Esimweni sanamuhla sokukhiqiza esisezingeni eliphezulu, ukunemba akuseyona inzuzo yokuncintisana—kuyisidingo esiyisisekelo. Njengoba izimboni ezifana nezindiza, ukwenziwa kwe-semiconductor, i-photonics, kanye ne-metrology ethuthukisiwe ziqhubeka nokucindezela imikhawulo yokunemba, izinto ezisetshenziswa ngaphakathi kwezinhlelo zokulinganisa kanye nemishini yokukhanya sezibaluleke kakhulu njenge-algorithms yesofthiwe noma izinhlelo zokulawula. Yilapho izixazululo ze-ceramic zezimboni, okuhlanganisai-ceramic enembile ye-CMM, i-ceramic enembile ye-photonics, kanye ne-ceramic ye-SiN enembile ethuthukisiwe, zidlala indima ebaluleke kakhulu.

Izinto zobumba zezimboni zithuthuke kakhulu ngale komfanekiso wazo wendabuko njengezingxenye ezilula ezingagugi. Izinto zobumba zesimanje zobuchwepheshe ziyizinto ezakhiwe ngezakhiwo ezincane ezilawulwa ngokucophelela, ezinikeza ukusebenza okubikezelwayo kwemishini, ukushisa, kanye namakhemikhali. Uma kuqhathaniswa nezinsimbi, izinto zobumba zinikeza ukuzinza okuphezulu kobukhulu, ukwanda okuphansi kokushisa, kanye nokumelana okuhle kakhulu nokugqwala nokuguga. Lezi zici zibaluleke kakhulu ezindaweni lapho ama-micron—noma ngisho nama-nanometer—ebalulekile khona.

Emishinini yokulinganisa ehlanganisiwe, noma ama-CMM, ukuzinza kwesakhiwo kuyisisekelo sokulinganisa okuthembekile. Noma yikuphi ukuguqulwa kokushisa, ukudlidliza, noma ukukhukhuleka kwezinto zesikhathi eside kungahumusha ngokuqondile kube ukungaqiniseki kokulinganisa.I-ceramic eqondile ye-CMMizinhlelo zokusebenza zibhekana nalezi zinselele ezingeni lezinto ezibonakalayo. Amabhuloho e-ceramic, imigwaqo, izisekelo, kanye nezingxenye zesakhiwo zigcina i-geometry yazo ngokuhamba kwesikhathi, ngisho nangaphansi kwamazinga okushisa ashintshashintshayo. Lokhu kuzinza kuvumela izinhlelo ze-CMM ukuthi zilethe imiphumela yokulinganisa ehambisanayo ngaphandle kokunxeshezelwa ngokweqile kwemvelo noma ukulinganiswa kabusha okuvamile.

Ngokungafani nezakhiwo ze-granite noma zensimbi zendabuko, izingxenye ze-ceramic zezimboni ezithuthukisiwe zinikeza ibhalansi eyingqayizivele yokuqina kanye nobunzima obuphansi. Le nhlanganisela ithuthukisa ukusebenza okuguquguqukayo, ivumela isivinini sokuhlola esisheshayo ngenkathi igcina ukunemba kokulinganisa. Njengoba ukuhlolwa okuzenzakalelayo kuba yinto evamile ezimbonini ezihlakaniphile, lokhu kuzinza okuguquguqukayo kuya ngokuya kuba yigugu. I-ceramic enembile yezinhlelo ze-CMM isekela ukukhishwa okuphezulu ngaphandle kokubeka engcupheni ubuqotho bedatha, okwenza ifaneleke kahle ezindaweni zanamuhla zokulawula ikhwalithi.

I-ceramic enembile yezinhlelo zokusebenza ze-photonics ibhekene nesethi yezidingo ezidinga kakhulu. Izinhlelo ze-photonic zincike ekuqondeni okuqondile, ukuqina kwendlela ye-optical, kanye nokumelana nokukhukhuleka kokushisa. Ngisho nezinguquko ezincane zobukhulu zingathinta ukulungelelaniswa kwemisebe, ukuqina kwe-wavelength, noma ubuqotho besignali. Izinto ze-ceramic, ikakhulukazi i-alumina ehlanzekile kakhulu kanye ne-silicon nitride ceramics, zinikeza ukuqina kokushisa kanye nokwemishini okudingekayo ukuze kugcinwe ukulungelelaniswa okuqondile kwe-optical esikhathini eside sokusebenza.

Ezinhlelweni ze-laser, amabhentshi e-optical, kanye namapulatifomu okulinganisa i-photonic, izakhiwo ze-ceramic zisebenza njengezinto ezivumela ukusebenza kahle. I-coefficient yazo ephansi yokwanda kokushisa kusiza ukuqinisekisa ukuthi izingxenye ze-optical zihlala zihambisana naphezu kokushintsha kwezinga lokushisa okubangelwa izimo zemvelo noma ukusebenza kwesistimu. Ngesikhathi esifanayo, izakhiwo zokunciphisa umswakama ezitholakala kuzo ze-ceramics zinciphisa umthelela wokudlidliza, okubalulekile ekulinganisweni kwe-optical okunesinqumo esiphezulu kanye nokucutshungulwa kwe-laser.

I-Precision SiN ceramic, noma i-silicon nitride ceramic, imelela enye yezinhlobo ezithuthuke kakhulu zezinto zobumba zezimboni ezisetshenziswa njengamanje emishinini enembile kakhulu. Yaziwa ngamandla ayo angavamile, ukuqina kokuqhekeka, kanye nokumelana nokushaqeka kokushisa, i-silicon nitride ihlanganisa ukuqina komshini nokuzinza okuvelele kobukhulu. Lezi zakhiwo zenzai-SiN ceramic enembileifaneleka kakhulu izinhlelo zokusebenza ezithwala umthwalo omkhulu, ezisheshayo, noma ezifuna ukushisa okukhulu.

Kwemishini ye-metrology kanye ne-photonics,i-SiN ceramic enembileIzingxenye zivame ukusetshenziswa lapho kokubili ukuqina nokuthembeka kubalulekile khona. Zigcina izakhiwo zazo zemishini ebangeni elibanzi lokushisa futhi ziyamelana nokuguguleka ngisho nasezimweni zokusebenza ezidinga amandla. Lokhu kuthembeka kwesikhathi eside kunciphisa izidingo zokugcinwa futhi kusekela ukusebenza okuzinzile kohlelo kuyo yonke impilo yesevisi yemishini. Kubakhiqizi nabasebenzisi bokugcina ngokufanayo, lokhu kuholela ekuncipheni kwezindleko zobunikazi kanye nokuqiniseka okuphezulu emiphumeleni yokulinganisa.

Ngombono obanzi, ukwamukelwa okwandayo kwezinto zobumba zezimboni kubonisa ushintsho endleleni izinhlelo zokunemba eziklanywe ngayo. Esikhundleni sokukhokha imikhawulo yezinto ezibonakalayo ngesofthiwe eyinkimbinkimbi noma izilawuli zemvelo, onjiniyela bakhetha kakhulu izinto ezisekela ukunemba ngokwemvelo. I-ceramic enembile yezinhlelo zokusebenza ze-CMM kanye ne-photonics ifaka le filosofi ngokunikeza ukuzinza, ukubikezela, kanye nokuqina ezingeni lesakhiwo.

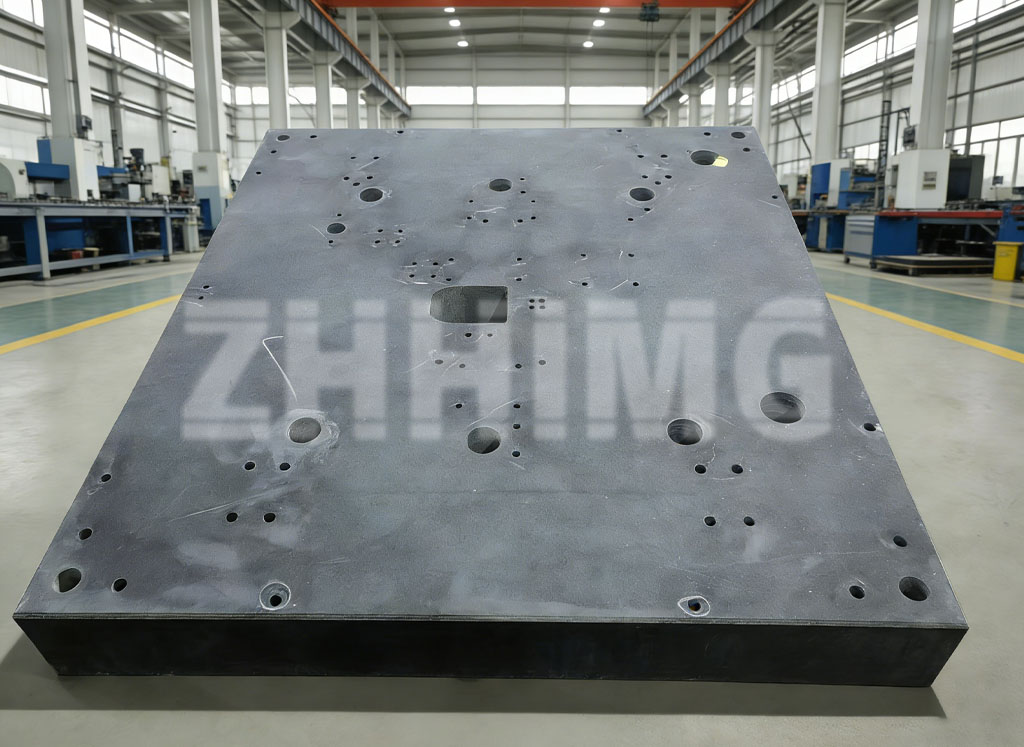

Kwa-ZHHIMG, ubunjiniyela be-ceramic bubhekwa njengomkhakha ohlanganisa isayensi yezinto ezibonakalayo nokukhiqizwa okunembile. Izingxenye ze-ceramic zezimboni aziphathwa njengezingxenye ezijwayelekile, kodwa njengezinto ezibalulekile ezilungiselelwe izinhlelo zokusebenza ezithile. Kungakhathaliseki ukuthi zisetshenziswa ezakhiweni ze-CMM, amapulatifomu e-photonics, noma izinhlelo zokuhlola ezithuthukisiwe, ingxenye ngayinye ye-ceramic yakhiqizwa ngokulawula okuqinile phezu kobucaba, i-geometry, kanye nekhwalithi yobuso. Lokhu kunakwa emininingwaneni kuqinisekisa ukuthi izinzuzo zezinto ezibonakalayo zigcwaliseka ngokugcwele ezinhlelweni zokusebenza zangempela.

Njengoba izimboni ziqhubeka zifuna ukunemba okuphezulu, imijikelezo yokulinganisa esheshayo, kanye nezinhlelo zokukhanya ezithembeke kakhudlwana, indima ye-ceramics ethuthukisiwe izokhula kuphela. Izixazululo ze-ceramic zezimboni, okuhlanganisa i-ceramic enembile ye-CMM, i-ceramic enembile ye-photonics, kanye nezingxenye ze-ceramic ezinembile ze-SiN, aziseyona ubuchwepheshe obukhethekile. Ziba izinto eziyisisekelo zesizukulwane esilandelayo semishini enembile.

Kwabanjiniyela, abaklami bezinhlelo, kanye nabenza izinqumo eYurophu naseNyakatho Melika, ukuqonda inani lezinto zobumba kubalulekile lapho uhlela ukutshalwa kwezimali esikhathini esizayo ku-metrology kanye ne-photonics. Ngokukhetha izixazululo zobumba ezifanele esigabeni sokuklama, kungenzeka ukufeza ukunemba okuphezulu, ukuzinza okukhulu, kanye nokuphila isikhathi eside kwenkonzo—imiphumela esekela ngqo ikhwalithi, ukusebenza kahle, kanye nokuncintisana kwesikhathi eside ekukhiqizeni okuthuthukile.

Isikhathi sokuthunyelwe: Jan-13-2026