Ukulinganisa ngokunemba bekulokhu kuyisici esibalulekile ekukhiqizeni okuthuthukile, kodwa okulindelwe okubekwe ezinhlelweni zokuhlola zesimanje kushintsha ngokushesha. Njengoba inani lokukhiqiza landa, amajiyometri omkhiqizo aba yinkimbinkimbi kakhulu, futhi izidingo zokubekezelelana ziyaqina, izindlela zokuhlola zendabuko azisanele. Lolu shintsho lubeke umshini wokulinganisa ohambisanayo ku-metrology enkabeni yamasu okuqinisekisa ikhwalithi kuzo zonke izimboni zezindiza, izimoto, i-elekthronikhi, kanye nobunjiniyela bokunemba.

Namuhla, i-metrology ayisagcini nje emakamelweni okuhlola angashintshi noma eminyangweni yekhwalithi ehlukanisiwe. Isibe yingxenye ehlanganisiwe yezinhlelo zokukhiqiza ezihlakaniphile, eziqhutshwa ukuzenzekela, ukulawulwa kwedijithali, kanye nokuxhumeka kwedatha. Kulesi simo, ubuchwepheshe obufana ne-CMM yerobhothi, umshini wokulinganisa olawulwa yikhompyutha, kanye nezixazululo zokuhlola eziphathwayo zichaza kabusha ukuthi kwenziwa kanjani futhi kuphi izilinganiso.

Umqondo we-CMM yerobhothi ubonisa ukuthambekela okubanzi kokuzenzakalela kanye nokuguquguquka kokulinganisa. Ngokuhlanganisa ukunyakaza kwerobhothi nobuchwepheshe bokulinganisa obuhambisanayo, abakhiqizi bangafinyelela umphumela ophezulu ngenkathi begcina ukunemba kokuhlola okuqhubekayo.Izinhlelo zamarobhothizibaluleke kakhulu ezindaweni zokukhiqiza lapho imisebenzi yokulinganisa ephindaphindwayo kumele yenziwe ngokwethembeka futhi ngaphandle kokungenelela komuntu okuningi. Uma zihlanganiswe kahle, izixazululo ze-CMM ezisekelwe kurobhothi zisekela ukuhlolwa okuqondile, impendulo esheshayo, kanye nezikhathi zomjikelezo ezincishisiwe, konke okunikela ngqo ekuthuthukisweni kokulawulwa kwenqubo.

Enhliziyweni yalezi zixazululo ezizenzakalelayo kukhona umshini wokulinganisa ama-coordinate olawulwa yikhompyutha. Ngokungafani nezinhlelo ezisetshenziswa ngesandla, umshini wokulinganisa ama-coordinate olawulwa yikhompyutha wenza izinqubo zokulinganisa ezihleliwe ngokuphindaphinda okuphezulu kanye nokulandelela. Izindlela zokulinganisa, amasu okuhlola, kanye nokuhlaziywa kwedatha konke kulawulwa yisoftware, okuqinisekisa imiphumela ehambisanayo phakathi kwamashifti, opharetha, kanye namaqoqo okukhiqiza. Leli zinga lokulawula libalulekile kubakhiqizi abasebenza ngaphansi kwezindinganiso zomhlaba wonke eziqinile kanye nezidingo zekhwalithi eziqondene namakhasimende.

Intshisekelo ekhulayo ohlwini lwe-CNC CMM lokuthengisa ezimakethe zomhlaba wonke ibonisa lesi sidingo sokwenza okuzenzakalelayo nokuthembeka. Abathengi abasabheki kuphela ezicacisweni zokunemba; bahlola ukuzinza kwesistimu, ukusebenza kwesikhathi eside, ukuhambisana kwesofthiwe, kanye nokulula kokuhlanganiswa emigqeni yokukhiqiza ekhona. I-CNC CMM imelela ukutshalwa kwezimali ekusebenzeni kahle kwenqubo kanye nekhono lokulinganisa, ikakhulukazi uma ihambisana nezingxenye zesakhiwo eziqinile kanye nezinto eziyisisekelo ezizinzile.

Naphezu kokwanda kwezinhlelo ezizenzakalelayo ngokugcwele, ukuguquguquka kusalokhu kuyinto ebalulekile ekulinganisweni kwesimanje. Yilapho izixazululo ezifana nengalo ephathekayo ye-CMM zidlala khona indima ebalulekile. Izingalo zokulinganisa eziphathekayo zivumela abahloli ukuthi balethe uhlelo lokulinganisa ngqo engxenyeni, kunokuthutha izingxenye ezinkulu noma ezibucayi ziye kwi-CMM ehleliwe. Ezinhlelweni ezibandakanya izinhlangano ezinkulu, ukuhlolwa endaweni, noma isevisi yasensimini, izingalo eziphathekayo zinikeza ikhono lokulinganisa elisebenzayo ngaphandle kokulahlekelwa ukunemba.

Ngaphakathi komshini wokulinganisa obanzi endaweni ye-metrology, lezi zinhlelo eziphathekayo ziyahambisana esikhundleni sokufaka esikhundleni se-CMM yendabuko yohlobo lwebhuloho kanye ne-gantry. Isixazululo ngasinye sifeza injongo ethile, futhi amasu ekhwalithi yesimanje avame ukuhilela inhlanganisela yezinhlelo zokulinganisa ezihleliwe, eziphathekayo, kanye nezenzakalelayo. Inselele isekuqinisekiseni ukuthi yonke idatha yokulinganisa ihlala ihambisana, ilandeleka, futhi ihambisana namazinga ekhwalithi yebhizinisi.

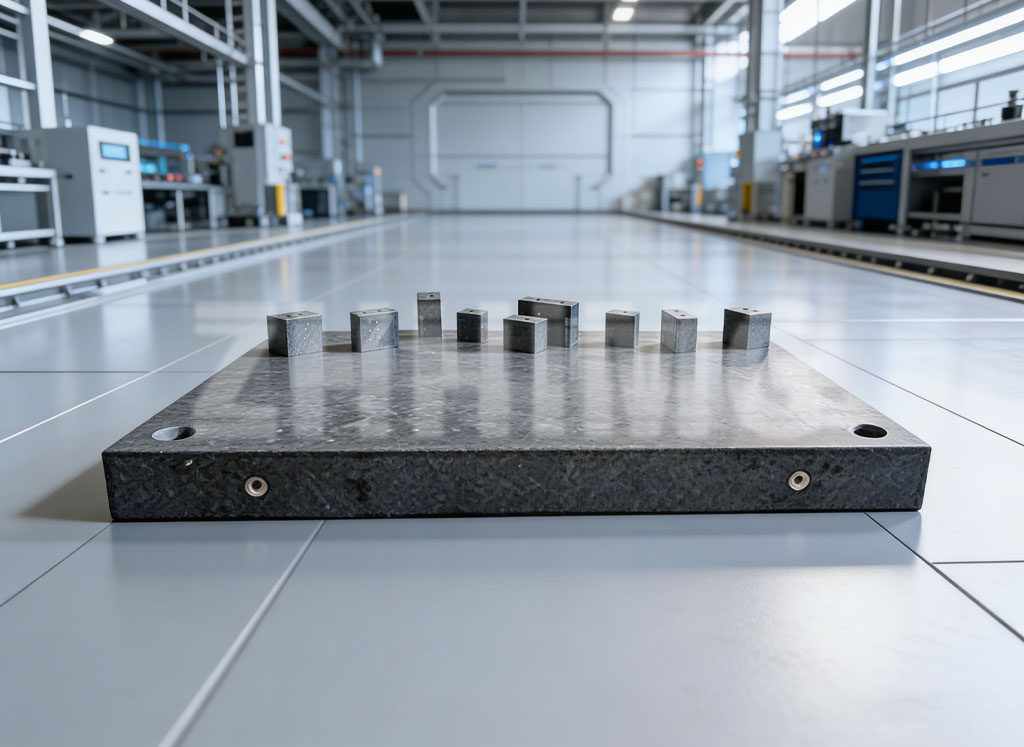

Ukuzinza kwesakhiwo kusalokhu kuyisidingo esiyisisekelo kungakhathaliseki ukucushwa kwe-CMM okukhethiwe. Kungakhathaliseki ukuthi kusekela i-CMM yerobhothi, uhlelo lokuhlola lwe-CNC, noma iseli lokulinganisa elihlanganisiwe, isisekelo semishini sithonya ngqo ukuthembeka kokulinganisa. Izinto ezifana ne-precision granite zisetshenziswa kabanzi ezisekelweni ze-CMM kanye nezingxenye zesakhiwo ngenxa yokwanda kwazo kokushisa okuphansi, ukudambisa okuhle kakhulu kokudlidliza, kanye nokuqina kobukhulu besikhathi eside. Lezi zakhiwo zibaluleke kakhulu emishinini yokulinganisa ezenzakalelayo nelawulwa yikhompyutha, lapho ngisho nokukhukhuleka okuncane kwesakhiwo kungathinta imiphumela yokulinganisa ngokuhamba kwesikhathi.

I-ZHONGHUI Group (ZHHIMG) ibilokhu isekela imboni yomhlaba wonke ye-metrology ngokuhlinzeka ngezingxenye ze-granite ezinembile kanye nezixazululo zesakhiwo zezinhlelo zokulinganisa ezithuthukisiwe. Njengoba inolwazi oluningi ekukhiqizeni okunembile kakhulu, i-ZHHIMG isebenzisana eduze nabakhiqizi be-CMM, abahlanganisi be-automation, kanye nabasebenzisi bokugcina ukulethaizisekelo ze-granite ezenziwe ngokwezifiso, imigwaqo, kanye nezakhiwo zemishini ezenzelwe izindawo zokulinganisa ezidinga amandla. Lezi zingxenye zisetshenziswa kabanzi ekufakweni kwe-robot CMM, izinhlelo zokulinganisa ze-CNC, kanye namapulatifomu okuhlola ahlanganisiwe.

Njengoba ukukhiqizwa kwedijithali kuqhubeka nokuthuthuka, izinhlelo zokulinganisa ziya ngokuya zixhunyaniswa nezinhlelo zokusebenza kokukhiqiza, amapulatifomu okulawula inqubo yezibalo, kanye namawele edijithali. Kulesi simo, indima yomshini wokulinganisa oxhumanisayo ku-metrology idlulela ngale kokuhlola ukuze ibe umthombo wobuhlakani benqubo yesikhathi sangempela. Ukuqoqwa kwedatha okuzenzakalelayo, ukuhlaziywa, kanye nempendulo kuvumela abakhiqizi ukuthi babone ukuphambuka kusenesikhathi futhi bathuthukise amapharamitha okukhiqiza ngendlela ephumelelayo.

Ikusasa le-metrology lizobunjwa yi-automation enkulu, ukwanda kokuhamba, kanye nokulindela okuphezulu kokunemba nokusebenza kahle. Izinhlelo ze-robot CMM zizoqhubeka nokwandisa ukuba khona kwazo ezitezi zokukhiqiza, kuyilapho izingalo eziphathekayo kanye nemishini yokulinganisa elawulwa yikhompyutha izosekela amasu okuhlola aguquguqukayo futhi ahlukaniswe. Kuyo yonke le ndawo eguqukayo, ukubaluleka kwezakhiwo ezizinzile, ukulawula ukunyakaza okunembile, kanye nezinto ezinokwethenjelwa akukashintshi.

Kubakhiqizi abahlola izixazululo ezintsha zokuhlola noma ukuhlola izinketho zokuthengisa ze-CNC CMM, umbono wezinga lesistimu ubalulekile. Ukucaciswa kokunemba kuphela akuchazi ukusebenza. Ukuqina kwesikhathi eside, ukuzivumelanisa nezimo zemvelo, kanye nobuqotho besakhiwo kubaluleke ngokulinganayo ekufinyeleleni imiphumela yokulinganisa ehambisanayo.

Njengoba izimboni ziqhubekela ezindaweni zokukhiqiza ezihlakaniphile nezixhumene kakhulu, imishini yokulinganisa edidiyelwe izohlala iyitshe lesisekelo le-metrology yesimanje. Ngokuhlanganiswa okucatshangelwe kahle kwamarobhothi, ukulawulwa kwamakhompyutha, kanye nezakhiwo eziklanywe ngokunemba, izinhlelo zokulinganisa zanamuhla azigcini nje ngokuhambisana nokusungula izinto ezintsha kodwa zikwenza kube lula.

Isikhathi sokuthunyelwe: Jan-06-2026