Emkhakheni wokukhiqiza we-semiconductor, ukusika i-wafer kuyinqubo ebalulekile edinga ukunemba okukhulu. Ukukhetha izinto zokwakha imishini kuthinta kakhulu ukusebenza. Ake siqhathanise i-granite nezinye izinto ezivamile ukuze sibone ukuthi kungani ivame ukuphuma phezulu kwemishini yokusika i-wafer.

I-Granite: I-Cut Ngaphezu Kokunye

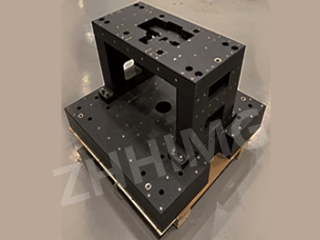

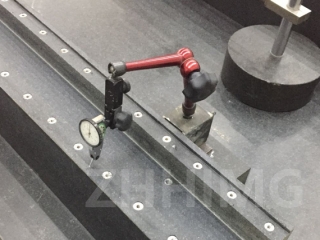

Ukuzinza: I-Granite, enobukhulu obungu-3100 kg/m³ njengokunikezwa yi-ZHHIMG®, inikeza ukuzinza okumangalisayo. Isakhiwo sayo esizinzile sinciphisa ukudlidliza ngesikhathi senqubo yokusika i-wafer. Ngokuphambene nalokho, izinto ezifana ne-aluminium zingase zithambekele kakhulu ekunyakazeni ngaphansi kokucindezeleka kwemisebenzi yokusika ngesivinini esikhulu. Lokhu kuzinza kuqinisekisa ukuthi ithuluzi lokusika lihlala libekwe kahle, okuholela ekusikeni okunembile kanye nama-wafer ekhwalithi ephezulu.

Ukumelana Nokushisa: I-Granite ine-coefficient yokukhulisa ukushisa ephansi. Ekusikeni kwe-wafer, lapho ukuguquguquka kwezinga lokushisa kungenzeka ngenxa yokushisa okubangelwa inqubo yokusika noma indawo yokukhiqiza, ukuzinza kokushisa kwe-granite kuyinzuzo. Ayikhuli noma inciphe kakhulu ngokushintsha kwezinga lokushisa, okugcina ukuhambisana kwemishini yokusika. Izinsimbi ezifana nensimbi, ngakolunye uhlangothi, zingaba nokwanda okukhulu kokushisa, okungase kuholele ekungalinganini kahle nasekusikeni okungalungile.

Ukudambisa Ukudlidliza: Izakhiwo zemvelo zokudlidliza - ukudambisa i-granite ziyamangalisa. Ngesikhathi sokusika i-wafer, ukudlidliza kungabangela ithuluzi lokusika ukuthi liphambuke endleleni yalo ehlosiwe, okuholela ekuqhekekeni noma ekusikeni okungalingani. I-Granite imunca futhi ichithe ngempumelelo lokhu kudlidliza, idale ukusebenza okubushelelezi kokusika. Izinto ezifana nezinhlanganisela ezisekelwe epulasitiki azinalo leli khono lokudlidliza - ukudambisa elingokwemvelo, okwenza zingafaneleki kahle ekusikeni i-wafer ngokunemba okuphezulu.

Ukuqhathanisa ne-Cast Iron

Insimbi ephothiwe ibilokhu iyisinqumo sendabuko sezisekelo zomshini. Kodwa-ke, inemikhawulo yayo uma iqhathaniswa ne-granite. Nakuba insimbi ephothiwe inikeza ukuzinza okuthile, inzima kune-granite uma kuqhathaniswa namandla ayo. Lesi sisindo esengeziwe singadala izinselele ngesikhathi sokufakwa nokunyakaza kwemishini. Ngaphezu kwalokho, insimbi ephothiwe isengozini enkulu yokugqwala ngokuhamba kwesikhathi, ikakhulukazi ezindaweni zokukhiqiza ze-semiconductor lapho kungase kube khona amakhemikhali. I-granite, njengoba ingasebenzisi amakhemikhali, ayihlushwa yile nkinga, iqinisekisa ukuqina nokuthembeka kwesikhathi eside.

Icala Elimelene Nemabula

Abanye bangase bacabangele imabula njengenye indlela, kodwa ayisebenzi kahle ezicini eziningi ngemishini yokusika i-wafer. Imabula inobukhulu obuphansi futhi ngokuvamile ayizinzile kakhulu kune-granite. Iphinde ibe nezimbobo eziningi, okungenza ibe sengozini yokulimala ngenxa yomswakama namakhemikhali endaweni yokukhiqiza. Ekusikeni i-wafer, lapho ukunemba nokuqina kubalulekile khona, izakhiwo zomzimba zemabula azihambisani nezidingo njengoba kwenza i-granite.

Ekuphetheni, uma kukhulunywa ngokukhetha izinto zokwakha izisekelo zemishini yokusika i-wafer, i-granite, ikakhulukazi i-granite yekhwalithi ephezulu njengaleyo enikezwa yi-ZHHIMG®, iyagqama. Ukuqina kwayo, ukumelana nokushisa, kanye namakhono okudlidliza - ukudambisa kwenza kube ukukhetha okuhle kakhulu kokufeza ukunemba okuphezulu okudingekayo ekusikeni i-wafer ye-semiconductor. Nakuba kunezinye izinto ezitholakalayo, inhlanganisela eyingqayizivele yezakhiwo ze-granite iyinika ithuba elicacile kulolu hlelo lokusebenza oludingayo.

Isikhathi sokuthunyelwe: Juni-03-2025