Ekukhiqizeni ngokunemba kwanamuhla, ukukhetha isisekelo somshini kubalulekile ekufinyeleleni ukunemba okuphezulu, ukuzinza, kanye nokuthembeka kwesikhathi eside. Izimboni ezisukela ekukhiqizweni kwe-semiconductor kuya kuma-optics anembile kakhulu zithembela kakhulu ezisekelweni ezihlinzeka ngokusebenza kwesakhiwo okuhambisanayo. Phakathi kwezinto okuxoxwa ngazo kakhulu kulo mongo kukhona i-granite ne-cast iron. Ngayinye inezakhiwo zomzimba ezihlukile, izinzuzo, kanye nemikhawulo ethinta ukwakheka kwesistimu, ukugcinwa, kanye nezindleko zomjikelezo wokuphila.

Lesi sihloko sihlola umehluko phakathi kwezisekelo zomshini we-granite kanyeizisekelo zomshini wensimbi ephonswe, iqokomisa abakhiqizi bemishini ye-granite abaphambili, futhi ihlola ukucatshangelwa kwemishini enembile ekusetshenzisweni kwezimboni zanamuhla. Ingxoxo ikhombisa izitayela eYurophu naseNyakatho Melika futhi ihambisana nokuziphatha kokusesha okuvela kochwepheshe bobunjiniyela kanye nokuthengwa kwempahla abafuna isiqondiso sobuchwepheshe esithembekile.

Indima Yezisekelo Zomshini Oqondile

Isisekelo somshini onembile singaphezu nje kwesakhiwo sokusekela—sichaza i-geometry yokubhekisela yezinhlelo zokunyakaza, izinsimbi zokulinganisa, kanye nemisebenzi yokusika noma yokuhlanganisa. Ukuqina, ukuziphatha kokushisa, kanye nezici zokunciphisa ukudlidliza kwesisekelo kuthinta ngqo ukusebenza kwesistimu kanye nokuphindaphinda kokulinganisa.

Imisebenzi Eyinhloko

- Ukusekelwa Kwesakhiwo:Inikeza ukuqina kwezingxenye ezifakiwe futhi iqinisekisa ukuzinza kobukhulu ngaphansi komthwalo.

- Ukudambisa Ukudlidliza:Kunciphisa ukudluliselwa kokudlidliza kwemvelo noma kokusebenza ezingxenyeni ezibucayi.

- Ukuzinza Kokushisa:Kunciphisa ukunwebeka noma ukufinyela ngokushintsha kwezinga lokushisa ukuze kulondolozwe ukuhambisana nokulinganiswa.

- Ubude besikhathi:Iqinisekisa ukusebenza okulinganayo phakathi nezikhathi zesevisi ezinde ngaphandle kokulungiswa okuningi.

Ukuqonda le misebenzi kusiza onjiniyela ukuthi bahlole izinketho zezinto ezibonakalayo futhi bathuthukise umklamo womshini.

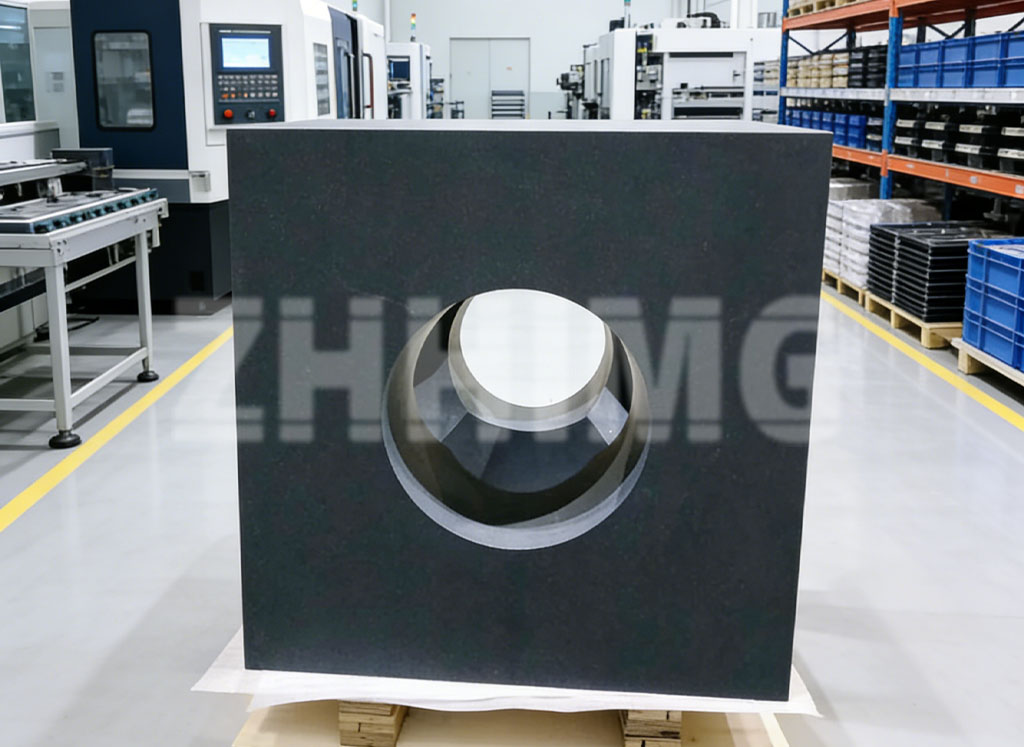

Izisekelo Zomshini Wegranite: Izakhiwo Nezinzuzo

I-granite ibilokhu iyinto ethandwayo kakhulu yezisekelo ezinembile kakhulu, ikakhulukazi e-imishini yokulinganisa edidiyelwe (ama-CMM), izinhlelo ze-laser, kanye namapulatifomu okuhlola okukhanya.

Izakhiwo Ezibonakalayo

- Ukwanda Okuphansi Kokushisa:I-Granite ibonisa ushintsho oluncane kakhulu lobukhulu ngokushintshashintsha kwezinga lokushisa, okufaka isandla ekuhleleni okuzinzile.

- Ubuningi Obukhulu:Ubukhulu bayo obungokwemvelo bunciphisa ukudlidliza ngempumelelo.

- Ukuziphatha Okungashisi Kahle:Izakhiwo zomzimba ezifanayo kuzo zonke izinhlangothi zinciphisa ukugoba noma ukugoba ngaphansi komthwalo.

- Ukumelana Nokugqwala:Ngokungafani nensimbi, i-granite ayivuthisi noma yonakale, okudinga ukwelashwa okuncane noma okungenasivikelo.

Izinzuzo kuzinhlelo zokusebenza eziqondile

- Ukudambisa Ukudlidliza:I-Granite imunca ngokwemvelo ukudlidliza okuvama kakhulu, ithuthukisa ukulinganisa kanye nokuphindaphinda kwenqubo.

- Ukuzinza Kwesikhathi Eside:Igcina isicaba futhi iqondile amashumi eminyaka ngaphandle kokunakekelwa okuningi.

- Ukunemba Okulinganayo:Ilungele izinhlelo zokusebenza ezidinga ukubekezelelana okuqinile kuma-micron.

Abakhiqizi Abahamba phambili

Abakhiqizi bemishini ye-granite bangochwepheshe ekuhlanganiseni ngokunemba okuphezulu,ukuqedwa kobuso, kanye nezinqubo zokulawula ikhwalithi ukuletha amapulatifomu aqondile nazinzile. Abahlinzeki abahamba phambili emhlabeni wonke bafaka izinkampani ezinezitifiketi ze-ISO 9001, ISO 14001, kanye ne-CE eziqinisekisa ukukhethwa kwezinto ezihambisanayo, amazinga okusebenza, kanye nokuhlola.

Izisekelo Zomshini Wensimbi Ebunjiwe: Izakhiwo Nezicelo

Insimbi ephothiwe ibilokhu iyinsika yokwakhiwa kwamathuluzi omshini wendabuko futhi isalokhu ivamile ekusetshenzisweni okudinga ukuqina okuphezulu kanye nomthamo womthwalo.

Izakhiwo Ezibonakalayo

- I-Coefficient Ephakeme Yokwanda Kokushisa:Izwela kakhulu ekushintsheni kwezinga lokushisa uma kuqhathaniswa ne-granite.

- Ukumanzisa Okumaphakathi:Ukufakwa kwe-graphite ku-grey cast iron kunikeza ukumuncwa okuthile kokudlidliza, kodwa kuncane kune-granite.

- Ukuqina Okuphezulu:Ukumelana okuhle kakhulu nokugoba kanye nokuguqulwa ngaphansi kwemithwalo esindayo.

Izinzuzo kanye Nezimo Zokusebenzisa

- Izicelo Ezinzima:Ilungele kahle amathuluzi omshini,Imishini yokugaya ye-CNC, kanye nezinhlelo ezinkulu zezimboni.

- Ukuphumelela Kwezindleko:Ngokuvamile izindleko zezinto zokwakha ziphansi uma kuqhathaniswa ne-granite yezinga eliphezulu.

- Ukusebenziseka kalula:Ingafakwa kalula kuma-geometri ayinkimbinkimbi futhi ihlanganiswe nezici zemishini.

Ukulinganiselwa

- Ukuzwela Kokushisa:Kudinga ukulawulwa kwemvelo noma isinxephezelo esisebenzayo emisebenzini enembile kakhulu.

- Izidingo Zokulungisa:Ingathinteka ukugqwala; ingadinga ukulungiswa kabusha njalo ukuze kugcinwe ukunemba.

Ukuhlaziywa Kokuqhathanisa: I-Granite vs Iron Ephothiweyo

| Isici | I-Granite | Insimbi |

|---|---|---|

| Ukwanda Kokushisa | Okuphansi; ukuzinza okuhle kakhulu | Phezulu; zizwela izinguquko zokushisa |

| Ukudambisa Ukudlidliza | Kuhle kakhulu | Okumaphakathi |

| Umthamo Wokulayisha | Okumaphakathi; kuncike ku-geometry | Okuphezulu; kusekela imishini esindayo |

| Ukulungiswa | Okuncane | Kudinga ukuvikelwa nokugcinwa njalo |

| Isikhathi Sokuphila | Iminyaka eminingi ngokusebenza okulinganayo | Isikhathi eside, kodwa singawohloka ngaphansi kokugqwala noma ukucindezeleka kokushisa |

| Izicelo Ezijwayelekile | I-CMM, izinhlelo ze-laser, amabhentshi optical | Imishini ye-CNC, amathuluzi amakhulu ezimboni |

Imiphumela Yabaklami

I-granite iyathandwa lapho ukudambisa ukudlidliza, ukuzinza kokushisa, kanye nokunemba okuphezulu kuyizinto eziza kuqala. Insimbi ephothiweyo ihlala ifaneleka emisebenzini enzima lapho ukuqina kanye nomthamo wokuthwala umthwalo kubaluleke kakhulu kunokuqina kwezinga le-micrometer ngokuphelele.

Ukukhetha Isisekelo Somshini Oqondile Ofanele

Onjiniyela kumele bahlole izici eziningana lapho bekhetha phakathi kwezisekelo ze-granite nezinsimbi eziphonswe ngensimbi:

- Izidingo Zohlelo Lokusebenza:Nquma ukunemba okudingekayo, umthwalo, kanye nezimo zemvelo.

- Izinto Okucatshangelwe Kubhajethi:Linganisa izindleko zezinto zokwakha nezinzuzo zokusebenza kanye nokugcinwa komjikelezo wokuphila.

- Ukuhlanganiswa Kwesistimu:Cabanga ngokuhambisana nezigaba zokunyakaza, izinzwa, kanye nemishini yokusiza.

- Ubuchwepheshe Bomhlinzeki:Sebenzisana nabakhiqizi abanolwazi ukuqinisekisa ikhwalithi kanye nokuhambisana nezindinganiso zokunemba.

Izifundo Zamacala kanye Nezibonelo Zemboni

Imishini Yokulinganisa Ehlanganisiwe (ama-CMM)

Izisekelo ze-granite zijwayelekile kuma-CMM anembe kakhulu ngenxa yokuqina kwawo kanye nokumelana nokuguguleka. Izisekelo zensimbi ephothiwe zingasetshenziswa ezinhlelweni ezinkulu, ezingabalulekile lapho kulindeleke khona imithwalo ephezulu.

Izinhlelo Zokusika Nezokulinganisa I-Laser

Izisekelo ze-granite zihlinzeka ngokudambisa ukudlidliza okubalulekile ekucutshungulweni kwe-laser, ukuthuthukisa ikhwalithi yokusika kanye nokunciphisa amaphutha ekusetshenzisweni kwezinga elincane.

Amathuluzi Omshini

Insimbi ephothiweyo isalokhu iyisinqumo esivelele samapulatifomu okugaya nokulungisa lapho izinto zokusebenza ezisindayo namandla okusika aphezulu zidinga ukuqina okukhulu kanye nokuqina kwesakhiwo.

Isiphetho

Zombili izisekelo zomshini we-granite kanye ne-cast iron zidlala indima ebalulekile ekukhiqizeni ngokunemba. I-granite ihamba phambili ezinhlelweni zokusebenza ezidinga ukuzinza okukhulu, ukudambisa ukudlidliza, kanye nokuvumelana kokushisa, okwenza ibe yindawo efanele ama-CMM, izinhlelo ze-laser, kanye ne-optical metrology. I-cast iron ifaneleka kangcono kumathuluzi omshini asebenza kanzima lapho ukuqina kanye nomthamo womthwalo kubusa khona.

Ukusebenzisana nabakhiqizi bemishini ye-granite abanolwazi kuqinisekisa ukuthi izidingo zokunemba ziyahlangatshezwana ngenkathi kunciphisa ukugcinwa kwesikhathi eside. Ngokuhlola ngokucophelela izidingo zohlelo lokusebenza, izimo zemvelo, kanye nezakhiwo zezinto ezibonakalayo, onjiniyela bangakhetha isisekelo esifanele kakhulu ukuze bandise ukusebenza nokuthembeka kwemishini yokunemba.

Isikhathi sokuthunyelwe: Jan-23-2026