Emkhakheni wokulinganisa ngokunemba, umshini wokulinganisa ohlanganisa izinto ezintathu uwumshini oyinhloko wokulawula ikhwalithi yomkhiqizo, futhi isisekelo sisebenza njengesisekelo sokusebenza kwawo okuzinzile. Ukusebenza kwawo kokuguquguquka kokushisa kunquma ngqo ukunemba kokulinganisa. I-granite nensimbi ephonswe, njengezinto ezimbili eziyisisekelo eziyinhloko, sekuyisikhathi eside kudonsela ukunaka okukhulu ngomehluko wazo ekuguqukeni kokushisa. Ngobuchwepheshe bokubona ngeso lengqondo kwabathwebuli bezithombe zokushisa, singaveza ngqo umehluko obalulekile ekuzinzeni kokushisa phakathi kwalokhu okubili, sinikeze isisekelo sesayensi sokukhethwa kwemishini embonini yokukhiqiza ngokunemba.

Ukuguqulwa kokushisa: "Umbulali Ongabonakali" Othinta Ukunemba Kokulinganisa Okunezinhlangothi Ezintathu

Umshini wokulinganisa ohlanganisa izinto ezintathu uthola idatha enobukhulu obuthathu ngokuxhumana kweprobe nento elinganiswayo. Noma yikuphi ukuguqulwa kokushisa kwesisekelo kuzokwenza ukuthi ireferensi yokulinganisa ishintshe. Endaweni yezimboni, izici ezifana nokukhiqizwa kokushisa ngesikhathi sokusebenza kwemishini kanye nokushintshashintsha kokushisa kwemvelo konke kungabangela ukwanda kokushisa noma ukufinyela kwesisekelo. Ukuguqulwa kokushisa okuncane kungabangela ukuphambuka kwesimo kuprobe yokulinganisa, ekugcineni kuholele emaphutheni okulinganisa. Ezimbonini ezinezidingo zokunemba okuphezulu kakhulu njengezindiza kanye nama-semiconductor, amaphutha abangelwa ukuguqulwa kokushisa angaholela ekulahlekelweni komkhiqizo noma ekuwohlokeni kokusebenza. Ngakho-ke, ukuzinza kokushisa kwesisekelo kubaluleke kakhulu.

Isithombe se-Thermal: Sibona ngeso lengqondo umehluko ekuguqulweni kwe-thermal

Abathwebuli bezithombe ezishisayo bangaguqula ukusatshalaliswa kwezinga lokushisa ebusweni bento kube yizithombe ezibonakalayo. Ngokuhlaziya izinguquko zokushisa ezindaweni ezahlukene, bangaveza ngokubonakalayo isimo sokuguquguquka kokushisa. Ekuhlolweni, sikhethe izisekelo zomshini wokulinganisa we-granite ne-cast iron ezintathu ezinencazelo efanayo, silingisa ukukhiqizwa kokushisa ngesikhathi sokusebenza kwemishini ngaphansi kwendawo efanayo, futhi sasebenzisa umthwebuli wezithombe ezishisayo ukurekhoda izinguquko zokushisa kanye nezinqubo zokuguquguquka kokushisa kokubili.

Isisekelo sensimbi ephonswe ngensimbi: Ukuguquguquka okukhulu kokushisa kanye nokuqina okukhathazayo

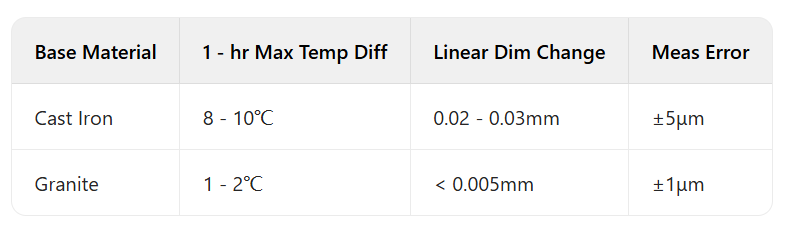

Isithombe sokushisa sibonisa ukuthi ngemva kokuba isisekelo sensimbi esibunjiwe sesisebenze imizuzu engama-30, kuba nokusatshalaliswa okungalingani okukhulu kokushisa kobuso. Ngenxa yokushisa okungalingani kwensimbi esibunjiwe, izinga lokushisa endaweni yendawo yesisekelo likhuphuka ngokushesha, futhi umehluko phakathi kwamazinga okushisa aphezulu naphansi kakhulu ungafinyelela ku-8-10 ℃. Ngaphansi kwesenzo sokucindezeleka kokushisa, isisekelo sensimbi esibunjiwe sidlula ekuguquguqukeni okuncane okubonakala emehlweni enyama. Kwatholakala ngemishini yokulinganisa enembile kakhulu ukuthi ushintsho ngobukhulu bayo obuqondile lufinyelele ku-0.02-0.03mm. Lokhu kuguquka kungabangela iphutha lokulinganisa ukuthi lande liye ku-±5μm, okuthinta kakhulu ukunemba kokulinganisa. Ngaphezu kwalokho, ngemva kokuba isisekelo sensimbi esibunjiwe siyeke ukusebenza, ukushisa kuyanyamalala kancane futhi kuthatha isikhathi esingamahora angu-1 kuya kwangu-2 ukubuyela esimweni sokuqala, okunciphisa kakhulu amandla okusebenza okuqhubekayo kwemishini.

Isisekelo se-granite: Ukuqina okuhle kakhulu kokushisa kuqinisekisa ukunemba kokulinganisa

Ngokuphambene kakhulu, isisekelo se-granite sibonisa ukuzinza okuhle kakhulu kokushisa ngesikhathi sokusebenza. Izithombe zezithombe zokushisa zibonisa ukuthi ukusatshalaliswa kokushisa kobuso kuyafana. Ngemva kwehora elilodwa lokusebenza, umehluko omkhulu wokushisa ebusweni besisekelo ungu-1-2 ℃ kuphela. Lokhu kubangelwa yi-coefficient ephansi kakhulu yokwanda kokushisa kwe-granite (5-7 ×10⁻⁶/℃) kanye nokufana kwayo okuhle kakhulu kokuqhuba ukushisa. Ngemva kokuhlola, ukushintshashintsha kobukhulu obuqondile besisekelo se-granite ngaphansi kwezimo ezifanayo zokusebenza kungaphansi kuka-0.005mm, futhi iphutha lokulinganisa lingalawulwa ngaphakathi kuka-±1μm. Ngisho nangemva kokusebenza okuqhubekayo isikhathi eside, isisekelo se-granite sisengagcina isimo esizinzile, futhi ngemva kokuma kokusebenza, izinga lokushisa libuyela ngokushesha esimweni esizinzile, linikeze ireferensi ethembekile yokulinganisa okulandelayo.

Ngokusebenzisa isethulo esinembile kanye nokuqhathaniswa kwedatha yesithombe esishisayo, inzuzo ye-granite ekuzinzeni kokushisa isobala. Kumabhizinisi akhiqizayo aphishekela ukulinganisa okunembe kakhulu, ukukhetha umshini wokulinganisa onama-three coordinate onesisekelo se-granite kunganciphisa ngempumelelo amaphutha okulinganisa abangelwa ukuguqulwa kokushisa futhi kuthuthukise ukunemba nokusebenza kahle kokuhlolwa komkhiqizo. Njengoba imboni yokukhiqiza iqhubekela phambili ekuqondeni okuphezulu nasekuhlakanipheni, izisekelo ze-granite, ngokuqina kwazo okuvelele kokushisa, nakanjani zizoba yizinto ezikhethwayo zemishini yokulinganisa enama-three coordinate kanye nemishini enembile kakhulu, okuqhuba izinga lokulawula ikhwalithi yemboni liye ekuphakameni okusha.

Isikhathi sokuthunyelwe: Meyi-13-2025