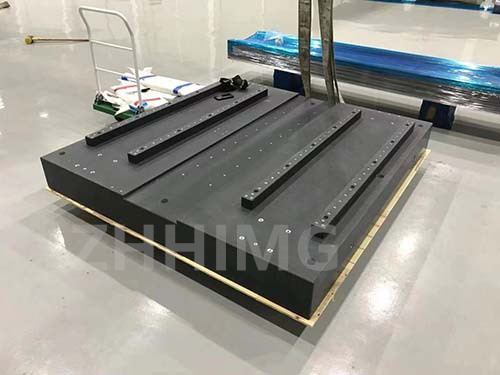

Izingxenye zegranite zisetshenziswa kabanzi embonini yokukhiqiza njengoba zinikeza ukuzinza okuphezulu nokunemba. Imishini yokulinganisa emithathu (i-CMM) ingenye yamathuluzi amaningi okukhiqiza asebenzisa izingxenye zegranite. Ukusetshenziswa kwezingxenye zegranite kuma-CMM kuqinisekisa ukulinganiswa okunembile ngenxa yezakhiwo zazo zemvelo njengokuqina okuphezulu, ukuqina, kanye nokuqina kokushisa. Lezi zakhiwo zenza izingxenye zegranite zibe zilungele imishini yokulinganisa edinga ukunemba okuphezulu nokulinganisa okunembile.

Enye yezinzuzo ezibalulekile zokusebenzisa izingxenye zegranite kuma-CMM ukumelana kwazo nokuguguleka. Igranite iyitshe lemvelo eliqinile nelihlala isikhathi eside futhi laziwa kakhulu ngamandla alo kanye nokumelana nokuguguleka. Izingxenye zegranite ezisetshenziswa kuma-CMM zingamelana nezimo zokusebenza ezinzima, okuhlanganisa nokudlidliza kanye nengcindezi, ngaphandle kokubonisa izimpawu zokuguguleka noma ukuguquka. Ukumelana nokuguguleka kwezingxenye zegranite kuqinisekisa ukuthi azidingi ukushintshwa njalo, okugcina kunciphisa izindleko zokulungisa futhi kwandisa isikhathi sokusebenza komshini.

Ngaphezu kwalokho, izingxenye zegranite azinakekelwa kahle. Zidinga ukunakekelwa okuncane, futhi ngokunakekelwa okufanele kanye nokuhlanzwa njalo, zingagcina ukunemba kwazo nokunemba kwazo iminyaka eminingi. Ukusetshenziswa kwezingxenye zegranite kuma-CMM kuqinisekisa ukuthi umshini ugcina ukunemba kwawo, okuholela emaphutheni ambalwa okulinganisa kanye nemiphumela ephindaphindwayo ethuthukisiwe.

Ngaphezu kokumelana nokuguguleka kanye nokuqina okuhle kakhulu, izingxenye zegranite zinikeza ukumelana kwemvelo ekuguqukeni okubangelwa ukushintshashintsha kwezinga lokushisa. I-coefficient ephansi yokwanda kokushisa (i-CTE) yegranite iqinisekisa ukuthi ukunemba kokulinganisa kuhlala kufana kungakhathaliseki ukuthi izinga lokushisa linjani endaweni yokusebenza. I-CTE ephansi yenza igranite ibe yindawo ekahle yokusetshenziswa kuma-CMM adinga izinqubo zokulinganisa eziqondile kanye nokuqina okuhle kakhulu.

Ekuphetheni, ukusetshenziswa kwezingxenye zegranite kuma-CMM kuqinisekisa ukunemba okuphezulu nokuzinza, futhi isidingo sokushintsha sincane kakhulu. Ukumelana nokuguguleka, ukugcinwa okuphansi, kanye nokumelana kwemvelo nokuguqulwa okubangelwa ukushintshashintsha kwezinga lokushisa kwenza izingxenye zegranite zilungele ukusetshenziswa kuma-CMM, nakwezinye izimboni eziningi ezidinga izinqubo zokukhiqiza ezinembile kakhulu. Izinzuzo zezingxenye zegranite kuma-CMM zifaka phakathi ukusebenza kahle okuphezulu, ukulawulwa kwekhwalithi okuthuthukisiwe, kanye nesikhathi esincishisiwe sokungasebenzi, ekugcineni okuholela ekukhiqizweni okuthuthukisiwe kanye nenzuzo.

Isikhathi sokuthunyelwe: Ephreli-02-2024