Imboni yokucubungula nokupakisha ukudla incike esisekelweni sokunemba okungapheli. Ingxenye ngayinye, kusukela ku-nozzle yokugcwalisa ngesivinini esikhulu kuya emshinini wokuvala oyinkimbinkimbi, kumele ihlangabezane nokubekezelelana okuqinile kobukhulu ukuqinisekisa ikhwalithi yomkhiqizo, ukunciphisa imfucuza, futhi—okubaluleke kakhulu—iqinisekise ukuphepha kwabathengi. Lokhu kuphakamisa umbuzo oyisisekelo kochwepheshe bokulawula ikhwalithi: Ingabe ipulatifomu ye-granite enembile ifanelekile ukuhlolwa kwezingxenye emishinini yokudla, futhi izidingo zokuhlanzeka zidlala yiphi indima?

Impendulo inguyebo ozwakalayo, i-precision granite ifaneleka kakhulu ekuhlolweni kobukhulu bezingxenye zemishini yokudla, kodwa indawo esetshenziswa kuyo idinga ukucatshangelwa ngokucophelela kwezindinganiso zokuhlanzeka.

Icala le-Granite ekuqondeni kwebanga lokudla

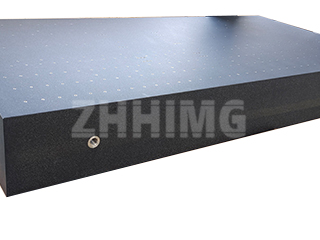

Embindini wayo, i-granite iyinto ekhethwayo ye-metrology ngenxa yezakhiwo zayo ezingokwemvelo, ezivumelana kahle nezimiso eziningana zokuhlanzeka okungenakho ukuxhumana nokudla. I-granite emnyama ephakeme ye-ZHHIMG®, enobukhulu bayo obuphezulu kanye nokwanda okuphansi kokushisa, inikeza isilinganiso sokulinganisa esingenakukwazi ukulingana nensimbi ephonswe noma insimbi engagqwali. Ihlinzeka:

- Ukuzinza Okulinganayo: I-Granite ayisebenzisi amandla kagesi futhi imelana kakhulu nokugqwala nokugqwala, okuyizinzuzo ezibalulekile ezindaweni ezinomswakama ophezulu noma imijikelezo yokuwasha njalo.

- Ukungangcolisi: Ngokungafani nezinsimbi, i-granite ayidingi amafutha avikela ukugqwala futhi ayingcolisi ngokwemvelo. Ngeke isabele ezintweni zokuhlanza ezivamile noma izinsalela ezihlobene nokudla, uma nje indawo inakekelwa kahle.

- Ukuthamba Okuphelele: Amapulatifomu ethu, afinyelela ukuthamba kwezinga le-nanometer kanye nokunamathela ezindinganisweni ezifana ne-ASME B89.3.7, abalulekile ekuhloleni izingxenye ezifana nama-blade okusika ngokunemba, imigqa yokuqondisa yokuhambisa, kanye nama-dies okuvala—izingxenye lapho ukunemba kwe-micron kuqondisa khona ukuphepha kokudla kanye nobuqotho bokusebenza.

Ukuhamba Ngomsebenzi Wokuklama Okuhlanzekile

Nakuba ipuleti lobuso le-granite ngokwalo livame ukusetshenziswa elabhorethri yekhwalithi ehlukanisiwe noma endaweni yokuhlola, inqubo yokuhlola isekela ukuhambisana neziqondiso zokuhlanzeka njengalezo ezibekwe yi-3-A Sanitary Standards noma i-European Hygienic Engineering & Design Group (EHEDG).

Ukukhathazeka okubalulekile kwenhlanzeko yanoma yiliphi ithuluzi lokuhlola kugxile ezimisweni ezimbili: ukuhlanzeka kanye nokungagcini amabhaktheriya. Ukuze uthole i-granite enembile endaweni eseduze nokudla, lokhu kuhunyushwa kube yizinqubo eziqinile zomsebenzisi wokugcina:

- Indawo Engenazo Izimbobo: I-granite ye-ZHHIMG ecolekile inezimbobo ezincane ngokwemvelo. Kodwa-ke, ukunamathela emikhubeni yokuhlanza eqinile ngemishini yokuhlanza yezimboni efanele, engena-asidi kubalulekile ukuvimbela noma yikuphi ukudaya noma ukwakheka kwezinsalela ezincane.

- Ukugwema Ukuthintana: Ipulatifomu yegranite akufanele isetshenziswe njengendawo yokusebenza evamile. Ama-asidi avela kokuchitheka kokudla/iziphuzo ezithile angacwilisa ubuso, adale amachweba amancane okungcola.

- Umklamo Wezingxenye Ezihambisanayo: Uma ipulatifomu yegranite idinga isitendi esinamathiselwe noma amathuluzi ahambisanayo (njengezingcezu noma izinto ezisetshenziswayo), lezi zingxenye zensimbi kumele zenzelwe izindawo ezihlanzekile—okusho ukuthi kumele zihlukaniswe kalula, zibushelelezi, zingamunci, futhi zingabi nemifantu noma amapayipi angenalutho lapho umswakama noma amagciwane anganqwabelana khona.

Ekuphetheni, amapulatifomu e-precision granite ayimpahla ebalulekile yokulawula ikhwalithi yemishini yokudla, esebenza njengereferensi ethembekile eqinisekisa ikhono lomshini lokusebenza ngokuphepha nangokuphumelelayo. Indima ye-ZHHIMG, njengomkhiqizi oqinisekisiwe (i-ISO 9001 kanye nokuhambisana nezindinganiso ze-metrology), ukuhlinzeka ngeplatifomu yokunemba okungenakuphikiswa, okuvumela amakhasimende ethu emishini yokudla ukuthi aqinisekise ngokuqiniseka ukuthi izingxenye zawo—futhi ekugcineni, imikhiqizo yawo—iyahlangabezana nezindinganiso zomhlaba wonke zokuphepha nokunemba.

Isikhathi sokuthunyelwe: Okthoba-22-2025