekhonoipuleti lobuso begraniteabakhiqizi bazoba ngababaluleke kakhulu. Ngobuchwepheshe obuzinikele ekukhiqizeni i-granite ngokunemba, i-ZHHIMG isesimweni esihle sokusekela izidingo ezishintshayo zezimakethe zomhlaba wonke ze-metrology kanye nokuhlolwa.

Isikhathi sokuthunyelwe: Jan-21-2026