Ekukhiqizweni kokusika nge-laser ye-LCD/LED, isikhathi sokungasebenzi siyisici esibalulekile esithinta ukusebenza kahle kokukhiqiza kanye nezindleko. Isisekelo se-granite esinembile kakhulu, esinezakhiwo zaso ezihlukile, singanciphisa ngempumelelo isikhathi sokungasebenzi futhi silethe izinzuzo eziningi ekukhiqizweni.

Ukuqina okuvelele kanye nokumelana nokudlidliza

I-Granite inesakhiwo semvelo sokumunca ukudlidliza, futhi isakhiwo sayo sama-molecule singamunca futhi sivimbele ukudlidliza okukhiqizwa ngesikhathi senqubo yokusika i-laser. Lapho kusikwa i-laser ye-LCD/LED, uma ukudlidliza kwemvamisa ephezulu kwemishini (ngokuvamile ephakathi kuka-20 no-50Hz) kungacindezelwa ngempumelelo, kuzoholela ekwehleni kokunemba kokusika, kubangele imikhiqizo enephutha noma elahliwe, bese kudinga ukuthi umshini uvalwe ukuze kulungiswe kabusha futhi kulungiswe amapharamitha. Isisekelo se-granite esinembile kakhulu singanciphisa ubukhulu bokudlidliza ngaphezu kuka-60%, sigcine ikhanda lokusika i-laser lizinzile ngesikhathi sokusebenza ngesivinini esikhulu, senze unqenqema olusezingeni eliphezulu lube lula, kunciphise kakhulu izinkinga zekhwalithi yokusika ezibangelwa ukudlidliza, futhi kugweme ukuvalwa okuvamile kokulungiswa.

I-coefficient ephansi kakhulu yokwanda kokushisa

Ngesikhathi senqubo yokusika nge-laser ye-LCD/LED, kukhiqizwa ukushisa futhi izinga lokushisa elizungezile lingase lishintshe, okubonisa ukuhlolwa kokuqina kokushisa kwesisekelo semishini. Izinto ezivamile zine-coefficient ephezulu yokwanda kokushisa futhi zivame ukuguquka lapho izinga lokushisa lishintsha, okuthinta ukunemba kokusika. I-coefficient yokwanda kokushisa kwe-granite ingu-1/20 kuphela kunensimbi. Ngisho nasendaweni enobubanzi obukhulu bokushintshashintsha kokushisa (njenge--20℃ kuya ku-50℃), isengagcina ukunemba kokubeka ngaphakathi kuka-±2μm. Lokhu kuqinisekisa ukuthi ngesikhathi sokusika okuqhubekayo isikhathi eside, ngeke kube nokuvalwa okuvamile ukuze kuphinde kulinganiswe indlela yokusika kanye nesikhundla ngenxa yokuguquguquka kokushisa kwesisekelo, okuqinisekisa ukuhambisana nokuqina kokunemba kokusika.

Ukumelana nokuguguleka okuphezulu kanye nokuphila isikhathi eside kwenkonzo

Isisekelo se-granite esinembile kakhulu sinobulukhuni obuphezulu kanye nokumelana nokuguguleka okunamandla, kanye nobunzima be-Mohs obungu-6-7, okuphindwe kathathu ukumelana nokuguguleka kunensimbi evamile. Ngesikhathi sokusebenza kwesikhathi eside kanye nemvamisa ephezulu yemishini yokusika nge-laser, ubuso besisekelo abuguguleki. Uma kuqhathaniswa nezinye izinto eziyisisekelo ezigugulekayo, izisekelo ze-granite azidingi ukulungiswa noma ukushintshwa njalo ngenxa yokuguguleka kwendawo, okwandisa impilo yesevisi iyonke yemishini futhi kunciphisa isikhathi sokungasebenzi esingahleliwe sokulungiswa okubangelwa izinkinga zokuguguleka kwesisekelo.

Ukucubungula okunembe kakhulu kanye nokuzivumelanisa nezimo

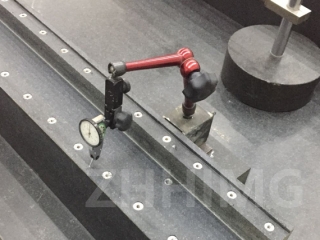

Izisekelo ze-granite ezisezingeni eliphezulu zanamuhla zisebenzisa amasu okucubungula athuthukile, njengomshini we-CNC onama-axis amahlanu, njll. Izinkomba zokunemba ezifana nokuba yisicaba kanye nokuqondile ziphakeme kakhulu, futhi ukuba yisicaba kungafinyelela ku-±0.5μm/m. Lokhu kucubungula okunembe kakhulu kunganikeza ireferensi yokufaka enembile yemishini yokusika nge-laser, okwenza ukunemba kokuhlanganiswa kwengxenye ngayinye yemishini kube phezulu kanye nokusebenza kuzinze kakhudlwana. Okwamanje, isisekelo se-granite singaphinde senziwe ngezifiso futhi sicutshungulwe ngokwezidingo zemishini ehlukene yokusika nge-laser, kufezwe ukuhambisana okuphelele nemishini futhi kuncishiswe ukwehluleka kokusebenza kanye nesikhathi sokungasebenzi sokulungisa amaphutha okubangelwa ukungalingani phakathi kwesisekelo nemishini.

Ukugcinwa okulula nokuqapha okuhlakaniphile

Ezinye izisekelo ze-granite ezinembe kakhulu zihlonyiswe ngezinhlelo zokuqapha ezihlakaniphile ezingaqoqa idatha yesikhathi sangempela njengokudlidliza, izinga lokushisa kanye nokucindezeleka kwezisekelo. Ngokuhlaziya le datha, izingozi zokuhluleka ezingaba khona zingabikezelwa kusengaphambili, futhi ukulungiswa kungahlelwa ngaphambi kokuba kwenzeke amaphutha, kugwenywe isikhathi sokungasebenzi esibangelwa ukwehluleka okungazelelwe. Ngaphezu kwalokho, isisekelo se-granite ngokwaso sinesakhiwo esizinzile kanye nokumelana nokugqwala okunamandla. Ukugcinwa kwaso kwansuku zonke kulula kakhulu, ngaphandle kwesidingo sezinqubo zokulungisa eziyinkimbinkimbi, okunciphisa kakhulu isikhathi sokungasebenzi kokugcinwa.

Isisekelo se-granite esinembile kakhulu sinikeza iziqinisekiso zokusebenza okuzinzile nokusebenza kahle kokukhiqizwa kokusika nge-laser ye-LCD/LED ezicini eziningi, kunciphisa kakhulu isikhathi sokungasebenzi, kuthuthukisa ukusebenza kahle kokukhiqiza, kanye nokwehlisa izindleko zokukhiqiza zizonke. Kuyisinqumo esifanele semishini yesimanje yokusika nge-laser ye-LCD/LED. Isisekelo se-granite esinembile kakhulu: Sinciphisa kakhulu isikhathi sokungasebenzi kokusika nge-laser ye-LCD/LED

Ekukhiqizweni kokusika nge-laser ye-LCD/LED, isikhathi sokungasebenzi siyisici esibalulekile esithinta ukusebenza kahle kokukhiqiza kanye nezindleko. Isisekelo se-granite esinembile kakhulu, esinezakhiwo zaso ezihlukile, singanciphisa ngempumelelo isikhathi sokungasebenzi futhi silethe izinzuzo eziningi ekukhiqizweni.

Ukuqina okuvelele kanye nokumelana nokudlidliza

I-Granite inesakhiwo semvelo sokumunca ukudlidliza, futhi isakhiwo sayo sama-molecule singamunca futhi sivimbele ukudlidliza okukhiqizwa ngesikhathi senqubo yokusika i-laser. Lapho kusikwa i-laser ye-LCD/LED, uma ukudlidliza kwemvamisa ephezulu kwemishini (ngokuvamile ephakathi kuka-20 no-50Hz) kungacindezelwa ngempumelelo, kuzoholela ekwehleni kokunemba kokusika, kubangele imikhiqizo enephutha noma elahliwe, bese kudinga ukuthi umshini uvalwe ukuze kulungiswe kabusha futhi kulungiswe amapharamitha. Isisekelo se-granite esinembile kakhulu singanciphisa ubukhulu bokudlidliza ngaphezu kuka-60%, sigcine ikhanda lokusika i-laser lizinzile ngesikhathi sokusebenza ngesivinini esikhulu, senze unqenqema olusezingeni eliphezulu lube lula, kunciphise kakhulu izinkinga zekhwalithi yokusika ezibangelwa ukudlidliza, futhi kugweme ukuvalwa okuvamile kokulungiswa.

I-coefficient ephansi kakhulu yokwanda kokushisa

Ngesikhathi senqubo yokusika nge-laser ye-LCD/LED, kukhiqizwa ukushisa futhi izinga lokushisa elizungezile lingase lishintshe, okubonisa ukuhlolwa kokuqina kokushisa kwesisekelo semishini. Izinto ezivamile zine-coefficient ephezulu yokwanda kokushisa futhi zivame ukuguquka lapho izinga lokushisa lishintsha, okuthinta ukunemba kokusika. I-coefficient yokwanda kokushisa kwe-granite ingu-1/20 kuphela kunensimbi. Ngisho nasendaweni enobubanzi obukhulu bokushintshashintsha kokushisa (njenge--20℃ kuya ku-50℃), isengagcina ukunemba kokubeka ngaphakathi kuka-±2μm. Lokhu kuqinisekisa ukuthi ngesikhathi sokusika okuqhubekayo isikhathi eside, ngeke kube nokuvalwa okuvamile ukuze kuphinde kulinganiswe indlela yokusika kanye nesikhundla ngenxa yokuguquguquka kokushisa kwesisekelo, okuqinisekisa ukuhambisana nokuqina kokunemba kokusika.

Ukumelana nokuguguleka okuphezulu kanye nokuphila isikhathi eside kwenkonzo

Isisekelo se-granite esinembile kakhulu sinobulukhuni obuphezulu kanye nokumelana nokuguguleka okunamandla, kanye nobunzima be-Mohs obungu-6-7, okuphindwe kathathu ukumelana nokuguguleka kunensimbi evamile. Ngesikhathi sokusebenza kwesikhathi eside kanye nemvamisa ephezulu yemishini yokusika nge-laser, ubuso besisekelo abuguguleki. Uma kuqhathaniswa nezinye izinto eziyisisekelo ezigugulekayo, izisekelo ze-granite azidingi ukulungiswa noma ukushintshwa njalo ngenxa yokuguguleka kwendawo, okwandisa impilo yesevisi iyonke yemishini futhi kunciphisa isikhathi sokungasebenzi esingahleliwe sokulungiswa okubangelwa izinkinga zokuguguleka kwesisekelo.

Ukucubungula okunembe kakhulu kanye nokuzivumelanisa nezimo

Izisekelo ze-granite ezisezingeni eliphezulu zanamuhla zisebenzisa amasu okucubungula athuthukile, njengomshini we-CNC onama-axis amahlanu, njll. Izinkomba zokunemba ezifana nokuba yisicaba kanye nokuqondile ziphakeme kakhulu, futhi ukuba yisicaba kungafinyelela ku-±0.5μm/m. Lokhu kucubungula okunembe kakhulu kunganikeza ireferensi yokufaka enembile yemishini yokusika nge-laser, okwenza ukunemba kokuhlanganiswa kwengxenye ngayinye yemishini kube phezulu kanye nokusebenza kuzinze kakhudlwana. Okwamanje, isisekelo se-granite singaphinde senziwe ngezifiso futhi sicutshungulwe ngokwezidingo zemishini ehlukene yokusika nge-laser, kufezwe ukuhambisana okuphelele nemishini futhi kuncishiswe ukwehluleka kokusebenza kanye nesikhathi sokungasebenzi sokulungisa amaphutha okubangelwa ukungalingani phakathi kwesisekelo nemishini.

Ukugcinwa okulula nokuqapha okuhlakaniphile

Ezinye izisekelo ze-granite ezinembe kakhulu zihlonyiswe ngezinhlelo zokuqapha ezihlakaniphile ezingaqoqa idatha yesikhathi sangempela njengokudlidliza, izinga lokushisa kanye nokucindezeleka kwezisekelo. Ngokuhlaziya le datha, izingozi zokuhluleka ezingaba khona zingabikezelwa kusengaphambili, futhi ukulungiswa kungahlelwa ngaphambi kokuba kwenzeke amaphutha, kugwenywe isikhathi sokungasebenzi esibangelwa ukwehluleka okungazelelwe. Ngaphezu kwalokho, isisekelo se-granite ngokwaso sinesakhiwo esizinzile kanye nokumelana nokugqwala okunamandla. Ukugcinwa kwaso kwansuku zonke kulula kakhulu, ngaphandle kwesidingo sezinqubo zokulungisa eziyinkimbinkimbi, okunciphisa kakhulu isikhathi sokungasebenzi kokugcinwa.

Isisekelo se-granite esinembile kakhulu sinikeza iziqinisekiso zokusebenza okuzinzile nokuphumelelayo kokukhiqizwa kokusika nge-laser ye-LCD/LED ezicini eziningi, kunciphisa kakhulu isikhathi sokungasebenzi, kuthuthukisa ukusebenza kahle kokukhiqiza, kanye nokwehlisa izindleko zokukhiqiza zizonke. Kuyisinqumo esifanele semishini yesimanje yokusika nge-laser ye-LCD/LED.

Isikhathi sokuthunyelwe: Juni-17-2025